Mounting method of elevator shaft shear wall formwork

An installation method and elevator shaft technology, which are applied in the field of formwork for concrete pouring, can solve the problems of inconvenient construction of the elevator shaft concrete structure, unguaranteed safety of operators, poor safety of steel platforms, etc., and achieve safe and reliable project quality, The effect of reducing water seepage hazards and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

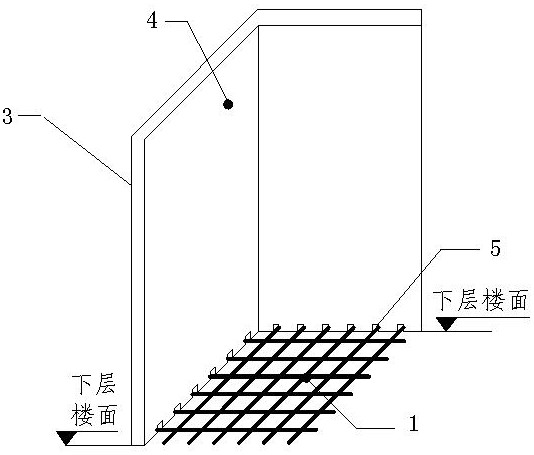

[0030] The installation technological process of elevator shaft shear wall formwork of the present invention:

[0031] Fabrication of reinforcement—installation of steel mesh—concreting of the lower layer—making of upper layer formwork—installation and reinforcement of formwork.

[0032] The installation method of elevator shaft shear wall formwork of the present invention comprises the following steps:

[0033] a. Reinforcement production

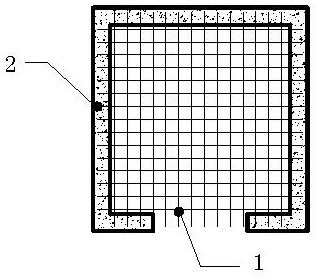

[0034] see now figure 1 , figure 1 It is a schematic diagram of the structure of a straight strip steel bar according to an embodiment of the present invention. As shown in the figure, to determine the net dimension width (B) and depth (L) of the elevator shaft, use φ10mm steel bars to process lengths of B+300mm, L+300mm shaft steel bars 1, and the length of the hooks at both ends is 150mm.

[0035] b. Steel mesh installation

[0036] Weave the steel bars that have been manufactured and processed in a vertical and horizontal crosswise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com