Non-setting adhesive wall sticker manufacturing method convenient to operate

A manufacturing method and an easy-to-operate technology, which can be used in adhesives, building structures, film/sheet-like adhesives, etc., can solve problems such as reducing work efficiency, increasing labor costs, and the inability of automatic finishing of wallpapers to improve work efficiency. , the effect of easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

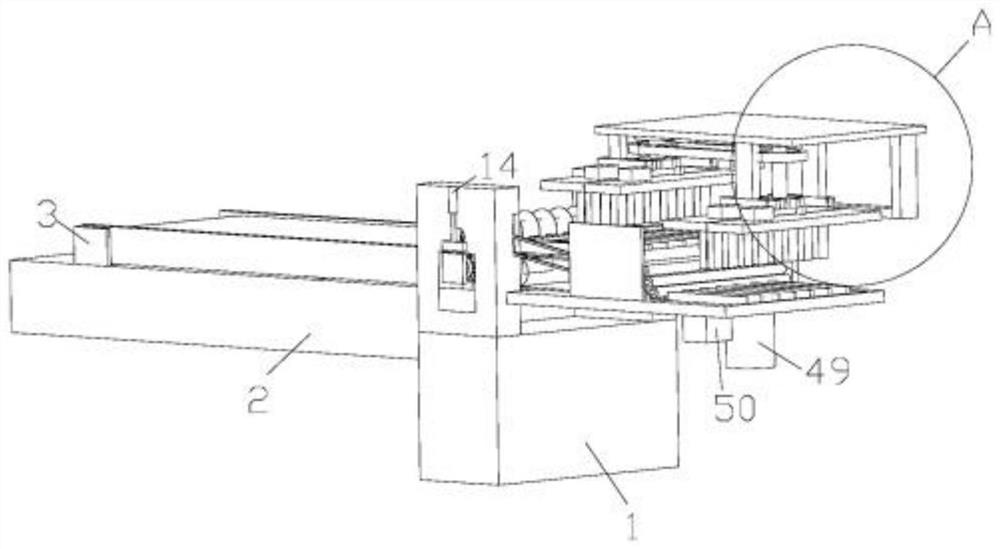

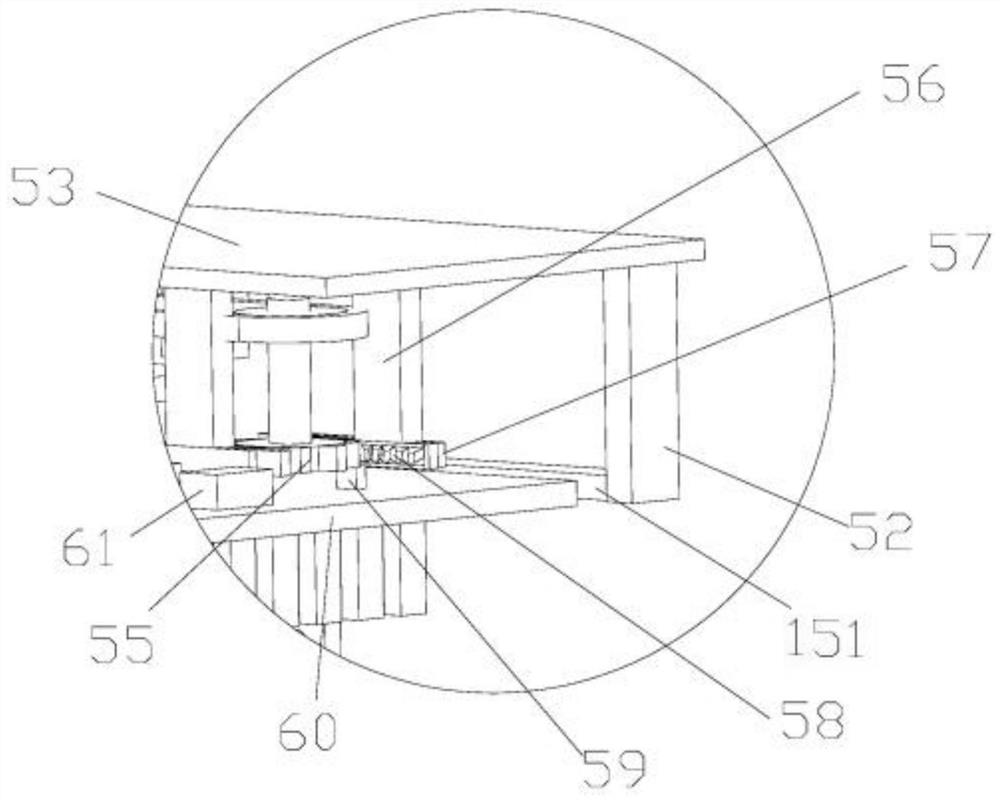

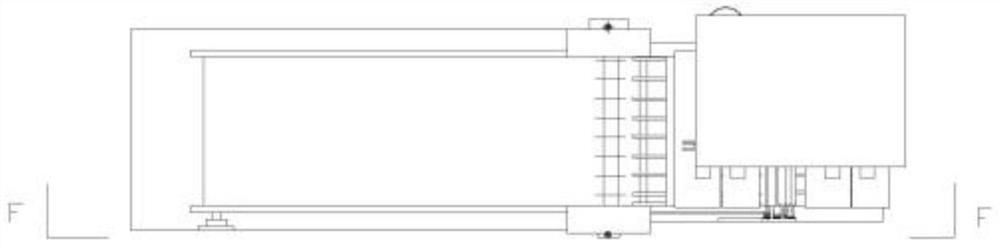

Image

Examples

Embodiment Construction

[0035] An easy-to-operate self-adhesive wall sticker manufacturing method, the steps of the processing method can be divided into,

[0036] a. Unwinding, through the unwinding equipment, the self-adhesive wall sticker base paper rolled into a roll is unfolded and transported to the next process smoothly;

[0037] b. Printing, printing the pattern or text on the base paper of the self-adhesive wall sticker through the printing machine and using the printing plate as a template;

[0038] c. Glazing, apply a layer of varnish on the self-adhesive wall sticker base paper;

[0039] d. Bronzing;

[0040] e. Die cutting, cutting the continuous self-adhesive label base paper into semi-finished products of predetermined length through a cutting machine.

[0041] f. Cut into strips, use the self-adhesive strip cutter to cut the cut semi-finished products into strips.

[0042] The material of the wall sticker base paper includes pulp, modified wood powder, polyvinyl alcohol, nano-alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com