Preparation method of mxene microspheres

A technology of microspheres and nanosheets, applied in the field of preparation of MXene microspheres, can solve the problems affecting the performance advantages of MXene materials, and achieve the effects of good ion accessibility, improved production efficiency, and stacking inhibition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Prepare MXene microspheres, comprising the following steps:

[0018] (1) Take 50 mg of d-Ti with 3 layers and a size of 0.1 μm 3 C 2 The nanosheets were dissolved in 100ml deionized water to form a colloid with an MXene concentration of 0.5mg / ml;

[0019] (2) The prepared MXene colloid is added dropwise to the surface of the monocrystalline silicon substrate, and the diameter of the MXene colloidal microspheres added dropwise to the surface of the monocrystalline silicon substrate is 0.1 mm;

[0020] (3) By drying the colloid at an air flow rate of 0.5 cm / min, MXene microspheres with a diameter of 2 μm can be quickly obtained on the surface of the single crystal silicon substrate.

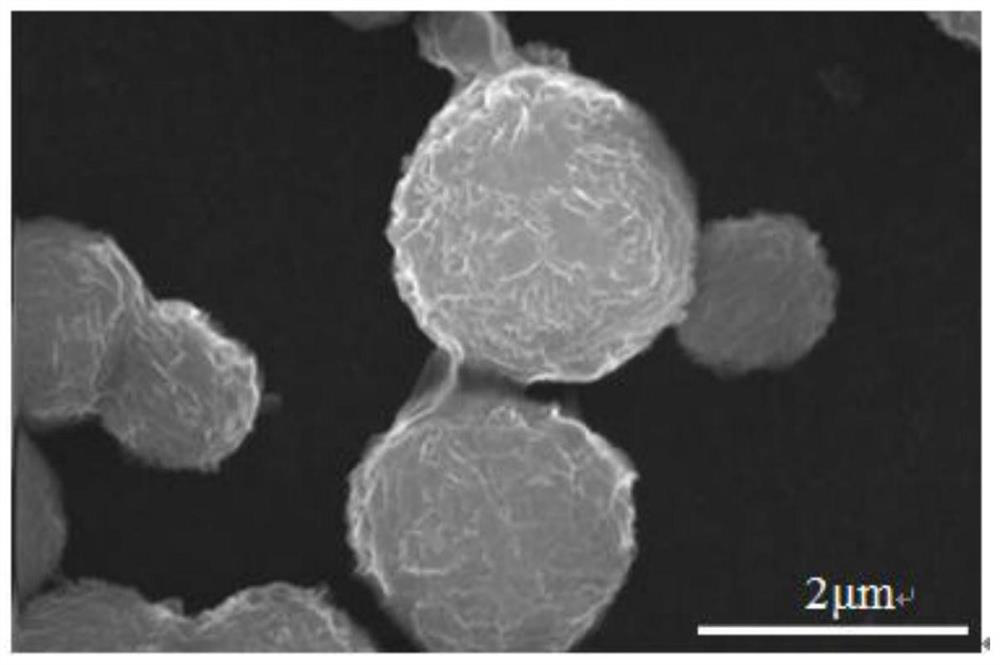

[0021] The prepared MXene microspheres were tested by SEM, and the test results were as follows: figure 1 and 2 as shown, figure 1 It shows that the diameter of the MXene microspheres prepared in Example 1 is about 2 μm, figure 2 It shows that the MXene microspheres prepared in Exampl...

Embodiment 2

[0023] Prepare MXene microspheres, comprising the following steps:

[0024] (1) Take 500 mg of d-Ti with 5 layers and a size of 1 μm 3 C 2 The nanosheets were dissolved in 100ml deionized water to form a colloid with an MXene concentration of 5mg / ml;

[0025] (2) the prepared MXene colloid is added dropwise to the polytetrafluoroethylene matrix surface, and the diameter of the MXene colloid microspheres added dropwise to the polytetrafluoroethylene matrix surface is 1mm;

[0026] (3) By drying the colloid at an air flow rate of 5 cm / min, MXene microspheres with a diameter of 5 μm can be quickly obtained on the surface of the polytetrafluoroethylene substrate.

Embodiment 3

[0028] Prepare MXene microspheres, comprising the following steps:

[0029] (1) Take 1500 mg of d-Ti with 10 layers and a size of 2 μm 3 C 2 The nanosheets were dissolved in 100ml deionized water to form a colloid with an MXene concentration of 15mg / ml;

[0030] (2) The prepared MXene colloid is added dropwise to the PVC-coated cloth substrate surface, and the diameter of the MXene colloid microspheres added dropwise to the PVC-coated cloth substrate surface is 5mm;

[0031] (3) Dry the colloid at an air flow rate of 10 cm / min, and quickly obtain MXene microspheres with a diameter of 10 μm on the surface of the PVC-coated cloth substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com