Coal feeder operation starting method and system for preventing high temperature of coal stored in coal bunker

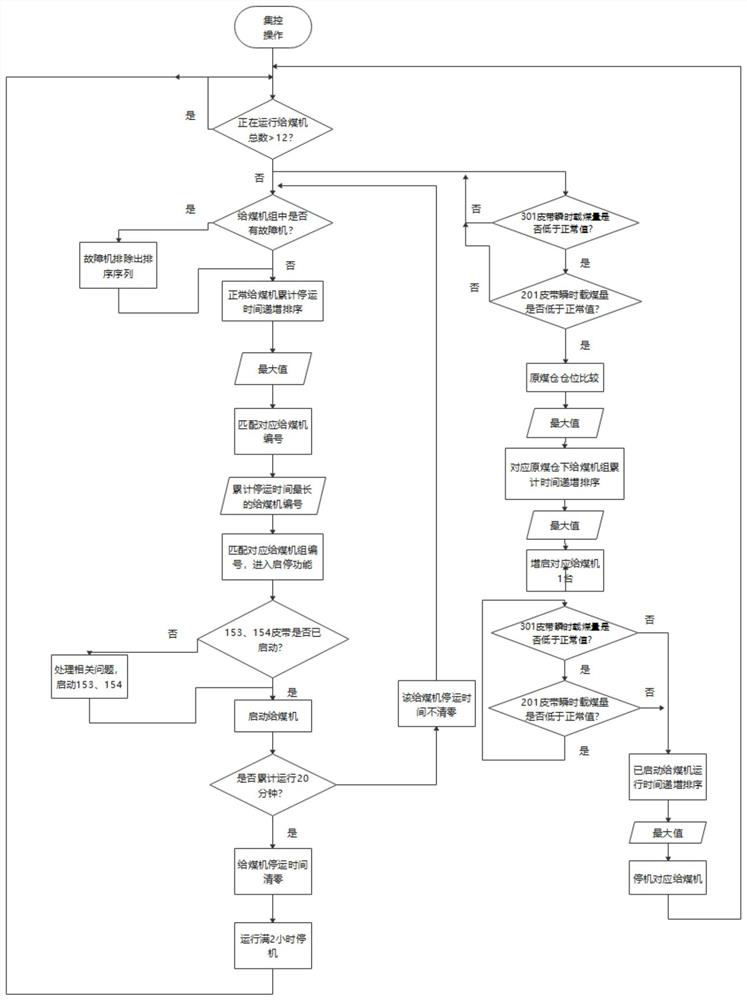

An operation method and technology of a coal feeder, which are applied to conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as fire danger, high temperature of coal storage, and ineffective circulation and replacement of coal feeders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Three raw coal bunkers of a coal preparation plant are arranged side by side, two coal conveying belts (153 belt and 154 belt) are arranged under the raw coal bunker, and 16 coal feeding belts (No. 105-153) are arranged under each raw coal bunker Machines, that is, 8 coal feeders are arranged under each raw coal bunker corresponding to each coal conveyor belt. According to the different washing volumes of the coal preparation plant every day, it is impossible for 48 coal feeders under the raw coal bunker to be put into operation at the same time. Coal feeder start-up operation system for high-temperature coal, including: coal feeder failure status judgment module, coal feeder cumulative outage time judgment module, coal feeder start and stop judgment module, coal amount judgment module, bin position judgment module and coal feeder Accumulated running time judgment module;

[0026] The coal feeder failure state judgment module is used to judge whether the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com