Tool placing rack for constructional engineering

A technology of construction engineering and placing racks, which is applied in the field of racks, can solve problems such as leveling quality doubts, inability to bring convenience, inability to flexibly adjust, etc., and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

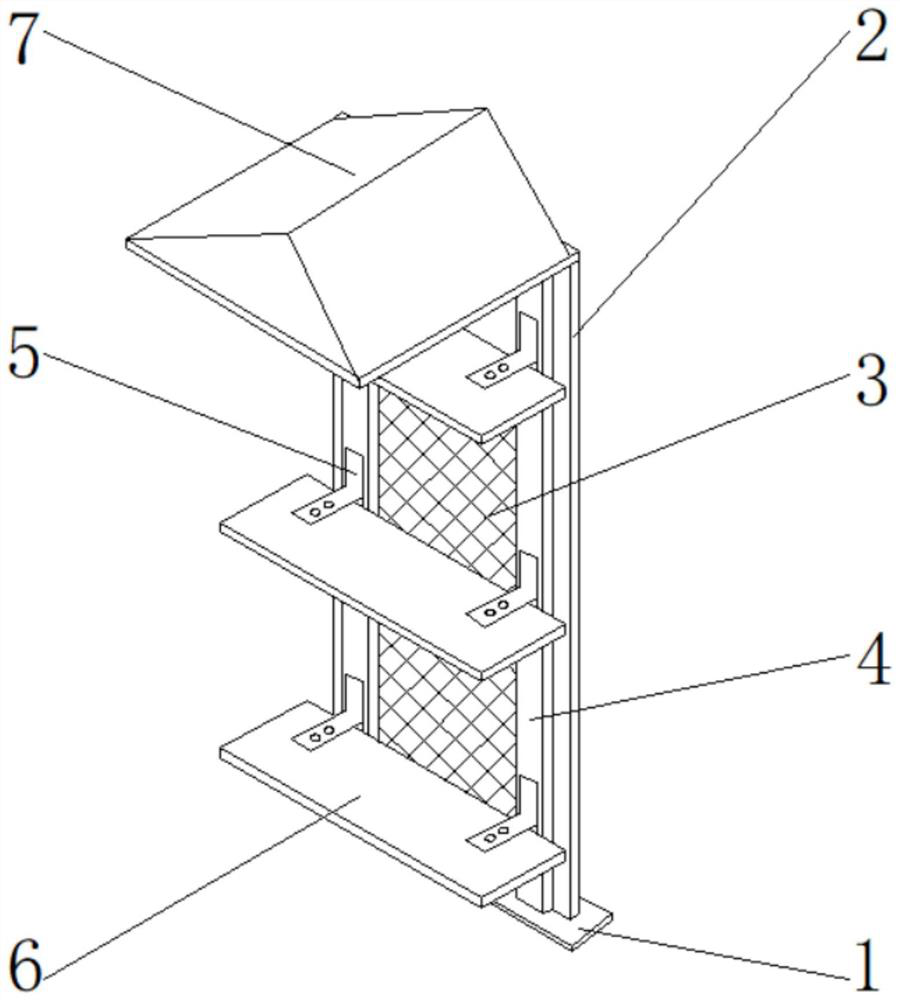

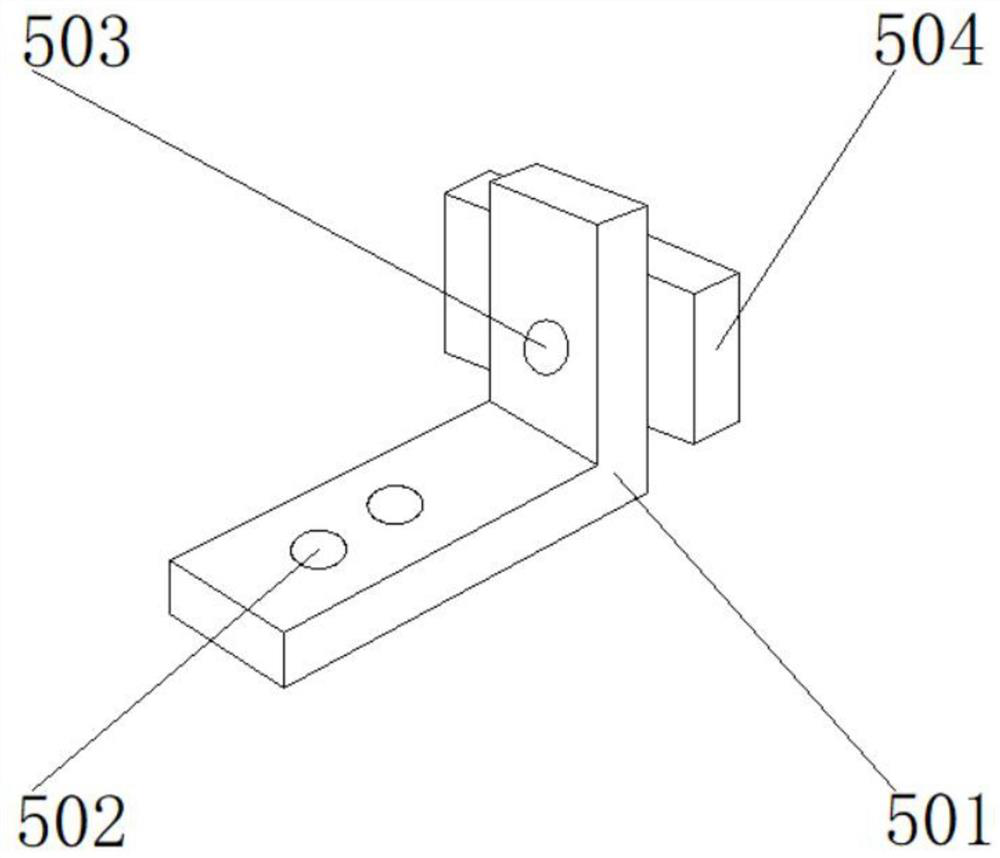

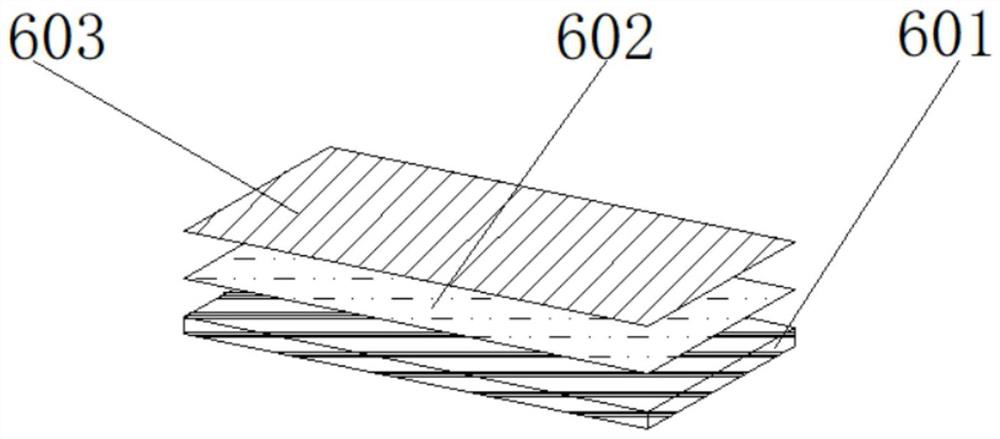

[0024] Such as Figure 1-4 Shown, a kind of tool placement rack for construction engineering, the outer surface of the upper end of the main body 1 is provided with a casing 2, one side of the inner wall of the casing 2 is provided with a protective net 3, the outer surface of the front end of the casing 2 is provided with a lifting rail 4, the lifting rail 4 The outer surface of the front end is provided with a movable fixed block 5, the outer surface of the front end of the movable fixed block 5 is provided with a high-strength supporting plate 6, the outer surface of the upper end of the casing 2 is provided with a protective plate 7, and the movable fixed block 5 includes a movable block 501 and a screw hole 502 , positioning holes 503 and sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com