A device, method and application for preparing monodisperse calcium alginate microspheres

A calcium alginate, monodisperse technology, applied in microsphere preparation, gel preparation, microcapsule preparation, etc., can solve problems such as removal and cleaning, and achieve the effects of sufficient reaction, good sphericity, simple and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In some typical embodiments, the preparation method of the monodisperse calcium alginate microspheres comprises the following steps:

[0040] Step 1: Put the prepared outer water phase into the outer glass tube, when the outer water phase fluid flows out of the outer glass tube outlet, put the middle oil phase into the middle phase glass tube, and when the middle oil phase flows out of the middle phase glass tube outlet, Pass the inner water phase into the inner phase glass tube;

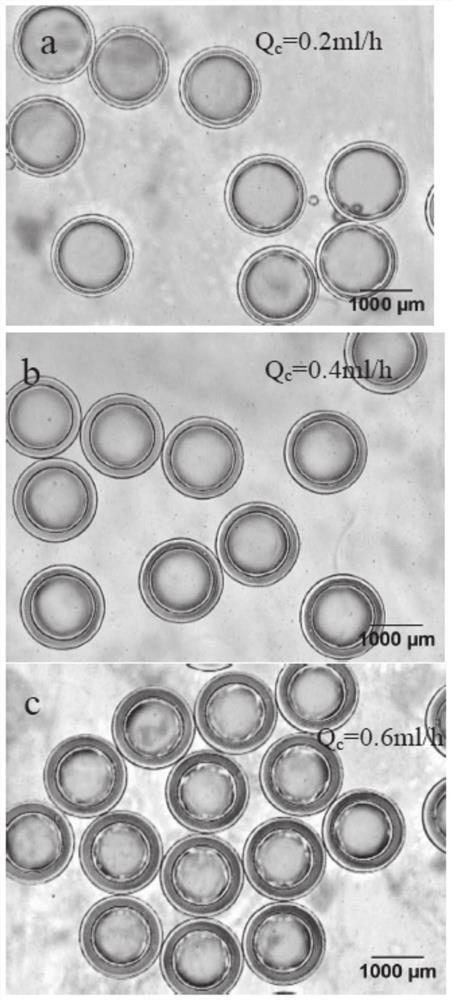

[0041] Step 2: Due to the effect of fluid shear force, the inner water phase forms a single-layer droplet covered by the intermediate oil phase at the outlet of the inner-phase glass tube, and the intermediate oil phase containing the single-layer droplet is in the middle-phase glass tube. A double-layer droplet covered by the outer water phase is formed at the outlet, and the double-layer droplet flows into the collected water phase configured in the collection petri dish along with the oute...

Embodiment 1

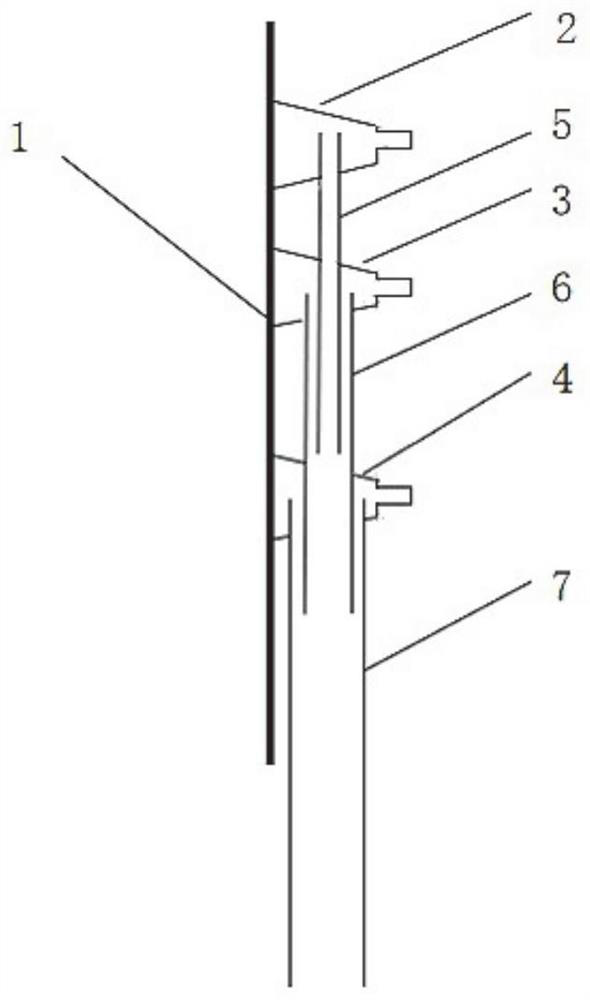

[0056] A device for preparing monodisperse calcium alginate microspheres, such as figure 1 As shown, it includes an inner phase glass tube 5, a middle phase glass tube 6 and an outer phase glass tube 7 arranged coaxially. The inner phase glass tube passes through the second dispensing needle and is inserted into the middle phase glass tube. The middle phase glass tube Insert the outer phase glass tube through the third dispensing needle, the outer phase glass tube extends into the collection culture dish, the inner phase glass tube communicates with the inner cavity of the first dispensing needle 2, and the middle phase glass tube communicates with the second point The inner space of the glue needle 3 communicates, the outer glass tube communicates with the inner space of the third glue dispensing needle 4, and the first glue dispensing needle, the second glue dispensing needle and the third glue dispensing needle are fixedly connected to the base plate.

Embodiment 2

[0058] A device for preparing monodisperse calcium alginate microspheres, the same as in Example 1, the difference is that the first dispensing needle, the second dispensing needle and the third dispensing needle are respectively connected to a syringe, and the syringe and the flow pump connected, use the flow pump to drive the respective syringes, so that the inner water phase, the middle oil phase and the outer water phase are respectively injected into the first dispensing needle, the second dispensing needle and the third dispensing needle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com