A high-temperature-resistant, halogen-free, flame-retardant and environmentally friendly cable for smart energy EMUs and its production process

A technology of smart energy and EMUs, applied in the direction of insulated cables, cable/conductor manufacturing, cables, etc., can solve problems such as poor tensile strength and wear resistance, affecting cable strength and flame retardancy, and affecting cable service life. Achieve the effects of increasing tensile performance and wear resistance, improving flame retardancy and light transmittance, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

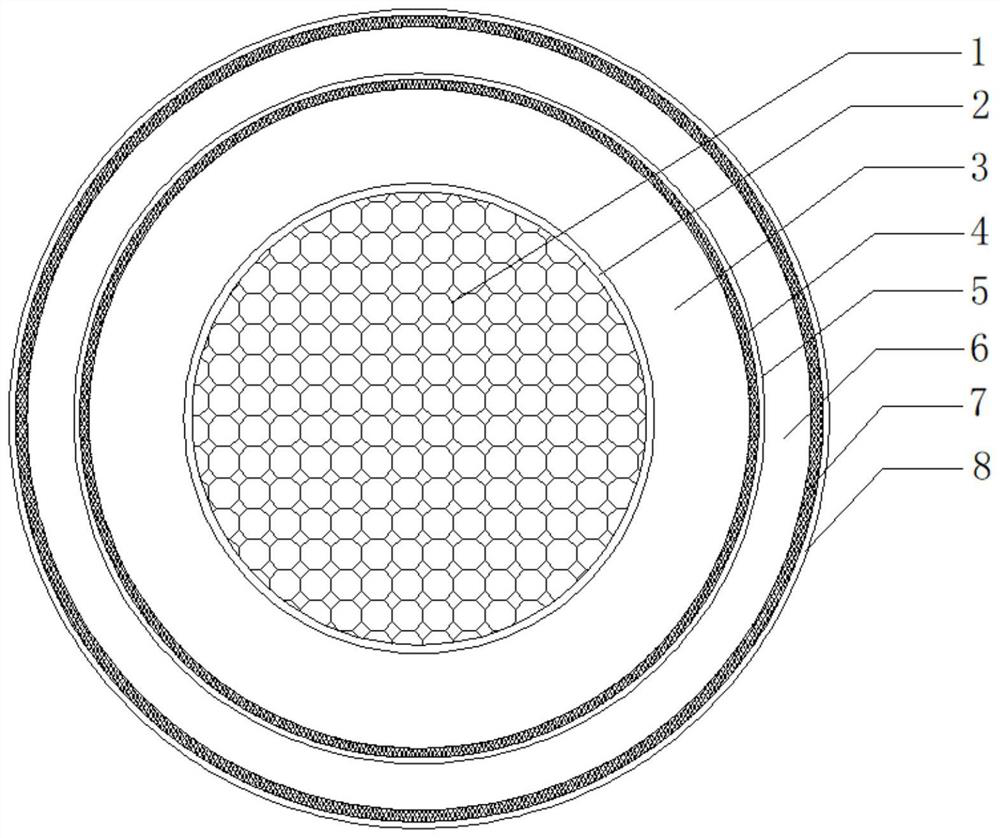

[0044] refer to figure 1 , is a high-temperature-resistant halogen-free flame-retardant environmental protection cable for smart energy EMUs disclosed in the present invention, which sequentially includes a conductor 1, a low-smoke halogen-free flame-retardant tape 2, an insulating layer 3, a fiber braided reinforcement layer 74, an inner Coating layer 5 , sheath 6 , fiberglass braid and outer coating layer 8 .

[0045] In this embodiment, the conductor 1 is a copper conductor 1 with a cross-sectional area of 4mm 2, the number of conductors is 231, the wire diameter is 0.145mm, the twisting pitch is not more than 14 times the outer diameter of the conductor 1, and the thickness of the low-smoke halogen-free flame-retardant tape 2 on the outside is 0.2mm and the width is 10mm. The covering rate is 20% to 25%; the thickness of the insulating layer 3 is 2.6m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com