Linear structured light three-phase synchronous measurement system and method based on neural network and calibration method

A line-structured light and neural network technology, applied in the field of visual measurement, can solve problems such as high cost, data distortion, internal and external parameters of the camera, and complex laser plane calibration process, and achieve the effect of avoiding complicated processes and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

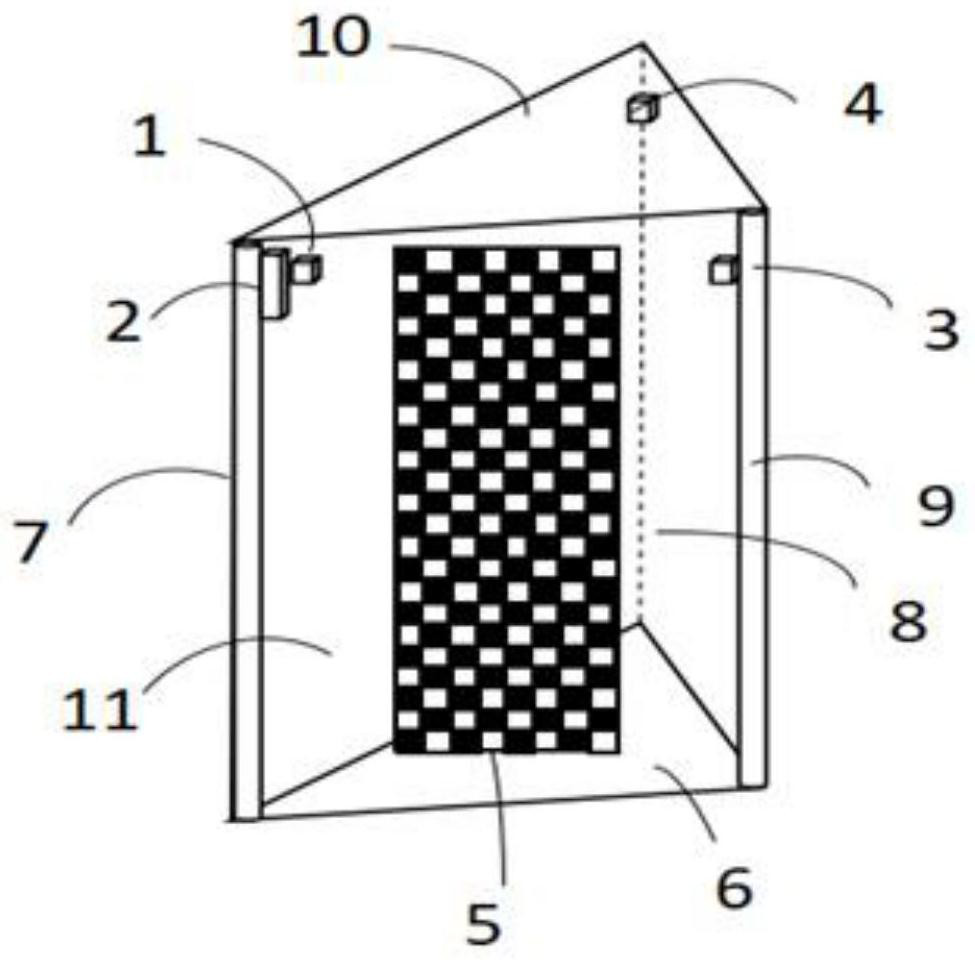

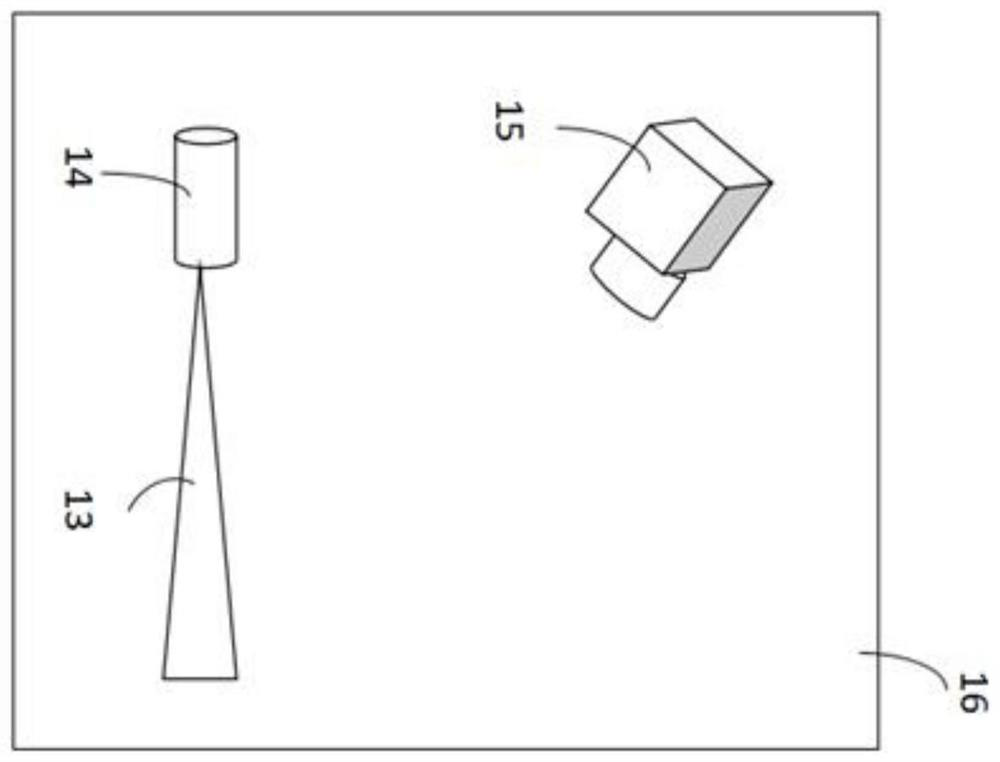

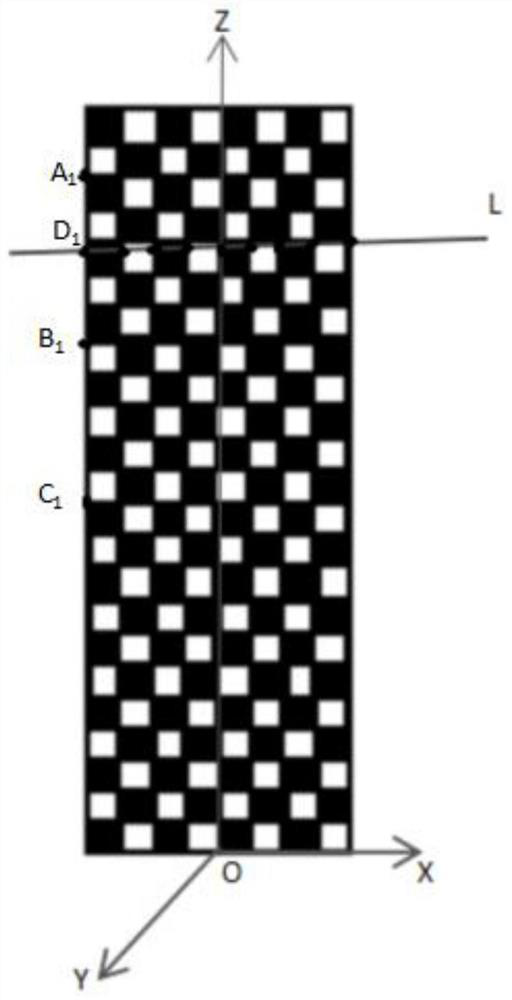

[0046] Such as figure 1 and as figure 2 As shown, a three-phase synchronous measurement system for line-structured light based on a neural network includes an installation base 6, a top baffle 10 and three side baffles, and an installation base 6, a top baffle 10 and three side baffles constitute a closed space;

[0047] The first adjustable structured light visual sensor 1, the second adjustable structured light visual sensor 3, the third adjustable structured light visual sensor 4, the magnetic head 2 and the magnetic ruler 7; the magnetic head 2 and the magnetic ruler 7 constitute a magnetic scale Displacement sensor: Magnetic ruler 7, first slide rail 8 and second slide rail 9 are vertically installed on the installation base plate 6, and the first adjustable The structured light vision sensor 1, the second adjustable structured light vision sensor 3 and the third adjustable structured light vision sensor 4, the top and the end of the ruler 7, the first slide rail 8 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com