High-integration complete machine device of microscope objective

A high-integration, microscopic objective lens technology, applied in the direction of microscopes, photo-plate-making process exposure devices, installation, etc., can solve the problems of complex structure, difficulty in application, lack of overall planning of adjustment links, etc., and achieve the effect of high optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. Those skilled in the art can also obtain other drawings based on these drawings without creative work.

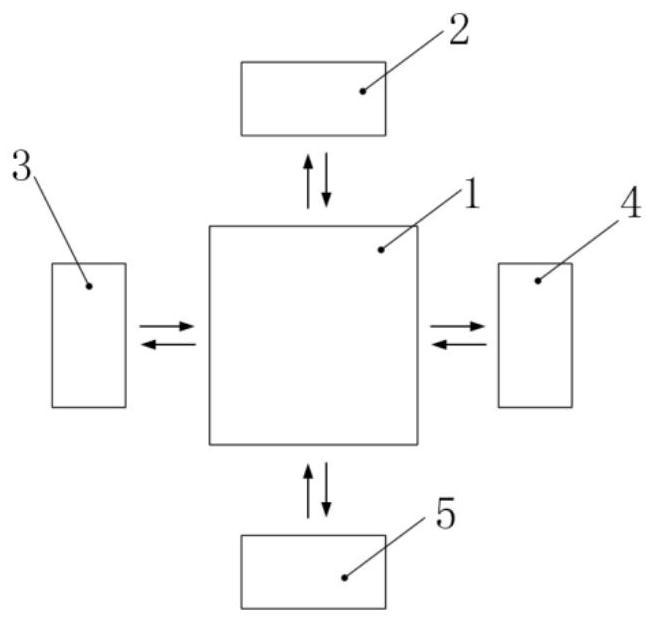

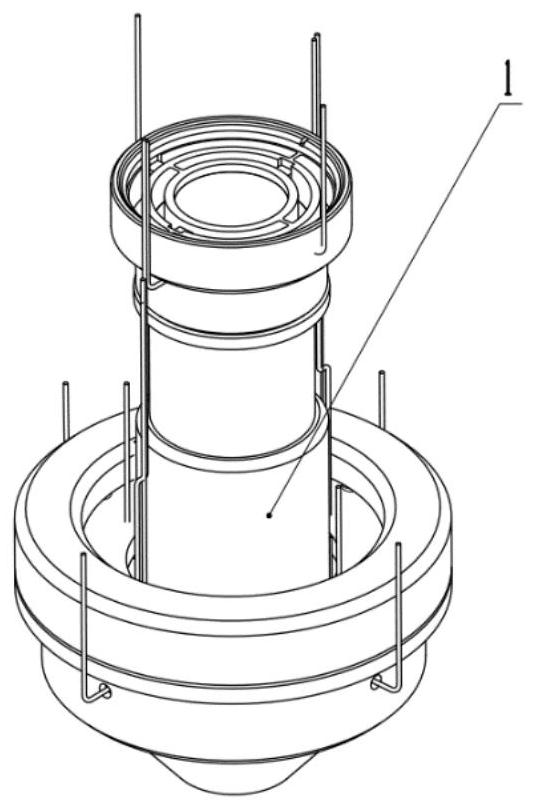

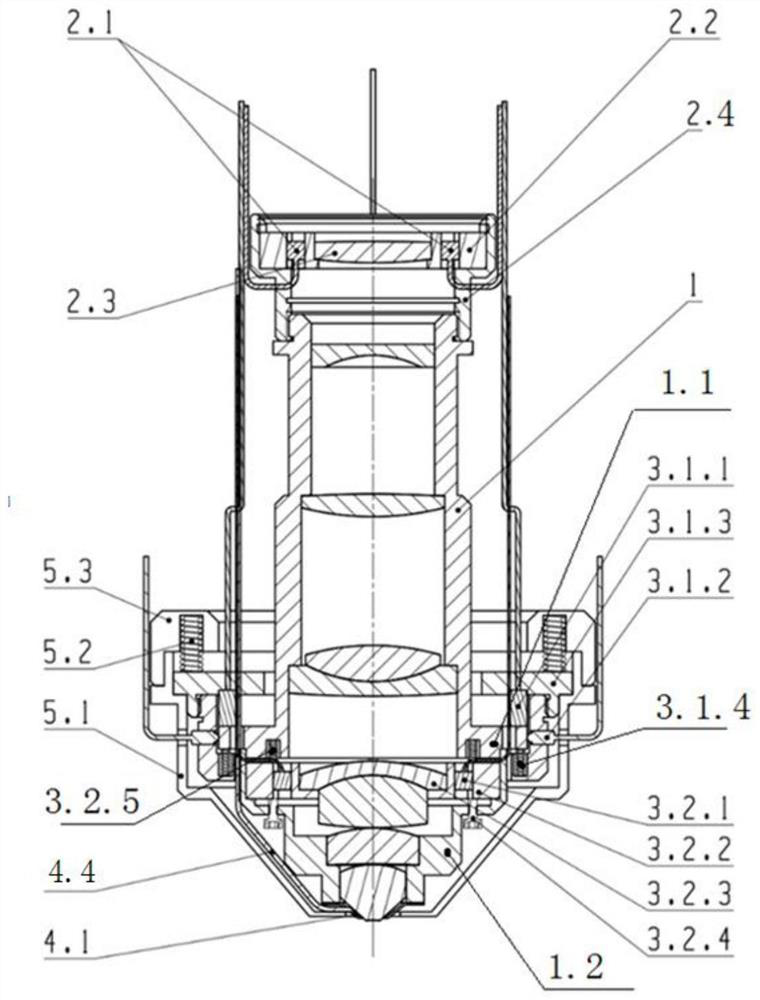

[0028] Such as figure 1 , 2 As shown, the highly integrated complete device of the microscope objective lens of the present invention includes five modules: the basic imaging objective lens main body 1, the zero position calibration device 2, the precise adjustment device 3, the immersion head assembly 4, and the objective lens anti-collision device 5.

[0029] Such as image 3 , 4As shown, the zero calibration device 2 is connected with the basic imaging objective lens main body 1 through scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com