Electrochemical sensor for detecting nitrite, preparation method and application

A nitrite and sensor technology, applied in the field of electrochemical analysis, can solve problems such as poor conductivity, and achieve the effects of easy control of the process, overcoming time-consuming, and high specific recognition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

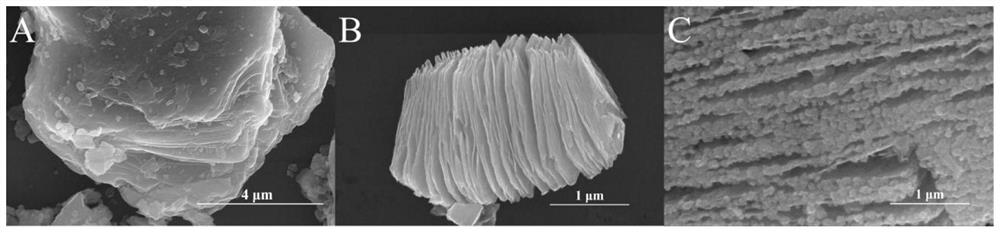

Image

Examples

Embodiment 1

[0029] Preparation of sensors

[0030] ① Slowly add 1.0g aluminum carbon titanium oxide to 20mL 40wt% hydrogen fluoride, carry out stirring etching at 40°C for 24 hours, centrifuge the product after the reaction is completed, until the pH value of the supernatant is between 5 and 6, filter, Dry under vacuum at 80°C for 24 hours to obtain titanium carbide;

[0031] ②Using titanium carbide as the titanium source, titanium carbide is calcined in two stages, the first stage is calcined in air at 200°C for 1 hour, the second stage is calcined in nitrogen at 500°C for 1 hour, and the temperature is naturally cooled to obtain titanium dioxide-titanium carbide Complex;

[0032] ③ Disperse the titanium dioxide-titanium carbide compound in a solution containing cetyltrimethylammonium bromide and chitosan, and obtain titanium dioxide-titanium carbide / cetyltrimethylammonium bromide through ultrasonic dispersion / chitosan dispersion, wherein the concentration of titanium dioxide-titanium...

Embodiment 2

[0038] Preparation of sensors

[0039] ① Slowly add 0.8g aluminum carbon titanium oxide to 20mL 40wt% hydrogen fluoride, carry out stirring etching at 30°C for 48 hours, centrifuge the product after the reaction is completed, until the pH value of the supernatant is between 5 and 6, filter, Dry under vacuum at 80°C for 24 hours to obtain titanium carbide;

[0040] ②Using titanium carbide as the titanium source, titanium carbide is calcined in two stages, the first stage is calcined in the air at 200°C for 0.5h, the second stage is calcined in nitrogen at 500°C for 2h, and the temperature is naturally cooled to obtain titanium dioxide-carbide Titanium complex;

[0041] ③ Disperse the titanium dioxide-titanium carbide compound in a solution containing cetyltrimethylammonium bromide and chitosan, and obtain titanium dioxide-titanium carbide / cetyltrimethylammonium bromide through ultrasonic dispersion / chitosan dispersion, wherein, the concentration of titanium dioxide-titanium ...

Embodiment 3

[0046] Preparation of sensors

[0047] ① Slowly add 1.2g aluminum carbon titanium oxide to 20mL 40wt% hydrogen fluoride, carry out stirring etching at 50°C for 6 hours, centrifuge the product after the reaction is completed, until the pH value of the supernatant is between 5 and 6, filter, Dry under vacuum at 80°C for 24 hours to obtain titanium carbide;

[0048] ②Using titanium carbide as the titanium source, titanium carbide is calcined in two stages, the first stage is calcined in air at 200°C for 2 hours, the second stage is calcined in nitrogen at 500°C for 1 hour, and the temperature is naturally cooled to obtain titanium dioxide-titanium carbide Complex;

[0049] ③ Disperse the titanium dioxide-titanium carbide compound in a solution containing cetyltrimethylammonium bromide and chitosan, and obtain titanium dioxide-titanium carbide / cetyltrimethylammonium bromide through ultrasonic dispersion / chitosan dispersion, wherein, the concentration of titanium dioxide-titaniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com