Heating furnace with oxygen blowing mechanism for steel casting

A heating furnace and steel technology, applied in the field of steel casting, can solve the problems of inability to meet demand, waste of resources, potential safety hazards, etc., and achieve the effect of improving the spread breadth and distribution range, improving the effect of oxygen blowing, and realizing effective utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

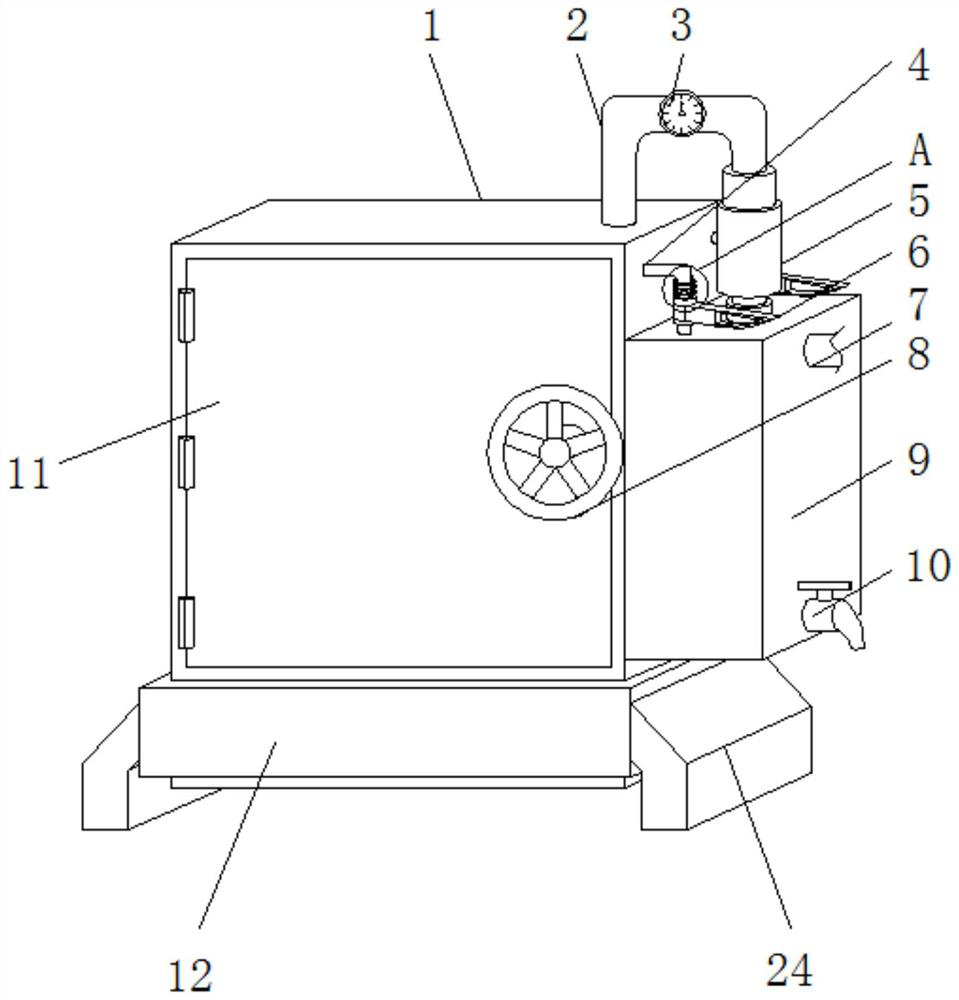

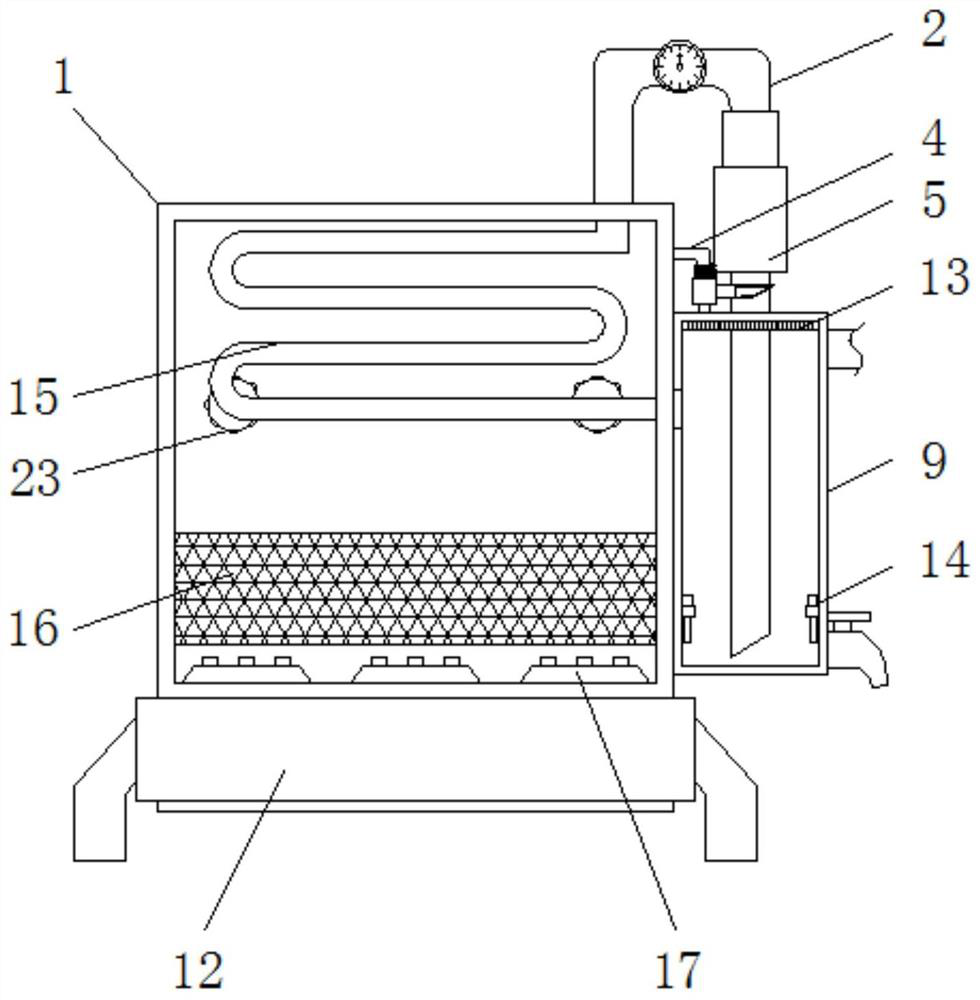

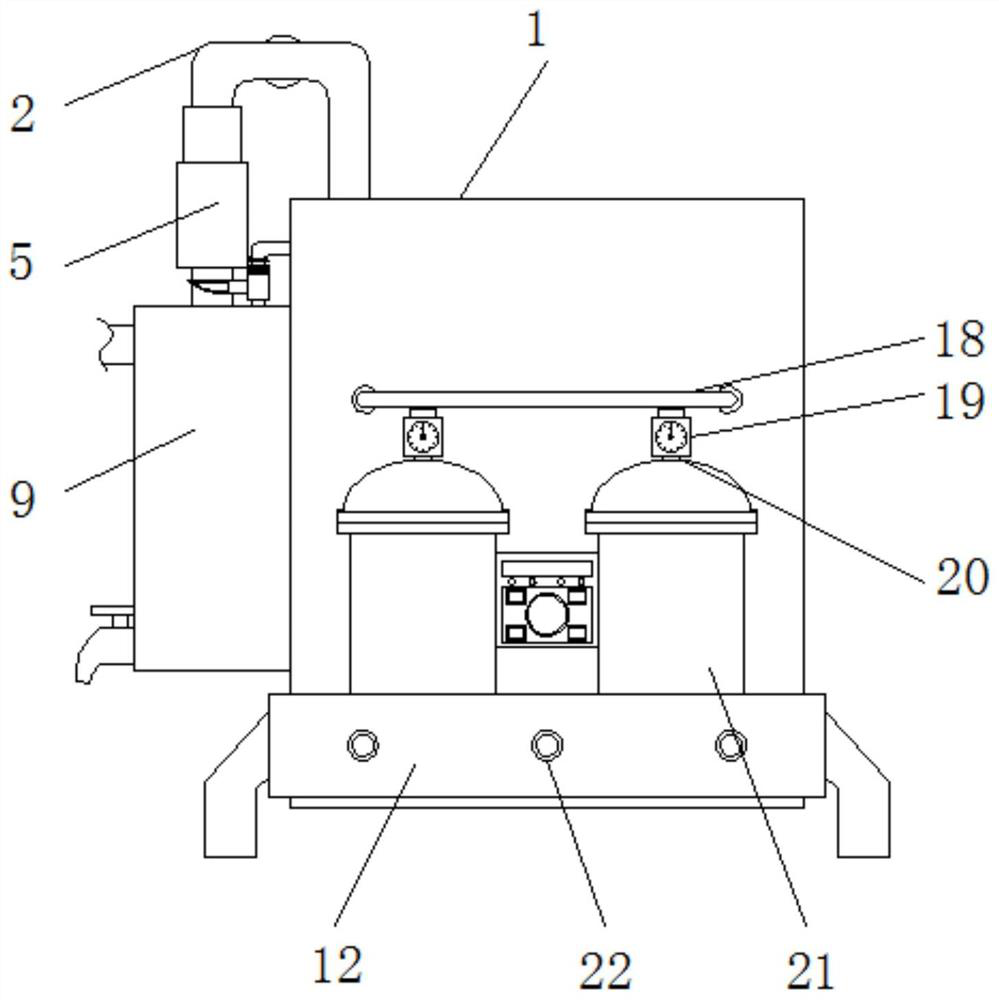

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0033] Such as Figure 1-8 As shown, the embodiment provides a heating furnace with an oxygen blowing mechanism based on steel casting, including a heating furnace main body 1, a gas control mechanism 6, a heat collection water tank 9, an explosion-proof door 11, a U-shaped water pipe 15, and a burner 17. Oxygen generator 21 and oxygen blowing mechanism 23. An explosion-proof door 11 is installed on the outside of the heating furnace main body 1 through hinges. A base 12 is fixedly installed on the bottom of the heating furnace main body 1. The heat collection water tank 9 is fixed Installed on the outer wall of one side of the heating furnace main body 1, a water guide pipe 2 is installed between the heating furnace main body 1 and the heat collection water tank 9, and one end of the water guide pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com