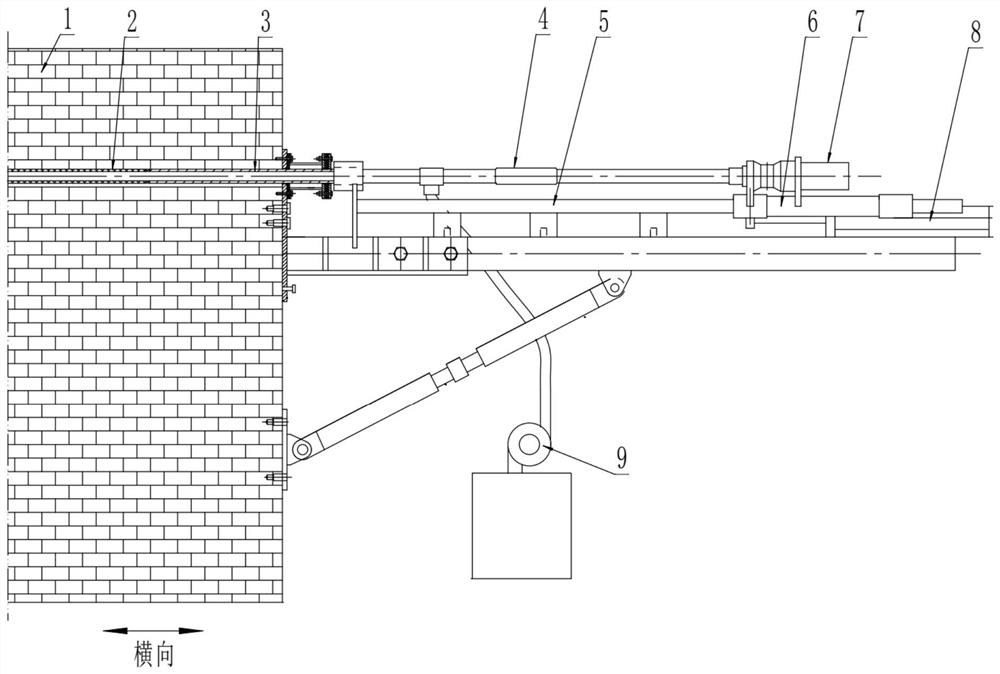

A kind of horizontal repair hole wall protection method of house wall

A technology of transverse holes and walls, which is applied in the direction of building maintenance, construction, building construction, etc., can solve the problems affecting the effect of grouting and anchoring of steel tie rods, the surface of the built-in walls of houses is defaced, and the strength of transverse holes is insufficient. Achieve good adhesion, improve repair strength, and improve strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, take by weighing 46Kg of washed sand with a particle size of 100 mesh, 39Kg of Portland cement, 3.6Kg of slaked lime powder, 0.25Kg of wood fiber, 0.5Kg of polyacrylamide, 0.08Kg of defoamer, 0.12Kg of cellulose ether, stearin Calcium acid 0.056Kg, talcum powder 5Kg, polycarboxylate superplasticizer 0.04Kg, layered silicate 0.2Kg, silicon micropowder 0.8Kg, magnesium aluminum silicate 1.1Kg, calcium oxide-calcium sulfate composite expansion agent 1.4Kg, weight Crystal powder 0.7Kg. Add the above-mentioned raw materials according to the mass ratio of raw materials: water of 100:24, add water and fully stir evenly to prepare wall protection slurry.

Embodiment 2

[0025] Embodiment 2, weighing 48Kg of washed sand with a particle size of 80 meshes, 38Kg of Portland cement, 3.7Kg of slaked lime powder, 0.2Kg of wood fiber, 0.45Kg of polyacrylamide, 0.07Kg of defoamer, 0.11Kg of cellulose ether, stearin Calcium acid 0.06Kg, talc powder 5.2Kg, polycarboxylate superplasticizer 0.04Kg, layered silicate 0.22Kg, silicon micropowder 0.9Kg, magnesium aluminum silicate 1.2Kg, calcium oxide-calcium sulfate composite expansion agent 1.6Kg, Barite powder 0.5Kg. Add the above-mentioned raw materials according to the mass ratio of raw materials: water of 100:23, add water and fully stir evenly to prepare wall protection slurry.

Embodiment 3

[0026]Embodiment 3, weighing 47Kg of washed sand with a particle size of 140 meshes, 40Kg of Portland cement, 4.0Kg of slaked lime powder, 0.3Kg of wood fiber, 0.4Kg of polyacrylamide, 0.09Kg of defoamer, 0.13Kg of cellulose ether, stearin Calcium acid 0.05Kg, talc powder 5.4Kg, polycarboxylate superplasticizer 0.04Kg, layered silicate 0.21Kg, silicon micropowder 1Kg, magnesium aluminum silicate 1.3Kg, calcium oxide-calcium sulfate composite expansion agent 1.5Kg, weight Crystal powder 0.6Kg. Add the above-mentioned raw materials according to the mass ratio of raw materials: water of 100:25, add water and fully stir evenly to prepare wall protection slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com