Eco-solvent smooth and transparent leather treatment agent and preparation method thereof

A technology of leather treatment agent and weak solvent, which is applied in the field of weak solvent cotton slippery and translucent leather treatment agent and its preparation, can solve the problems of increased cost, insufficient oily wax, etc., achieve good oiliness, solve insufficient brightness, and improve brightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

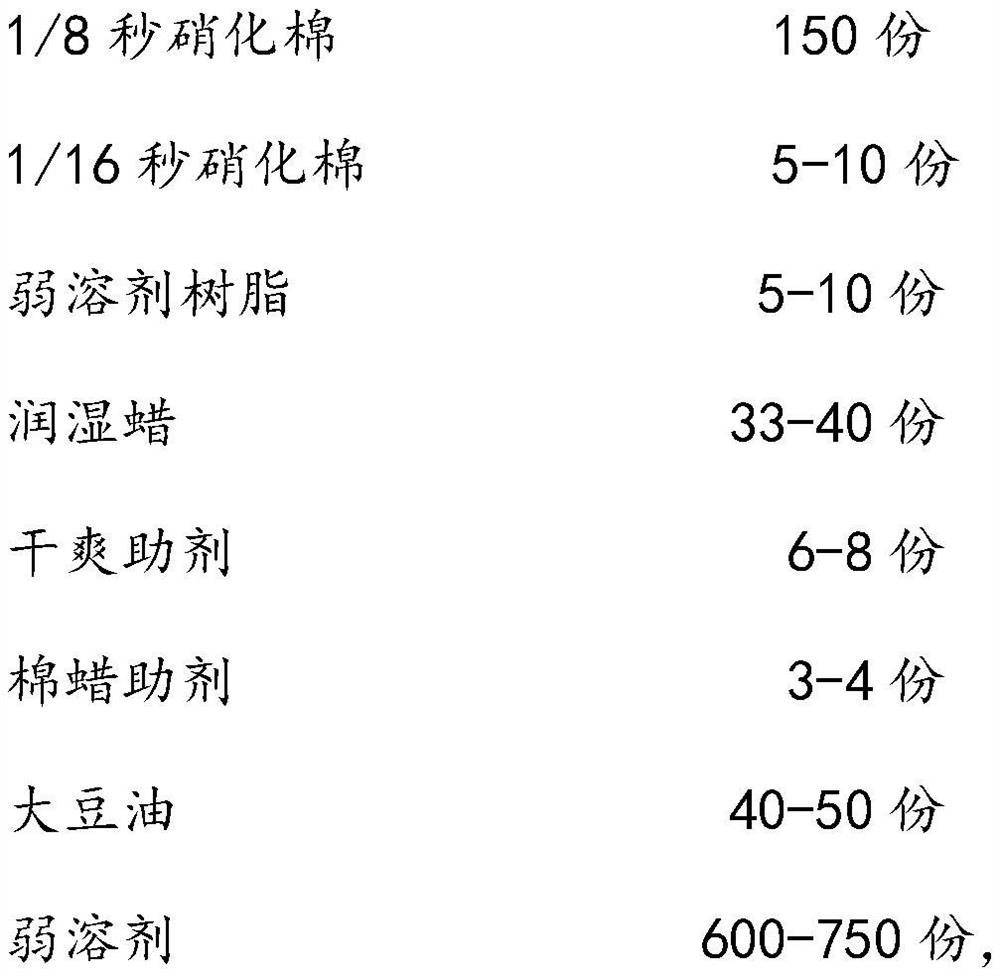

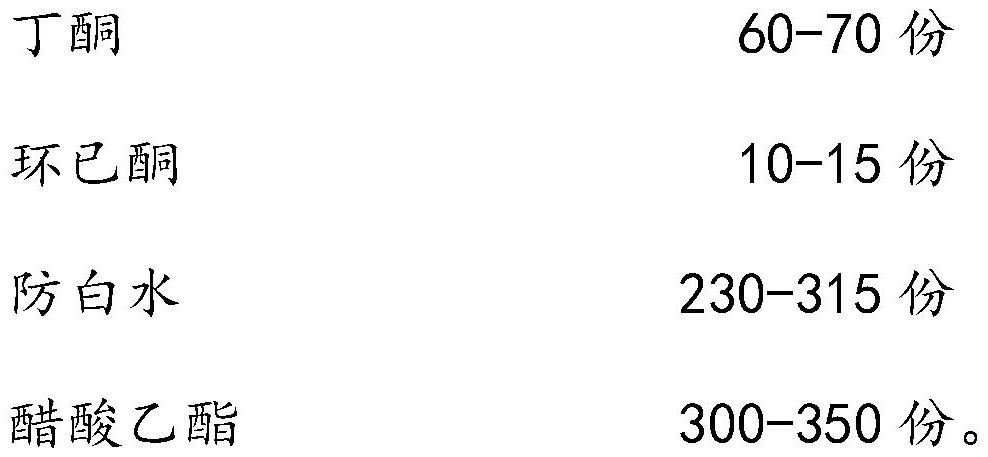

[0030] A weak solvent cotton slippery translucent leather treatment agent is characterized in that, according to parts by weight, it includes the following raw materials: 150 parts of 1 / 8 second nitrocellulose, 7 parts of 1 / 16 nitrocellulose, 7 parts of weak solvent resin, moistening 37 parts of wet wax, 7 parts of dry auxiliary agent, 3.5 parts of cotton wax auxiliary agent, 46 parts of soybean oil, 65 parts of butanone, 12 parts of cyclohexanone, 300 parts of anti-white water, 320 parts of ethyl acetate.

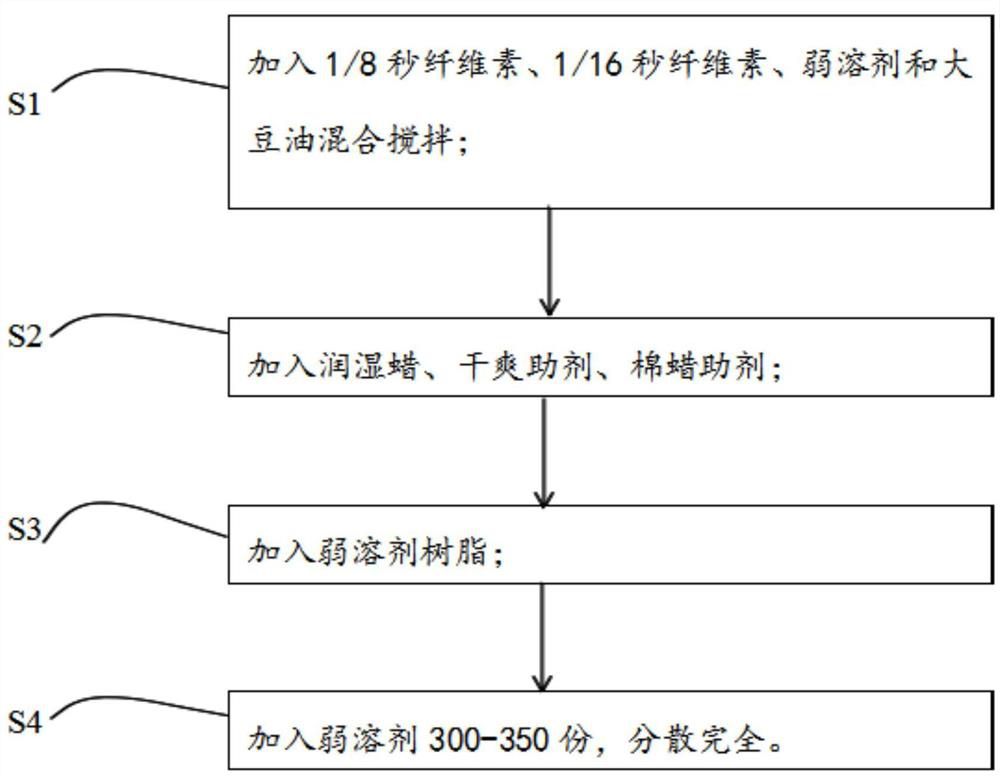

[0031] A kind of technical scheme is to provide the preparation method of weak solvent cotton slippery translucent leather treatment agent, it is characterized in that, comprises the following steps:

[0032] S1: mixing and stirring of 1 / 8 second nitrocellulose, 1 / 16 second nitrocellulose, weak solvent and soybean oil;

[0033] S2: Stir and add wetting wax, drying additive, cotton wax additive;

[0034] S3: add weak solvent resin;

[0035] S4: Add a weak solvent and disp...

Embodiment 2

[0038] This embodiment provides a weak solvent cotton slippery translucent leather treatment agent component and a preparation method thereof, the steps are the same as those in Example 1, and the components are different in that:

[0039] 5 parts of 1 / 8 nitrocellulose, 5 parts of weak solvent resin, 33 parts of wetting wax, 6 parts of drying additive, 3 parts of cotton wax additive, 40 parts of soybean oil, 60 parts of butanone, 10 parts of cyclohexanone, 230 parts of white water, 300 parts of ethyl acetate.

Embodiment 3

[0041] This embodiment provides a weak solvent cotton slippery translucent leather treatment agent component and a preparation method thereof, the steps are the same as those in Example 1, and the components are different in that:

[0042] 10 parts of 1 / 8 nitrocellulose, 10 parts of weak solvent resin, 40 parts of wetting wax, 8 parts of drying additive, 4 parts of cotton wax additive, 50 parts of soybean oil, 70 parts of butanone, 15 parts of cyclohexanone, 310 parts of white water, 350 parts of ethyl acetate.

[0043] The weak solvent smooth and translucent treatment agents prepared in the above three examples can solve the problems of side white light and oily waxy light in the surface treatment of high-grade leather products without increasing the cost, so as to meet the needs of market development and open up new markets.

[0044] Explanation: The carrier resin modulus of the weak solvent treatment agent is lower than that of the strong solvent treatment agent, so it has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com