Plastic material based on high-wear-resistance water-based elastic coating

An elastic coating, water-based technology, applied in the field of composite plastics, can solve the problems of unbalanced wear resistance and hand feeling, good hand feel, poor wear resistance, good wear resistance and hard hand feeling, etc. The effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

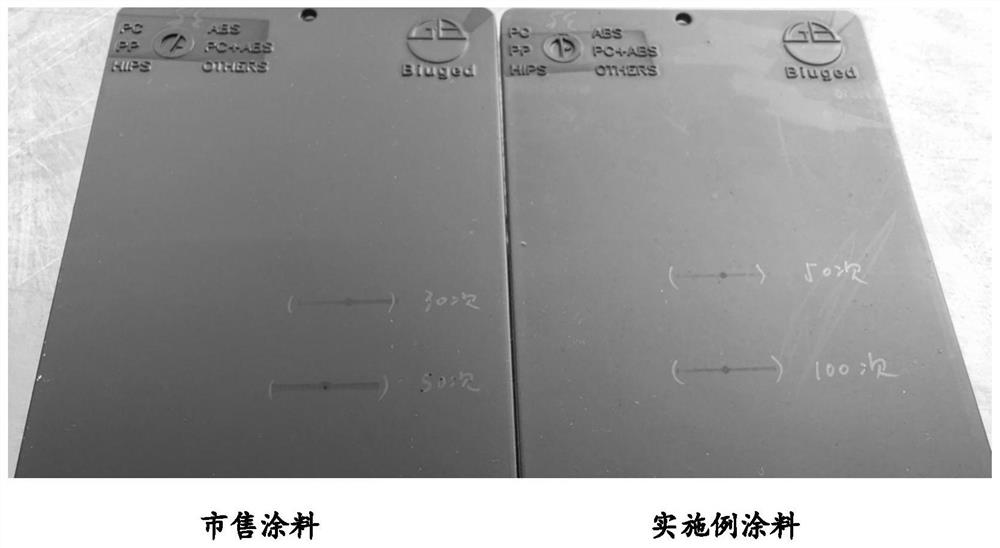

Image

Examples

Embodiment 1

[0023] A high wear-resistant water-based elastic coating, which is prepared by stirring and mixing Agent A and Agent B at a weight ratio of 10:2. Agent A is composed of the following components: water-based polycarbonate polyurethane, water-based polyether polyurethane, water-based hydroxyacrylic acid, neutralizer, water-based dispersant, water-based wetting and leveling agent, water-based defoamer, water-based thixotropic agent, Water-based wax paste, deionized water.

[0024] Agent A (100 parts by weight) basic formula is as follows:

[0025]

[0026] B agent is mixed by curing agent and diluent; B agent (100 parts by weight) basic formula is as follows:

[0027] Curing agent Bayer 304 85 parts

[0028] Propylene glycol methyl ether acetate 15 parts

[0029] 1. Add the above-mentioned water-based polycarbonate polyurethane, water-based polyether polyurethane, water-based hydroxyacrylic acid and other water-based resins into the dispersion tank in proportion, and disperse...

Embodiment 2

[0042] A high wear-resistant water-based elastic coating, which is prepared by stirring and mixing agent A and agent B at a weight ratio of 10:3. Agent A is composed of the following components: water-based polycarbonate polyurethane, water-based polyether polyurethane, water-based hydroxyacrylic acid, neutralizer, water-based dispersant, water-based wetting and leveling agent, water-based defoamer, water-based thixotropic agent, Water-based wax paste, deionized water.

[0043] Agent A (100 parts by weight) basic formula is as follows:

[0044]

[0045] B agent is mixed by curing agent and diluent; B agent (100 parts by weight) basic formula is as follows:

[0046] Curing agent Bayer 304 85 parts

[0047] Propylene glycol methyl ether acetate 15 parts

[0048] 1. Add the above-mentioned water-based polycarbonate polyurethane, water-based polyether polyurethane, water-based hydroxyacrylic acid and other water-based resins into the dispersion tank in proportion, and disper...

Embodiment 3

[0055] A high wear-resistant water-based elastic coating, which is prepared by stirring and mixing Agent A and Agent B at a weight ratio of 10:2. Agent A is composed of the following components: water-based polycarbonate polyurethane, water-based polyether polyurethane, water-based hydroxyacrylic acid, neutralizer, water-based dispersant, water-based wetting and leveling agent, water-based defoamer, water-based thixotropic agent, Water-based wax paste, deionized water.

[0056] Agent A (100 parts by weight) basic formula is as follows:

[0057]

[0058] B agent is mixed by curing agent and diluent; B agent (100 parts by weight) basic formula is as follows:

[0059] Curing agent Bayer 304 85 parts

[0060] Propylene glycol methyl ether acetate 15 parts

[0061] 1. Add the above-mentioned water-based polycarbonate polyurethane, water-based polyether polyurethane, water-based hydroxyacrylic acid and other water-based resins into the dispersion tank in proportion, and disper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com