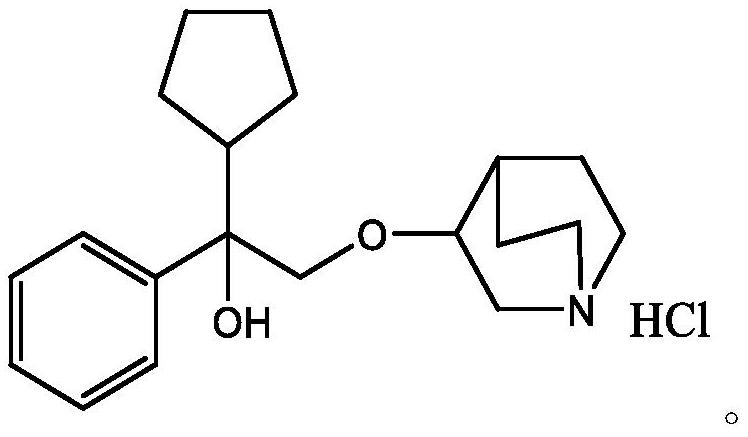

A kind of penehyclidine hydrochloride impurity and preparation method thereof

A kind of penehyclidine and impurity technology is applied in the field of penehyclidine hydrochloride impurity and preparation thereof, can solve the problems such as no literature report in the compound preparation method, and achieves the effects of low cost, good economic value and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

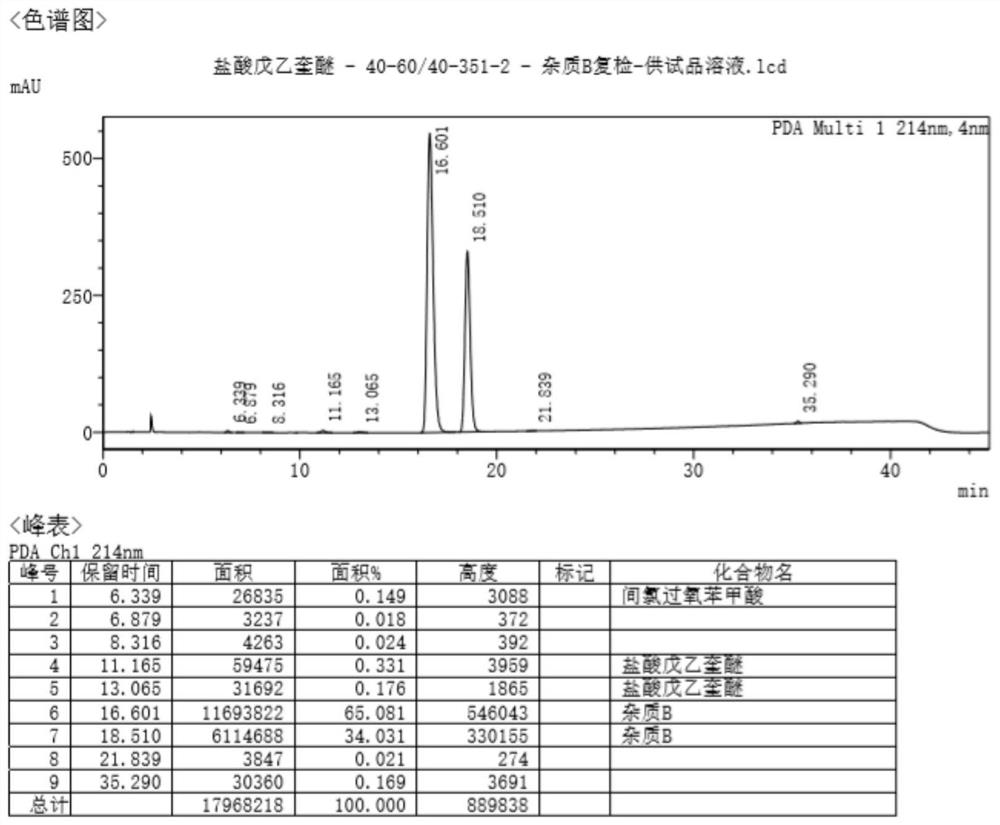

[0037] Example 1 Penehyclidine base preparation:

[0038] In a 250ml beaker, add 20g penehyclidine hydrochloride, 50ml 10% NaOH solution, 100ml ethyl acetate and stir to clarify, let stand for separation, the aqueous phase is extracted twice with ethyl acetate (200ml / time), the organic phases are combined and saturated Washed with brine, dried over anhydrous magnesium sulfate, and concentrated to dryness to give a colorless oil.

Embodiment 2

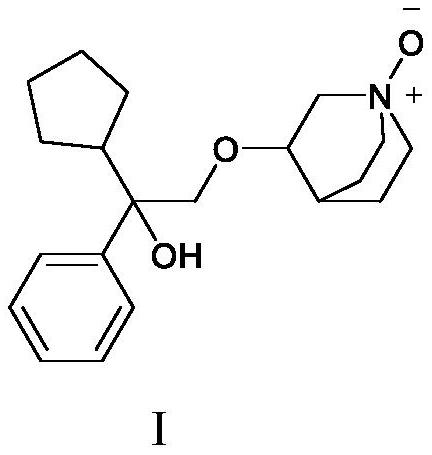

[0039] Embodiment 2: the preparation method of compound shown in formula I

[0040] All the oily substances prepared in Example 1, 300 ml of THF were added to the 500 reaction flask, stirred to dissolve, 15.7 g of m-chloroperoxybenzoic acid was added in batches, the addition was completed, and the mixture was stirred at room temperature for 36 hours.

[0041] 200ml of saturated sodium carbonate solution was added to the reaction solution, adjusted to pH 8-9, left to stand for layers, the aqueous phase was extracted twice with tetrahydrofuran (200ml / time), the organic phases were combined, dried over anhydrous magnesium sulfate, and concentrated to dryness. 15.3 g of yellow oil was obtained.

[0042] The crude product was dissolved in 100 ml of tetrahydrofuran, 15.3 g of neutral aluminum oxide (200-300 mesh) was added, and concentrated to dryness under reduced pressure, and the sample was used for later use. In addition, 153g of neutral aluminum oxide (200-300 mesh) was added ...

Embodiment 3

[0045] The preparation method of compound shown in embodiment 3 formula I

[0046] (1) All the oils prepared in Example 1 and 300 ml of THF were added to 500 reaction flasks, stirred to dissolve, 15.7 g of m-chloroperoxybenzoic acid was added in batches, and the mixture was stirred at room temperature for 28 hours.

[0047](2) 200ml of saturated sodium carbonate solution was added to the reaction solution, adjusted to pH 8-9, left to stand for stratification, the aqueous phase was extracted twice with tetrahydrofuran (200ml / time), the organic phases were combined and dried over anhydrous magnesium sulfate , concentrated to dryness to obtain 16.0g of yellow oil.

[0048] (3) Dissolve the crude product with 100 ml of tetrahydrofuran, add 32 g of neutral aluminum oxide (200-300 mesh), concentrate to dryness under reduced pressure, and use the sample for later use. In addition, 320g of neutral aluminum oxide (200-300 mesh) was added to 2L of ethyl acetate. After stirring evenly, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com