Internal polyhedron manufacturing method based on punching and cutting process

A manufacturing method and polyhedron technology, applied in the field of punching manufacturing, can solve the problems of impact of semi-finished parts, deformation of matrix, waste of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

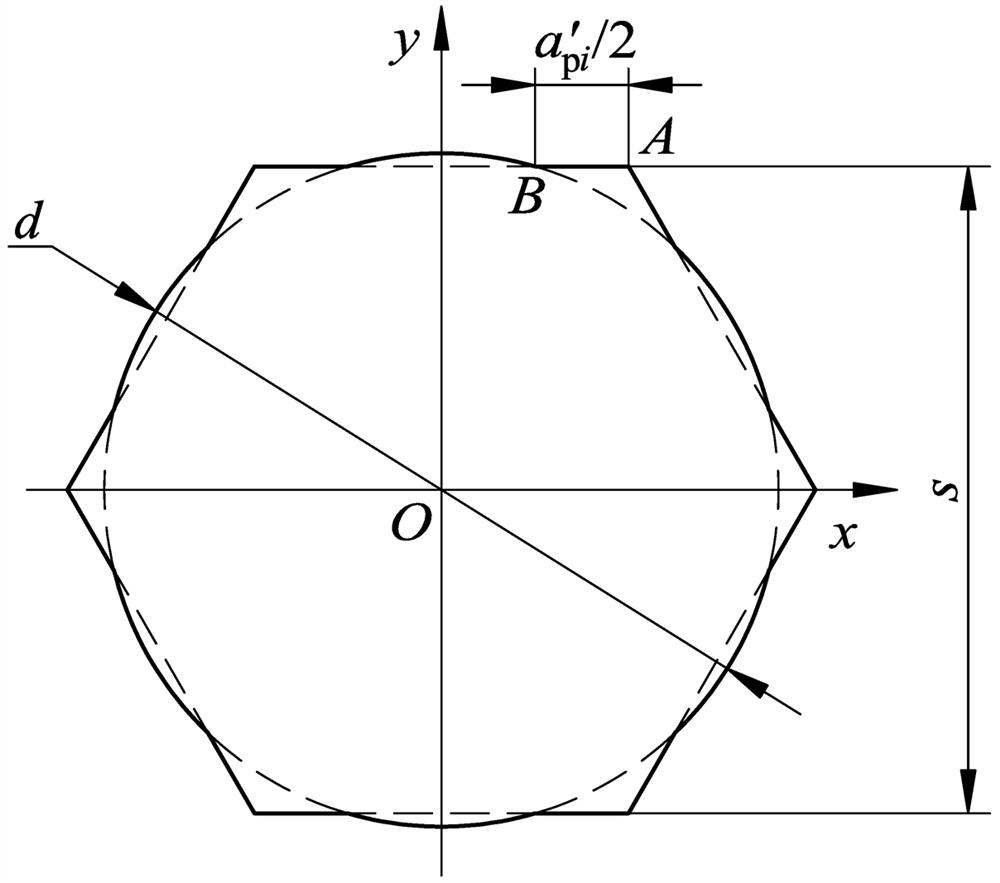

[0083] see Figure 1 to Figure 10 The regular hexahedron blanking manufacturing method, the specific steps are as follows:

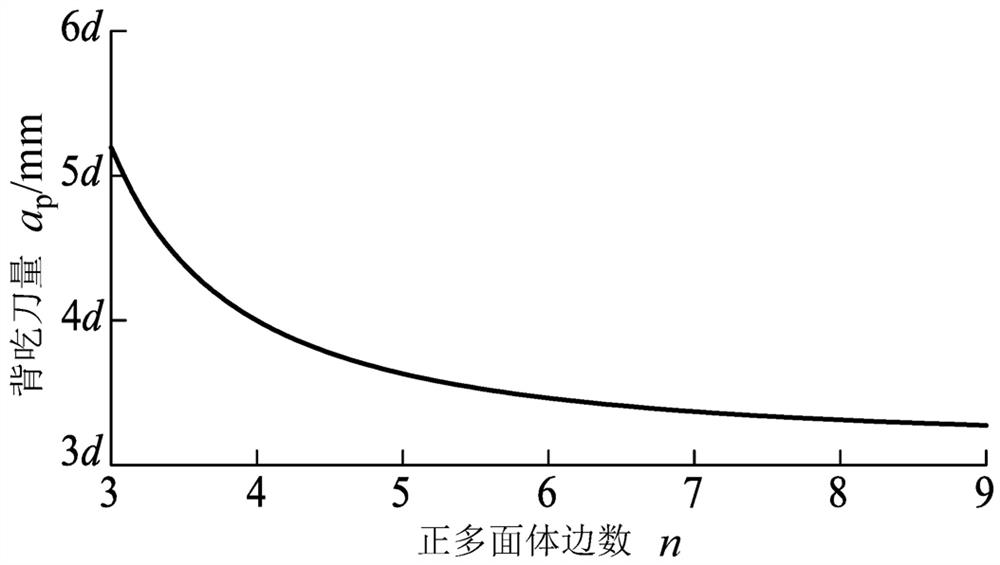

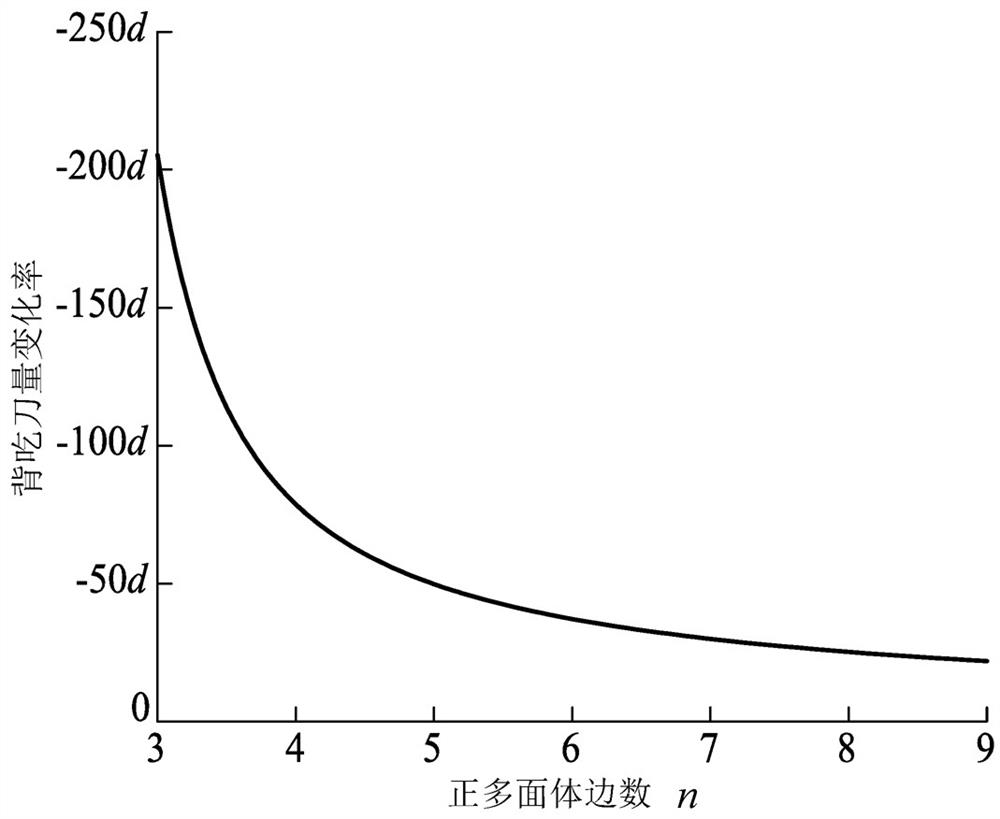

[0084] 1. Determine the optimal value of the polyhedron edge number based on the punching process for the inner polyhedron manufacturing method

[0085] Conventional internal polyhedrons for rotational torque transmission include regular trihedrons, cubes, and regular hexahedrons, as well as other common flower-shaped polyhedrons. Regular polyhedrons are mostly used for non-standard parts. For the same regular polyhedron tangent circle, the number of sides of the polyhedron is different, and the corresponding back cutting amount is also different, that is, the side length of the polyhedron changes with the number of sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com