Novel high-efficiency wall-flow-free structured silk screen filler

A technology of wire mesh packing and structured packing, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve problems affecting normal production, affecting packing efficiency, and easy accumulation, etc. Achieve the effects of increasing the liquid film renewal rate, avoiding severe turbulent flow phenomena, and avoiding wall flow phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

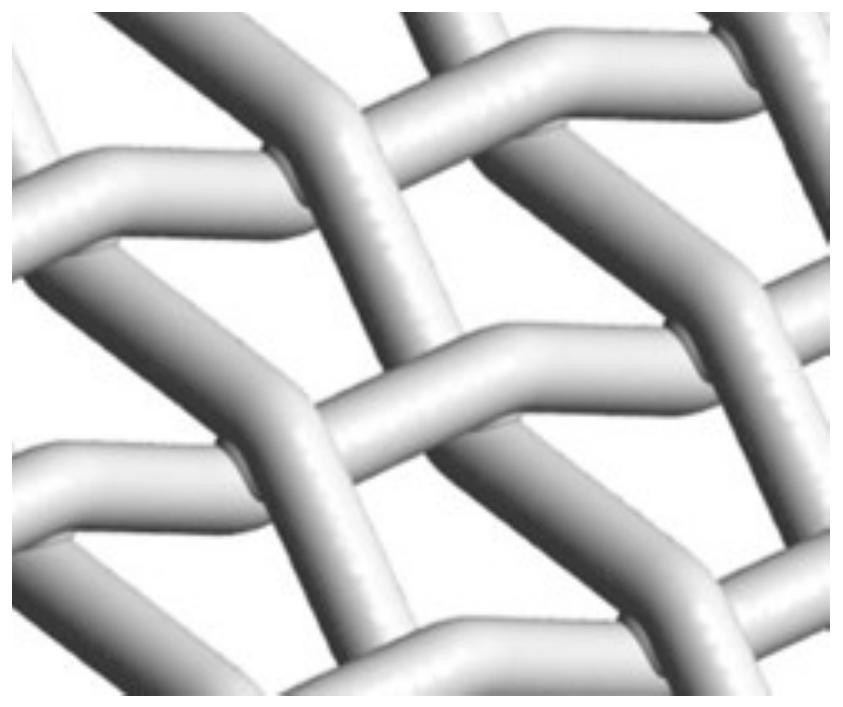

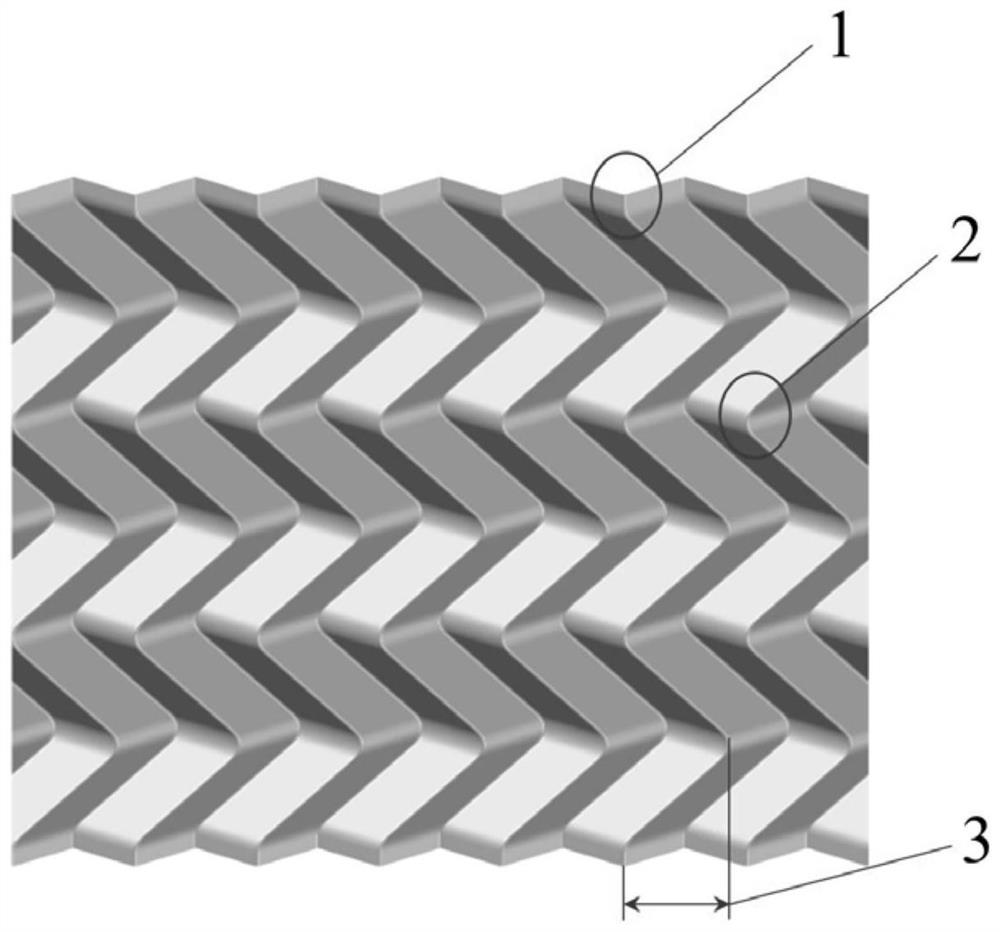

[0033] Such as figure 1 As shown, metal wires are woven into wire mesh corrugated sheets, and passivation treatment is carried out at the joints of metal systems to avoid sharp angles at the contact points of metal wires, resulting in liquid phase retention and aggregation. figure 2 As shown in Structure 3, the wire mesh is pressed into wire mesh corrugations by mold pressing method, which is different from the traditional oblique linear corrugations, and the present invention is designed as zigzag corrugations. Such as figure 2 As shown, the present invention performs a 3-5mm arc transition on the upper and lower ends of the folded line channel of the wire mesh corrugated sheet, and extends upwards by 1-5mm, so that the flow channels of the two adjacent structured packing layers are smoothly and smoothly connected. , reducing flow resistance and flow cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com