On-load tap-changer mechanical fault diagnosis method

A technology of on-load tapping and mechanical failure, applied in the field of power equipment, can solve problems such as excessive calculation, failure characteristics cannot be included in single-channel signals, and modal aliasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below through specific embodiments.

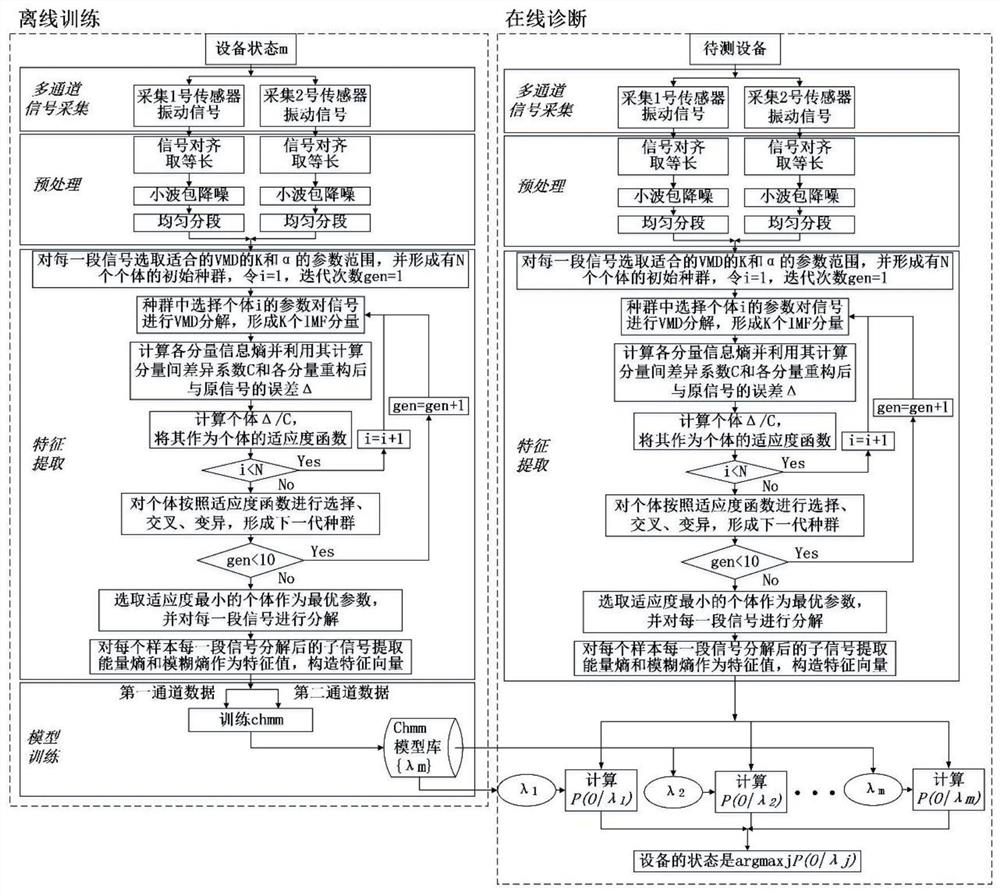

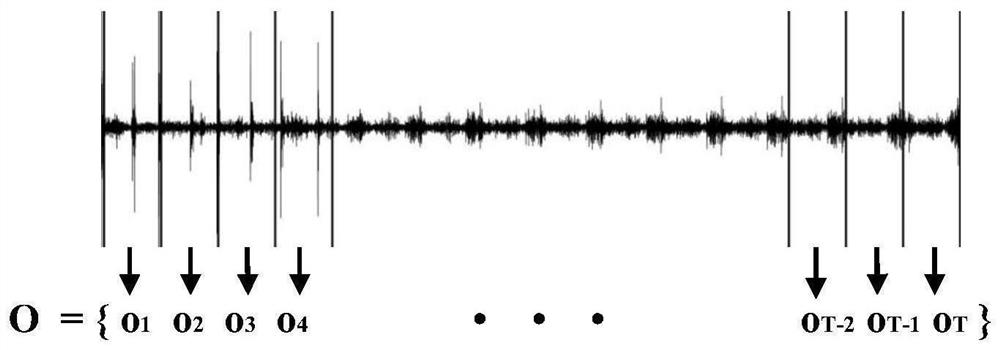

[0069] as attached figure 1 As shown, the present invention discloses a method for diagnosing mechanical faults of on-load tap-changers based on GA-VMD and multi-channel vibration signal feature fusion. The identification method includes the following steps:

[0070] Step 1: Collect the vibration signals of the normal state and the fault state of the OLTC device at no less than two positions through the acceleration sensor, and perform preprocessing;

[0071] The two acceleration sensors are adsorbed by permanent magnets on the side of the blasting cover on the OLTC head cover and on the side of the head flange close to the blasting cover. This installation method is simple and easy, and the signal picked up is less attenuated and the signal is more complete;

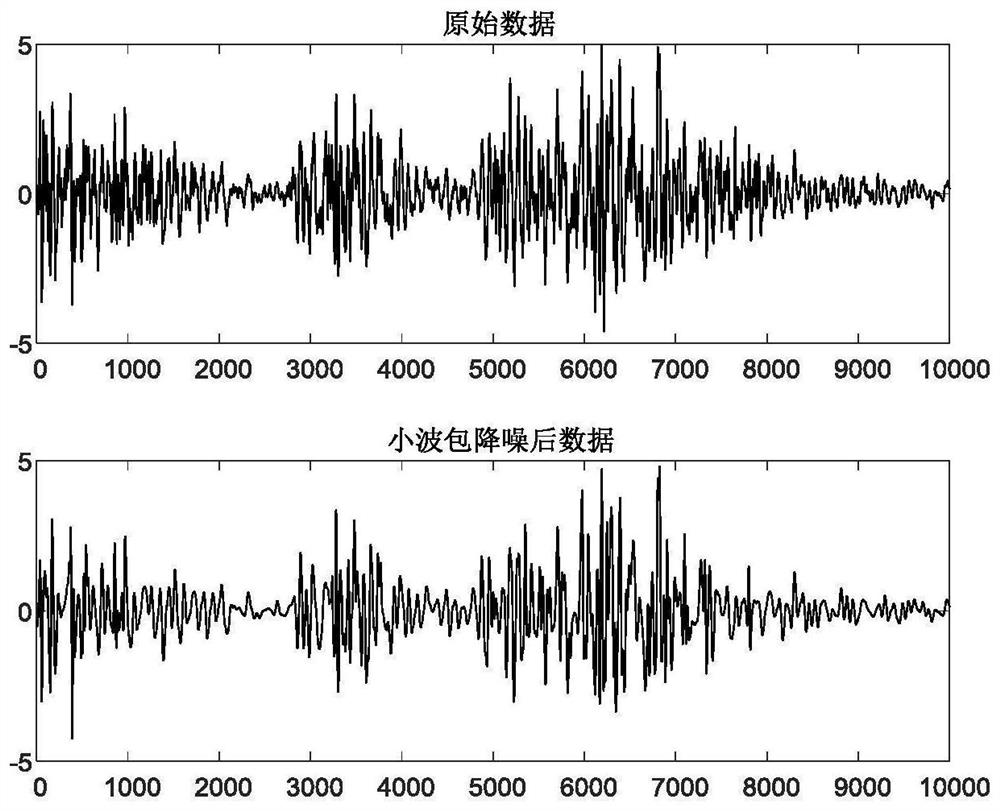

[0072] The vibration signal is preprocessed, specifically, the vibration signal is aligned, the same length is intercepted, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com