Industrial waste gas heat recovery device

A technology of heat recovery device and industrial waste gas, which is applied in the direction of combined devices, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of energy waste and the inability to recover the heat of industrial waste gas, so as to reduce the speed of ash accumulation, maintain smooth flow, and reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

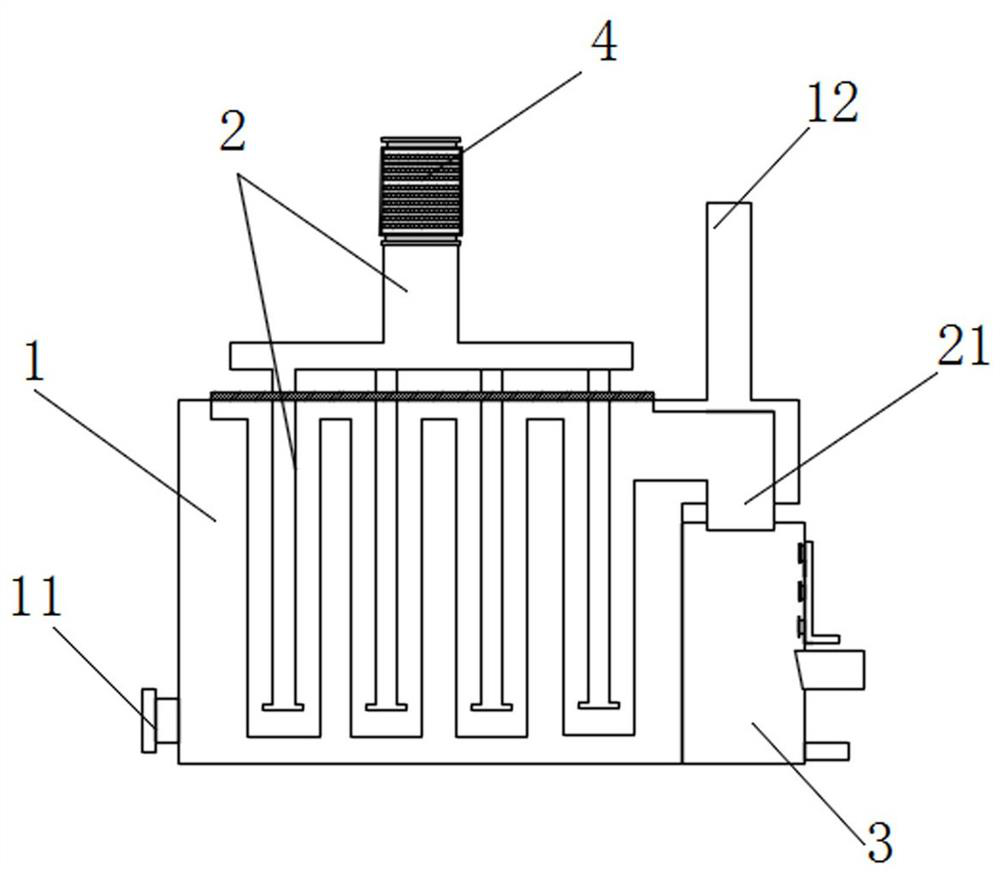

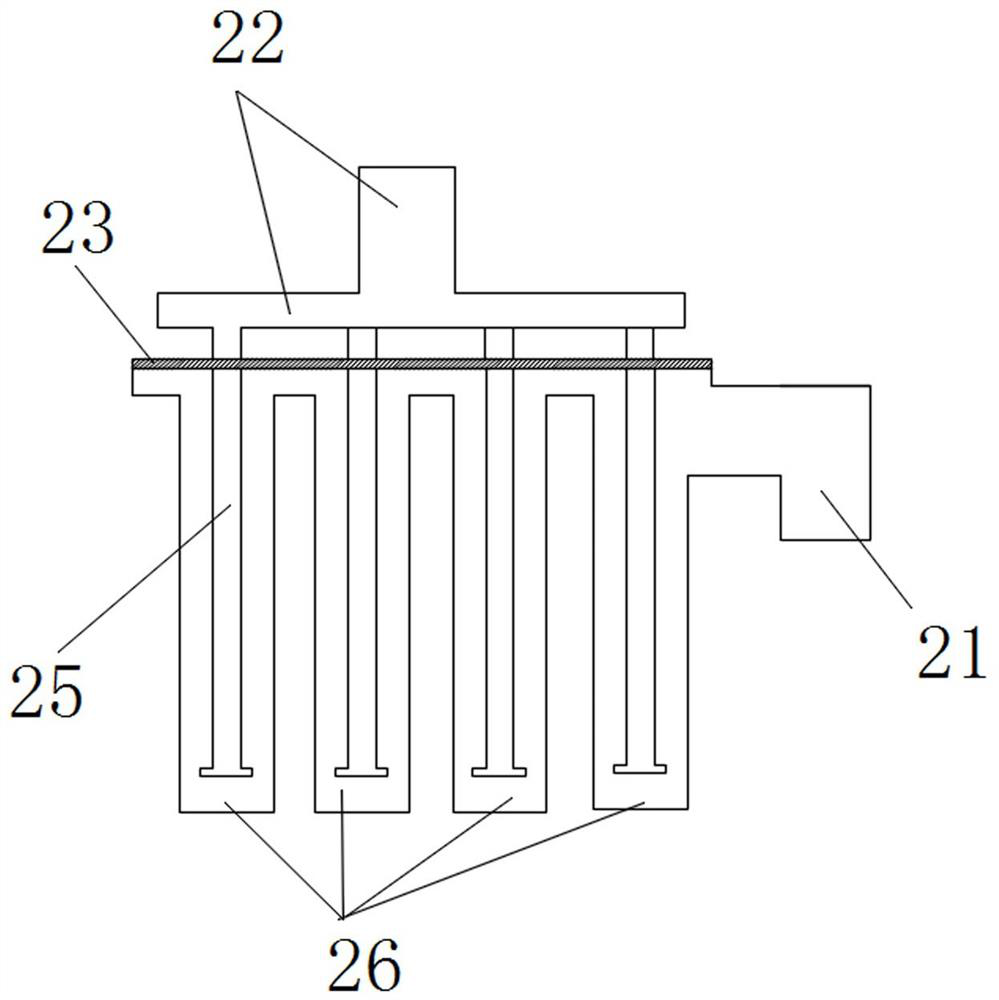

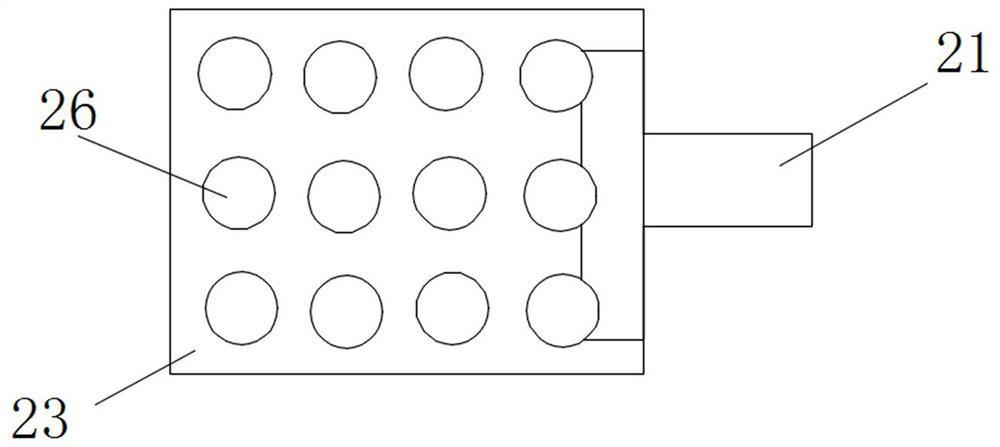

[0026] Such as Figure 1-5 As shown, an industrial waste gas heat recovery device of the present invention includes an evaporator 1 and a heat collection device 2 partially arranged in the cavity of the evaporator 1, and the heat collection device 2 includes a plurality of The heating tubes 26 distributed in a square matrix and the T-shaped smoke inlet 22 arranged above the evaporator 1, the plurality of heating tubes 26 are provided with a smoke branch pipe 25 in the inner cavity, and the plurality of smoke branch pipes 25 The smoke inlet ends are all welded on the horizontal section of the T-shaped smoke inlet 22, and a sealing plate 23 for preventing exhaust gas from overflowing is provided between the horizontal section of the T-shaped smoke inlet 22 and the upper ends of a plurality of heating pipes 26, and the said square One side of a plurality of heating pipes 26 distributed in a matrix is provided with a smoke outlet 21, and the end of the vertical section of the T-...

Embodiment 2

[0029] Based on Embodiment 1, the primary dust removal device 41 includes multiple layers of detachable filter screens 41 .

[0030] It is convenient to replace the filter screen regularly, so as to keep the primary dust removal device 4 unimpeded.

[0031] The spraying device 32 includes a plurality of spraying heads arranged on the side wall of the dust removal chamber 31 .

[0032] The exhaust gas outlet 33 is disposed on the lower side of the shower device 32 .

[0033] The present invention is an industrial waste gas heat recovery device. By arranging a plurality of heating pipes 36 distributed in a square matrix in the evaporator 1, the cold water entering from the water injection port 11 on the evaporator 1 can be more fully combined with the plurality of heating pipes. The contact greatly increases the energy absorption efficiency of cold water, and secondly, by setting on the T-shaped smoke inlet 22 and the secondary dust removal device 3, the dust accumulation speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com