Non-woven fabric and preparation method thereof

A technology of non-woven fabrics and fabrics, applied in non-woven fabrics, textiles and papermaking, and liquid repellent fibers, etc., can solve the problems of slow removal of moisture and moisture, hidden dangers of hygiene, and inability to meet the needs of dryness. , to achieve good water blocking function and prevent infiltration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

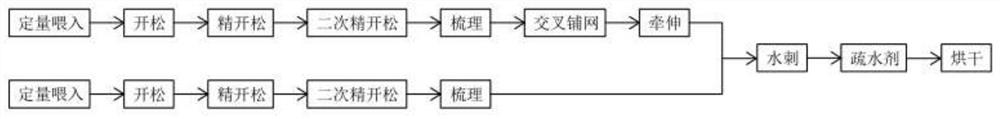

[0048] Secondly, the present invention also provides a kind of preparation method of described non-woven fabric, and it comprises the steps:

[0049] S1 prepares the first nonwoven fiber web:

[0050] The raw material of the first non-woven fiber web is subjected to quantitative feeding, opening, fine opening, secondary fine opening, carding, cross-lapping, and drafting processes to obtain the first non-woven fiber web;

[0051] S2 prepares polylactic acid fiber web:

[0052] Polylactic acid fiber webs are obtained after quantitative feeding, opening, fine opening, secondary fine opening, and carding of polylactic acid fiber raw materials;

[0053] S3 The first non-woven fiber web treated in step S1 and the polylactic acid fiber web treated in step S2 are superimposed into one through hydroentanglement, soaked in a hydrophobic agent, and dried to make a finished non-woven fabric.

Embodiment 1

[0056] The bamboo fiber material is subjected to quantitative feeding, opening, fine opening, secondary fine opening, carding, cross-lapping, and drafting processes to obtain the first non-woven fiber web;

[0057] S2 prepares polylactic acid fiber web:

[0058] Polylactic acid fiber webs are obtained after quantitative feeding, opening, fine opening, secondary fine opening, and carding of polylactic acid fiber raw materials;

[0059] S3 The first non-woven fabric fiber web treated in step S1 and the polylactic acid fiber web treated in step S2 are bonded together by spunlace, infiltrated with a hydrophobic agent, and dried to make a finished non-woven fabric.

[0060] The hydrophobic agent is infiltrated between the first non-woven fiber web and the polylactic acid fiber web.

[0061] The specific S3 steps are:

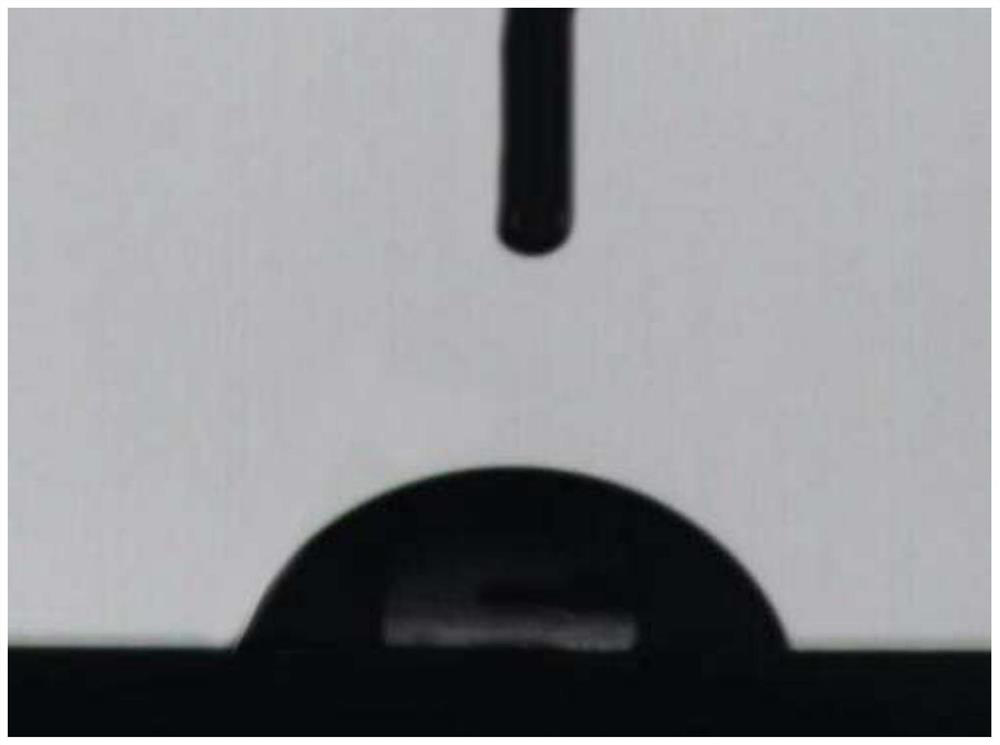

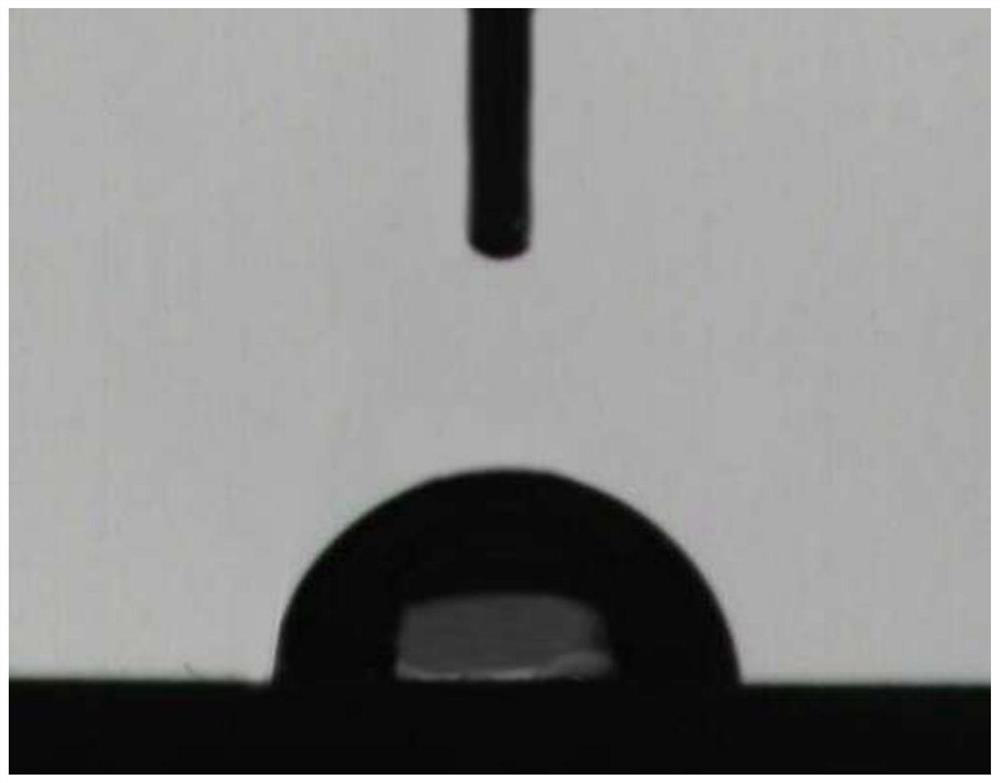

[0062] The first non-woven fiber web treated in step S1 and the polylactic acid fiber web treated in step S2 are hydroentangled. After mixing the hyperbranched po...

Embodiment 2

[0065] The bamboo fiber material is subjected to quantitative feeding, opening, fine opening, secondary fine opening, carding, cross-lapping, and drafting processes to obtain the first non-woven fiber web;

[0066] S2 prepares polylactic acid fiber web:

[0067] Polylactic acid fiber webs are obtained after quantitative feeding, opening, fine opening, secondary fine opening, and carding of polylactic acid fiber raw materials;

[0068] S3 The first non-woven fabric fiber web treated in step S1 and the polylactic acid fiber web treated in step S2 are bonded together by spunlace, infiltrated with a hydrophobic agent, and dried to make a finished non-woven fabric.

[0069] The specific S3 steps are:

[0070] The first non-woven fiber web treated in step S1 and the polylactic acid fiber web treated in step S2 are hydroentangled.

[0071] After mixing hyperbranched polyester and linear aliphatic acid evenly, add 0.3% catalyst p-toluenesulfonic acid of the total weight of raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com