Method and side blowing device for improving rh refining decarburization rate of ultra-low carbon steel

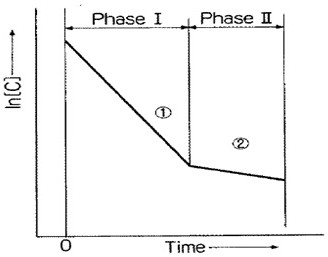

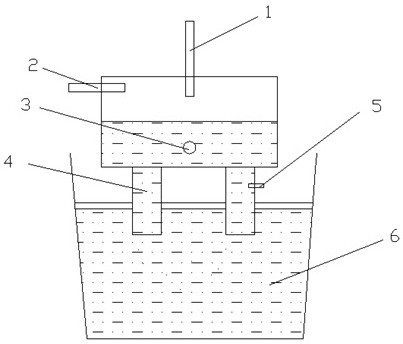

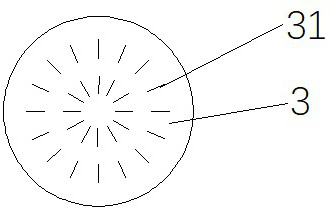

An ultra-low carbon steel and decarburization technology, applied in a method and a side blowing device to improve the RH refining and decarburization rate of ultra-low carbon steel, can solve the problem of not effectively improving the RH decarburization rate, limited decarburization rate improvement ability, The feasibility of the measures is not very high, so as to achieve the effect of good decarburization effect, good molten steel cleanliness, and strong promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

[0045] Embodiment 1-7: The method for increasing the decarburization rate of ultra-low carbon steel RH refining adopts the following specific processes.

[0046] (1) The process of this method is as follows: after the converter is tapped, LF treatment is performed after top slag treatment, and then RH refining is performed; the process steps of RH refining are as follows.

[0047] Step 1: The temperature of the RH molten steel entering the station is 1610°C-1630°C, the carbon content is 0.03wt%-0.05wt%, and the oxygen content is 0.025wt%-0.45wt%.

[0048] Step 2: After the ladle is refined by RH, raise the ladle for vacuuming operation. After the vacuum degree drops to 200mbar or below, carry out the oxygen blowing decarburization operation with the lowering top lance; the oxygen blowing flow rate is determined according to the oxygen content in the steel, and the oxygen blowing amount It is determined according to the steel tapping amount of the converter, the oxygen content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com