High-pressure natural gas dealkylation device

A technology for natural gas and hydrocarbon removal, which is applied in the direction of gas fuel, gas treatment, and dispersed particle filtration, etc. It can solve the problems of high overall operating cost, large floor area, and large system energy consumption, and achieves reduced floor space and reduced The effect of reducing production and operation costs and system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

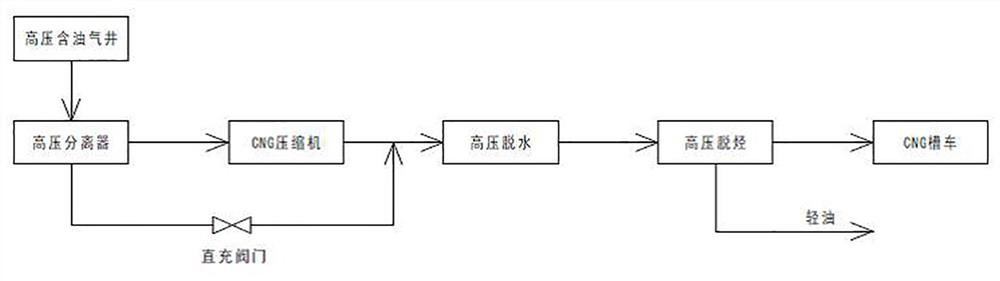

[0039] Such as Figure 4 As shown, a high-pressure natural gas dehydrogenation device includes a pre-separator 2 , a first adsorption tower 4 , a second adsorption tower 5 and a dust filter 12 .

[0040] A first pipeline A comprising two valves V is set, one end of the first pipeline A is connected to the front end of the first adsorption tower 4 , and the other end is connected to the front end of the second adsorption tower 5 .

[0041] The two valves V of the first pipeline A are connected to the pre-separator 2 through a pipeline, and the pre-separator 2 is connected to the air inlet 1 through a pipeline.

[0042] A second pipeline B comprising two valves V is provided, one end of the second pipeline B is connected to the rear end of the first adsorption tower 4 , and the other end is connected to the rear end of the second adsorption tower 5 .

[0043] The second pipeline B is connected to the dust filter 12 through a pipeline between the two valves V, and the dust filte...

Embodiment 2

[0045] In this embodiment, the similarity with Embodiment 1 will not be repeated here, the difference is:

[0046] Such as Figure 5 As shown, set a third pipeline C containing two valves V, the two ends of the third pipeline C are connected in parallel with the two ends of the first pipeline A, set a fourth pipeline D containing two valves V, the fourth The two ends of the pipeline D are connected in parallel with the two ends of the second pipeline B, and a fifth pipeline E including two valves V is provided, and the two ends of the fifth pipeline E are connected in parallel with the second pipeline B and the fourth pipeline D.

[0047] A sixth pipeline F is provided, one end of the sixth pipeline F is connected to the pipeline between the two valves V of the first pipeline A, and the other end is connected to the pipeline between the two valves V of the fourth pipeline D.

[0048] Set a seventh pipeline G, one end of the seventh pipeline G is connected to the pipeline betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com