Machining method of multi-featured thin-walled plate parts based on blank initial residual stress release

A residual stress and stress relief groove technology, applied in the field of machining, can solve problems such as deformation of parts, and achieve the effect of ensuring machining quality and inhibiting deformation of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

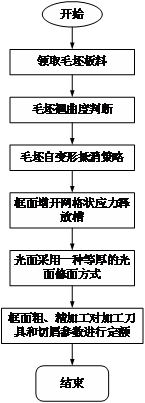

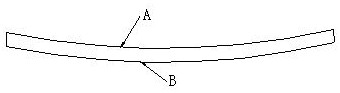

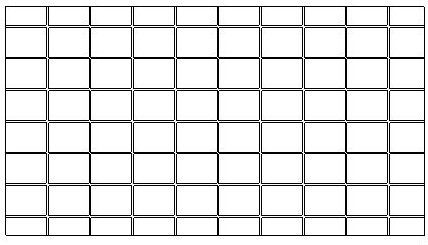

[0030] Refer to the attached figure 1 , this embodiment discloses a machining method for multi-featured thin-walled plate parts based on the release of the initial residual stress of the blank. First, due to the influence of the initial residual stress of the blank, the blank has a certain degree of warpage before processing. A blank self-deformation offset strategy is used to offset the deformation caused by the release of blank residual stress during part processing; then the processing tool and chip parameters during frame surface processing are rationed, and finally for frame surface processing, the traditional shaving step is canceled , use mesh cutting to add mesh stress relief slots, the specific operation is as follows:

[0031] S1. Receive the blank sheet, and then use the dial indicator to judge the warpage of the blank surface, and adopt a blank self-deformation offset strategy to offset the deformation caused by the release of the blank residual stress during the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com