Continuous production line for preparing export tea by using exogenous enzymes

An exogenous enzyme and production line technology, applied in the field of tea processing, can solve problems such as poor taste and unstable blending quality, and achieve the effects of improving cleaning and drinking safety, avoiding secondary processing pollution, and having a strong taste of glycol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

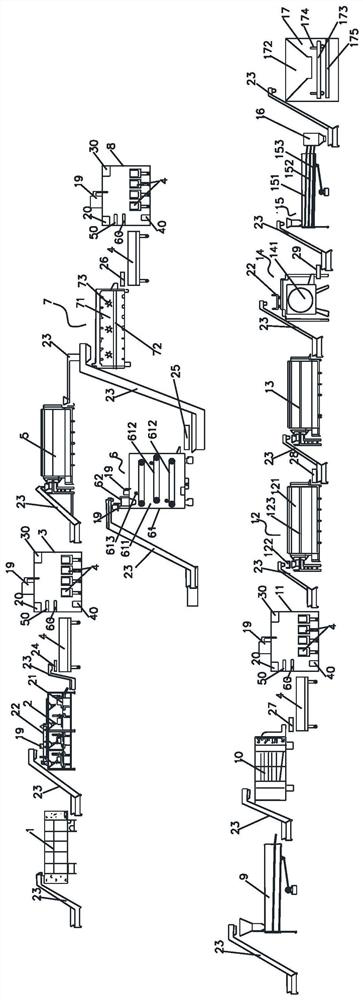

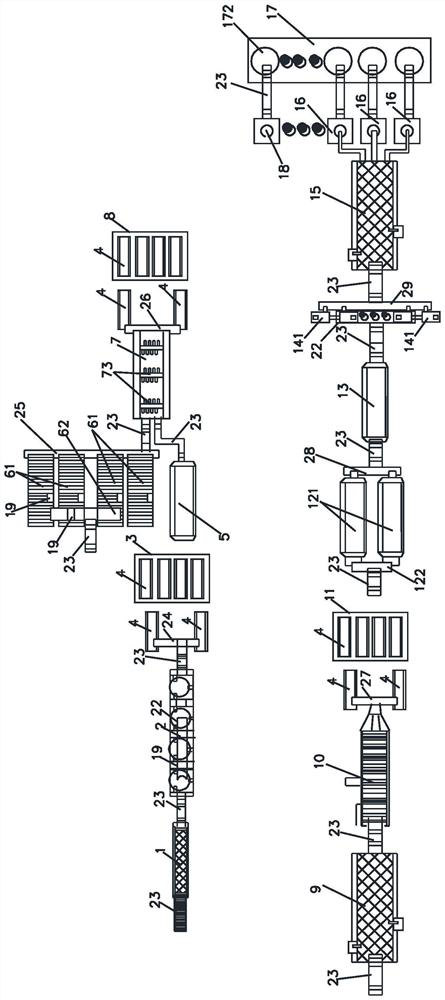

[0018] example, as figure 1 As shown, a continuous production line for preparing tea for export by using exogenous enzymes includes a withering machine 1, a rolling unit 2, a first fermentation stacking chamber 3, and a first fermentation stacking chamber connected together by a conveying device in sequence. The movable spreading platform 4 and the saccharification machine 5 in the room 3 also include a moisturizing and softening unit 6, and the outlet of the moisturizing and softening unit 6 and the saccharification machine 5 are connected to the mixer 7 through a conveying device. After the mixer 7, the second fermentation stacking chamber 8, the shaker 9, the dryer 10, the third fermentation stacking chamber 11, the shaping machine 12, the Titian sterilizer 13, The car color unit 14 , the shaking screen classifier 15 , the storage bin 16 arranged after the shaking screen classifier 15 , and the leveling machine 17 for the leveling of tea leaves.

[0019] Refer below figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com