Silicon-carbon composite material and its preparation method and lithium-ion battery

A technology of silicon-carbon composite materials and lithium-ion batteries, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem that it is difficult to realize the uniform distribution and effective contact of silicon and carbon, and limit the practical application of high-performance silicon-carbon composite materials. Effectively suppress problems such as the agglomeration of nano-silicon particles, and achieve the effects of alleviating the destructive effect of the internal stress of the electrode, high strength, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

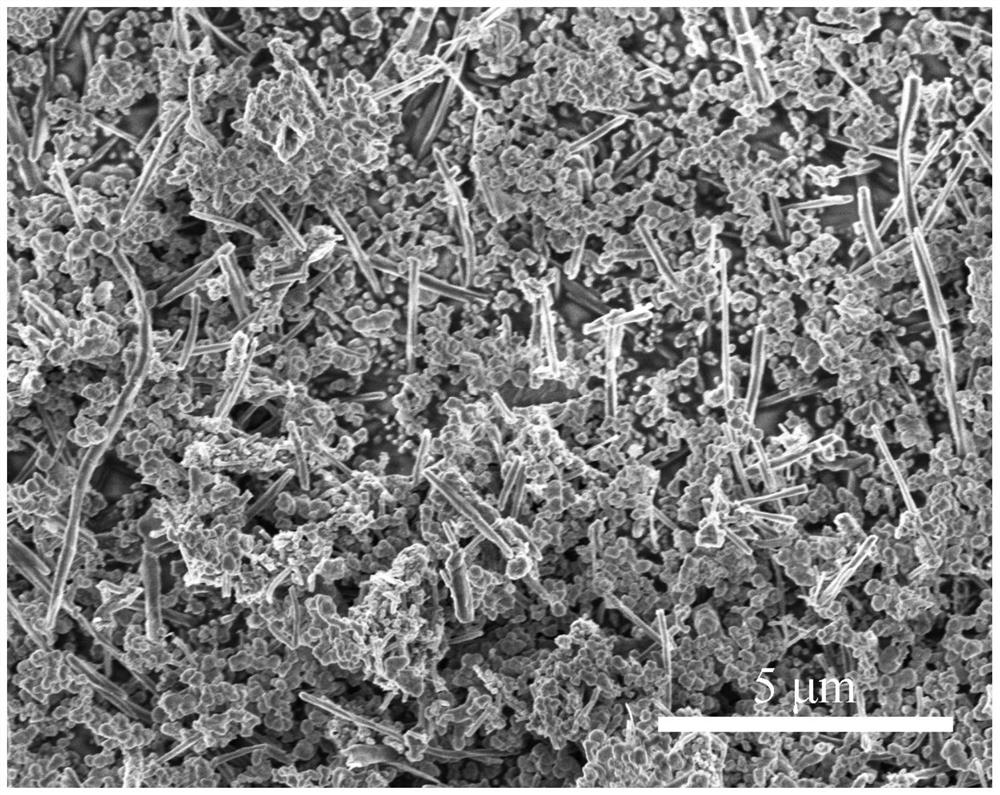

[0042] The preparation method of a silicon-carbon composite material provided by the present invention comprises: mixing a silicon material modified by ultraviolet-ozone or an oxidant with a carbon material modified by ultraviolet-ozone to obtain the silicon-carbon composite material. The functional groups with opposite electrical properties are uniformly introduced into the surface of carbon and / or silicon materials, and the electrostatic attraction between carbon and silicon surfaces solves the problem of uneven distribution and effective contact between the components of carbon and silicon materials, thereby improving the performance of silicon-carbon materials. Electrochemical cycling performance of composites.

[0043] In some preferred embodiments of the present invention, the mass ratio of the carbon material to the silicon material is 8-2:2-8 (such as 8:2, 7:3, 5:5, etc.), more preferably The ratio is 8~5:2~5.

[0044] In some preferred embodiments of the present inve...

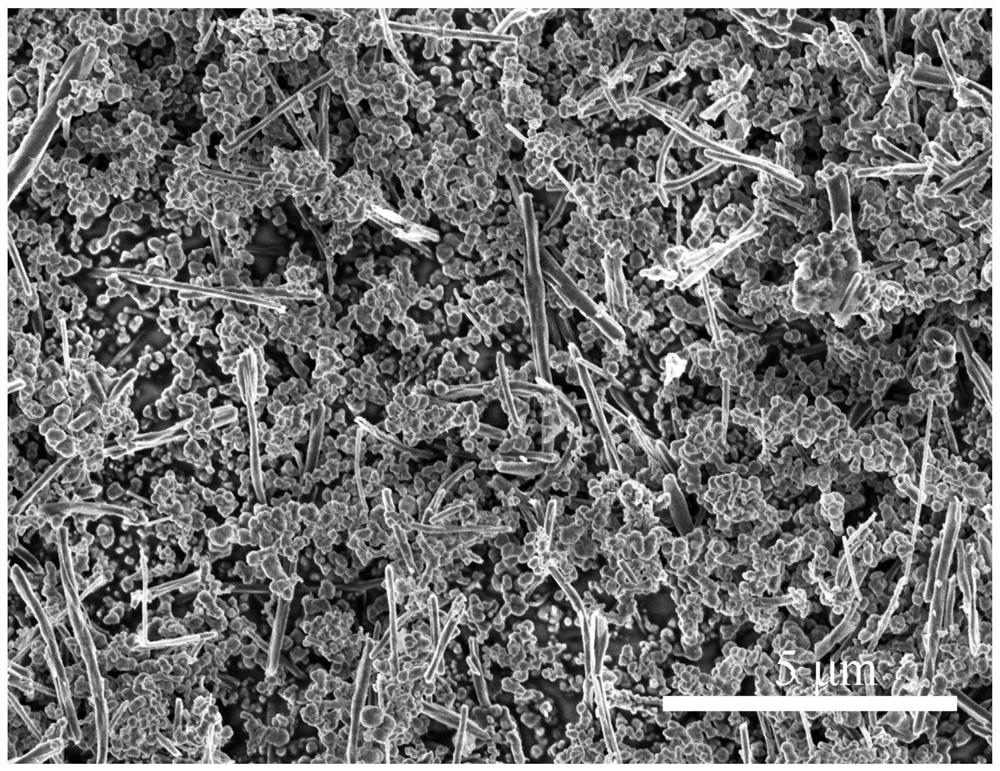

Embodiment 1

[0063] The materials used in this embodiment are:

[0064] Silicon material: nano-silicon (Si) particles, (average particle size 50nm);

[0065] Carbon material: choose carbon fiber (CNFs);

[0066] The mass ratio of nano silicon and carbon fiber is 70.05:29.95.

[0067] The synthetic method of described composite material specifically comprises the following steps:

[0068] (1) UV-ozone joint modified carbon material:

[0069] At a temperature of 150°C and a wavelength of 253.7nm, use a UVO-Cleaner (ultraviolet ozone cleaning machine) to carry out ultraviolet-ozone treatment. After irradiating 200mg of CNFs for 20 minutes, the surface of the CNFs has carboxyl functional groups, which are labeled as o-CNFs ;

[0070] (2) Surface chemically modified silicon material:

[0071] 500mg Si nanoparticles in piranha solution (3:1, V / V H 2 SO4:H 2 o 2 , the mass concentration of hydrogen peroxide is 75%), keep the solution at 80°C, stir for 1h, then use ultrapure water to filte...

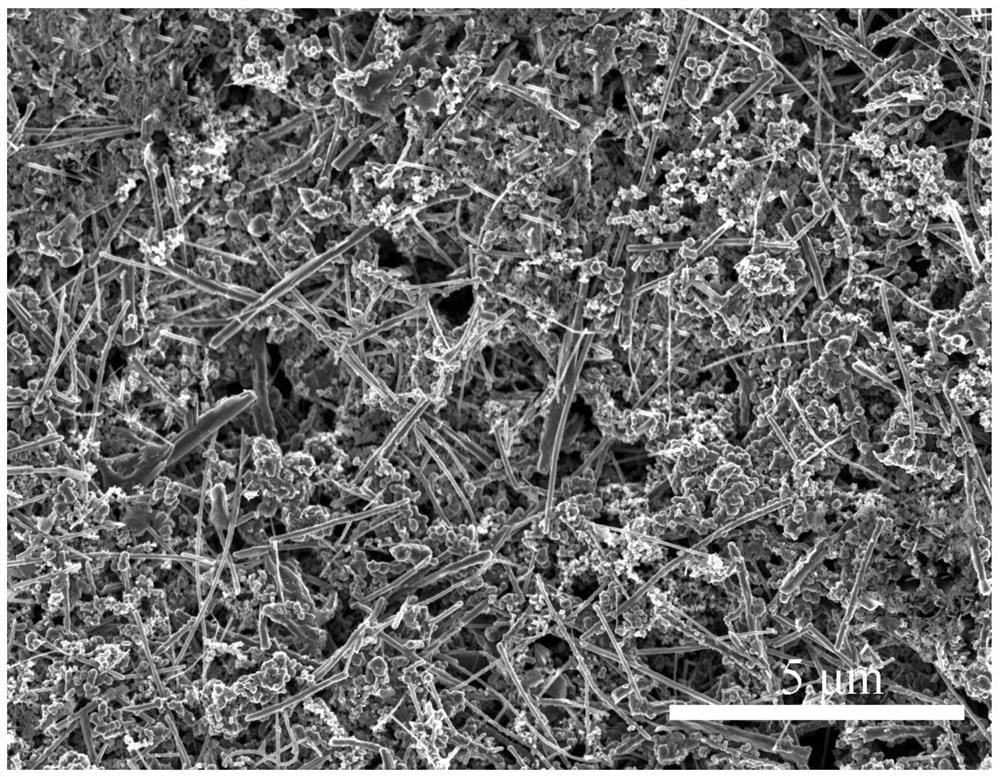

Embodiment 2

[0074] The materials used in this embodiment are:

[0075] Silicon material: nano-silicon (Si) particles (average particle size 50nm);

[0076] Carbon material: choose carbon fiber (CNFs);

[0077] The mass ratio of nano silicon and carbon fiber is 1:1.

[0078] For the modification of carbon material, step (1) is identical with embodiment 1;

[0079] (2) UV-ozone joint modified silicon material:

[0080] Use UVO-Cleaner for UV-ozone treatment at a temperature of 150°C and a wavelength of 253.7nm. After irradiating 300mg of Si nanoparticles for 20 minutes, the silicon surface has hydroxyl functional groups, which are marked as SiO x ;

[0081] (3) Ball milling and mixing to make silicon-carbon composite powder:

[0082] Mix 130mg o-CNFs with 130mg SiO x Mix 1.5mL in absolute ethanol, wet mill at a ball milling speed of 500rpm for 1h, and vacuum dry at 50°C for 12h to obtain a silicon-carbon composite powder with a uniform interwoven structure, labeled as Si-o-o-CNFs, It...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com