An automatic control system and control method for an ammonia on-line analyzer

A technology of automatic control system and control method, which is applied in the general control system, control/regulation system, program control in sequence/logic controller, etc., can solve the problems of manual measurement, inaccurate measurement, poor timeliness of measurement, etc., to achieve Ensure the environment and human health, reduce human control, sampling and analysis accuracy and high timeliness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

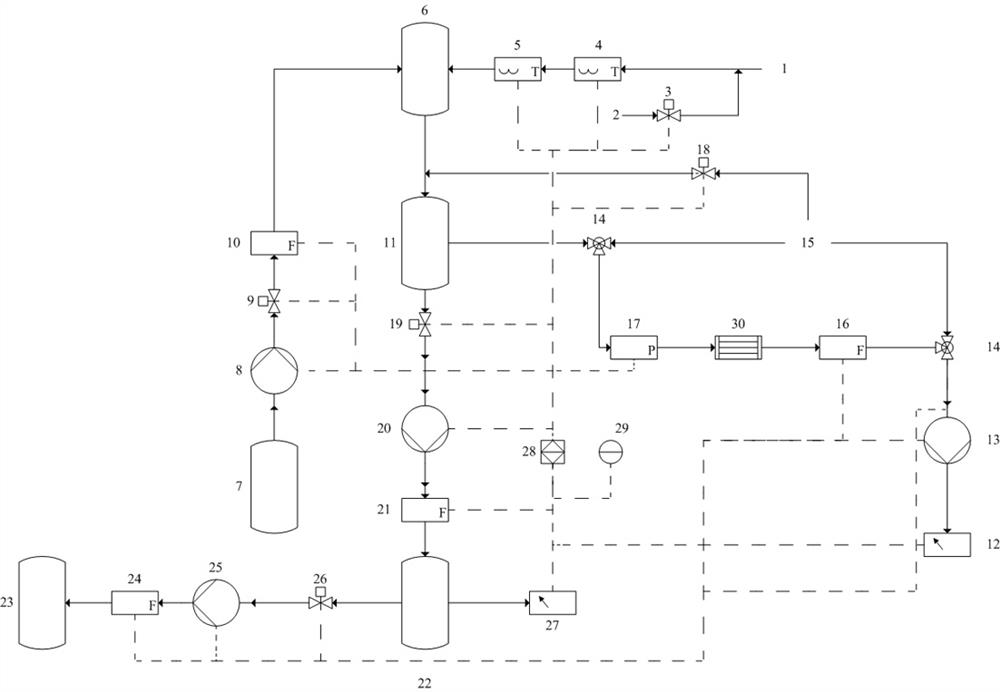

[0038] figure 1 It shows an automatic control system for an online ammonia analyzer of an embodiment of the present invention, which includes a human-computer interaction unit, a data acquisition and automatic control unit, a sampling unit, a flue gas flow control unit, an absorption constant volume unit and a continuous flow analysis unit; The sampling unit includes a sampling gun 1; the absorption constant volume unit includes a new liquid bottle 7, a new liquid replenishment pump 8, a new liquid replenishment pump outlet solenoid valve 9, a new liquid flow meter 10, a mixing bottle 6, and an absorption bottle 11 connected sequentially by pipelines , sample delivery pump inlet solenoid valve 19, sample delivery pump 20, sample delivery flow meter 21, buffer bottle 22, waste liquid discharge pump inlet solenoid valve 26, waste liquid discharge pump 25, waste liquid flow meter 24 and waste liquid bottle 23, The sampling gun 1 is connected with the mixing bottle 6; the flue gas...

Embodiment 2

[0040] The automatic control system of the ammonia on-line analyzer in the above embodiment of the present invention can also be improved as follows, the sampling unit also includes a probe temperature control device 4, an instrument box temperature control device 5, a probe purge pneumatic valve 3, and a compressed air pipeline 2 for sampling The gun 1 is connected to the probe temperature control device 4 and the instrument box temperature control device 5 in turn, and is connected to the mixing bottle 6. The compressed air pipeline 2 is connected to the probe purge pneumatic valve 3, and the probe purge pneumatic valve 3 is connected to the probe temperature control through the sampling gun 1. Device 4 is connected;

[0041] Among them, the start of the system depends on: 1. Press the system start button; open the vacuum breaker valve 18, delay 5 seconds; 2, open the outlet valve 9 of the new liquid replenishment pump, start the new liquid replenishment pump 8, delay 30 seco...

Embodiment 3

[0069] A control method for an automatic control system of an ammonia on-line analyzer, comprising the following steps,

[0070]S1: Constant volume of the absorption liquid, according to the signals of the new liquid flow meter 10 and the waste liquid flow meter 24, select a flow rate between 10 and 15 minutes, record the volume V1 of the absorption liquid, and the recording unit is milliliters, including the new liquid flow meter 10 sends flow feedback to PLC28, waste liquid flow meter 24 sends flow feedback to PLC28, PLC28 calculates the volume V1 of the absorption liquid, wherein, the process of absorbing constant volume is controlled by the automatic control module in the data acquisition and automatic control unit, and the peristaltic pump receives automatic control The start-stop signal sent by the module; the automatic process includes the initial startup of dosing, dosing during normal operation, the stop of the dosing equipment in a fault state, running the new liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com