Preparation and application of a znsn electrode for electrochemical reduction of carbon dioxide

A carbon dioxide and electrochemical technology, applied in the direction of electrodes, electrolytic components, electrolytic process, etc., can solve the problems of lower catalyst utilization rate and small specific surface area of Zn nanoparticles, so as to reduce the mass transfer polarization resistance and increase the reactive area , the effect of simple deposition method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

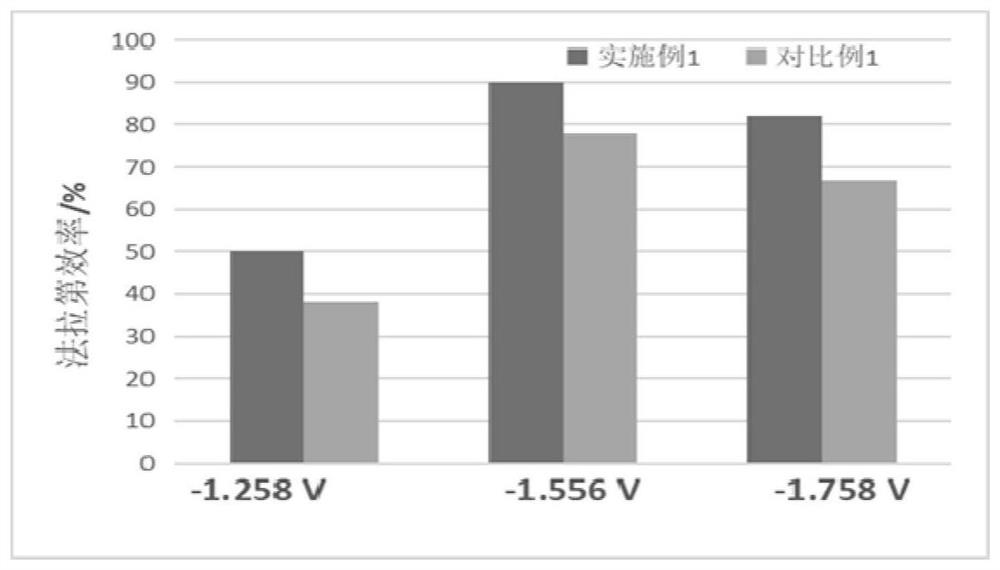

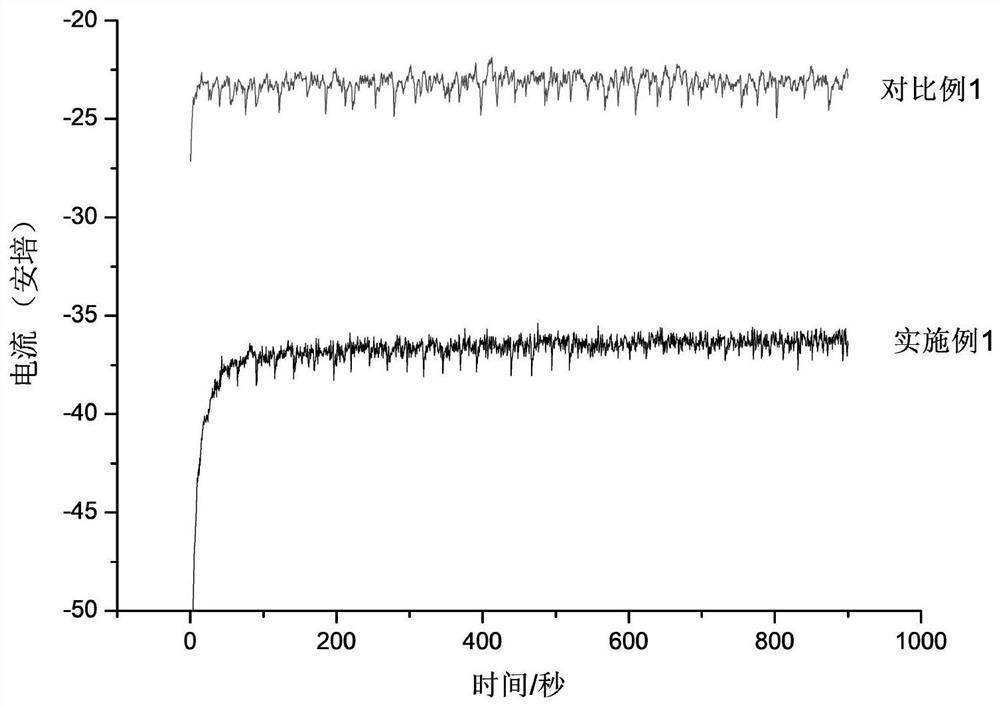

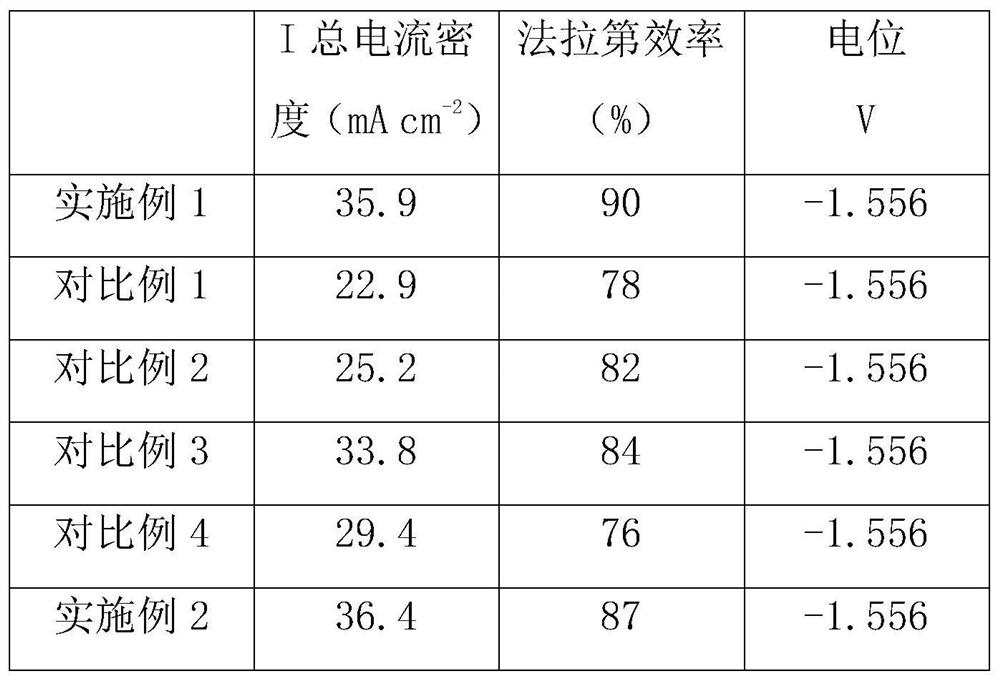

[0040] Treat carbon felt and carbon paper in the air at 500°C, then degrease and clean them in ethanol and acetone as the base layer; ZnCl with a concentration of 0.05mol / L 2 Aqueous solution and SnCl with a concentration of 0.2mol / L 2 Aqueous solution and HCl with a concentration of 0.05mol / L are mixed; the molar ratio of Zn to Sn is 5:12; and 0.05mol / L polyvinylpyrrolidone with a molar ratio of Zn to polyvinylpyrrolidone of 1:2 is added to the above mixture , using a current density of -60mA / cm 2 The constant current is deposited for 2000s, and the ZnSn catalyst is deposited on the surface of the base layer; the electrode with the ZnSn electrodeposited layer is placed in a reactor with a polytetrafluoroethylene sleeve, and 300ppm of ascorbic acid aqueous solution is added. 20% to 60% of the volume of the reaction solution, react at 180 ° C for 12 hours and then cool down to room temperature naturally; after washing and drying, place the heat-treated electrode in CO 2 0.5mo...

Embodiment 2

[0050] Treat carbon felt and carbon paper in the air at 500°C, then degrease and clean them in ethanol and acetone as the substrate; ZnCl with a concentration of 0.08mol / L 2 Aqueous solution and SnCl with a concentration of 0.2mol / L 2 Aqueous solution and HCl with a concentration of 0.08mol / L are mixed; the molar ratio of Zn and Sn is 1:3; Trimethyl ammonium chloride was added to the above mixed solution, and the constant current density was -40mA / cm2, deposited for 2400s, and the ZnSn catalyst was deposited on the surface of the base layer, and the electrode with the ZnSn electrodeposited layer was placed in a polyfour Add 500ppm of ascorbic acid aqueous solution to the reaction kettle with vinyl fluoride cover, the reaction solution volume accounts for 50% of the reaction kettle volume, react at 180°C for 12 hours and then cool down to room temperature naturally; after washing and drying, place the heat-treated electrode in in CO 2 The electrode was prepared by performing ...

Embodiment 3

[0052] Treat carbon felt and carbon paper in the air at 500°C, then degrease and clean them in ethanol and acetone as the substrate; ZnCl with a concentration of 0.05mol / L 2 Aqueous solution and SnCl with a concentration of 0.2mol / L 2 Aqueous solution and HCl with a concentration of 0.05mol / L are mixed; the molar ratio of Zn to Sn is 4:7; Alkyltrimethylammonium bromide is added to the above mixed solution, and a constant current density of -100mA / cm2 is used to deposit for 2000s to deposit a ZnSn catalyst on the surface of the base layer. Place the electrode with the ZnSn electrodeposited layer in a reaction kettle with a polytetrafluoroethylene sleeve, add 200ppm of amino acid aqueous solution, the volume of the reaction solution accounts for 50% of the reaction kettle volume, react at 180 ° C for 12 hours and then naturally Cool down to room temperature; after washing and drying, place the heat-treated electrode in CO 2 Saturated 0.5mol / L KHCO 3 The reduction was performe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com