500MPa-class weather-resistant bridge steel with impact power being not lower than 54J in welded heat-affected zone at minus 40 DEG C

A welding heat-affected zone and impact energy technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problem of insufficient low-temperature toughness, high strength, lack of comprehensive performance control of weldability, weather resistance, and multiple alloying components Insufficient research on design and regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

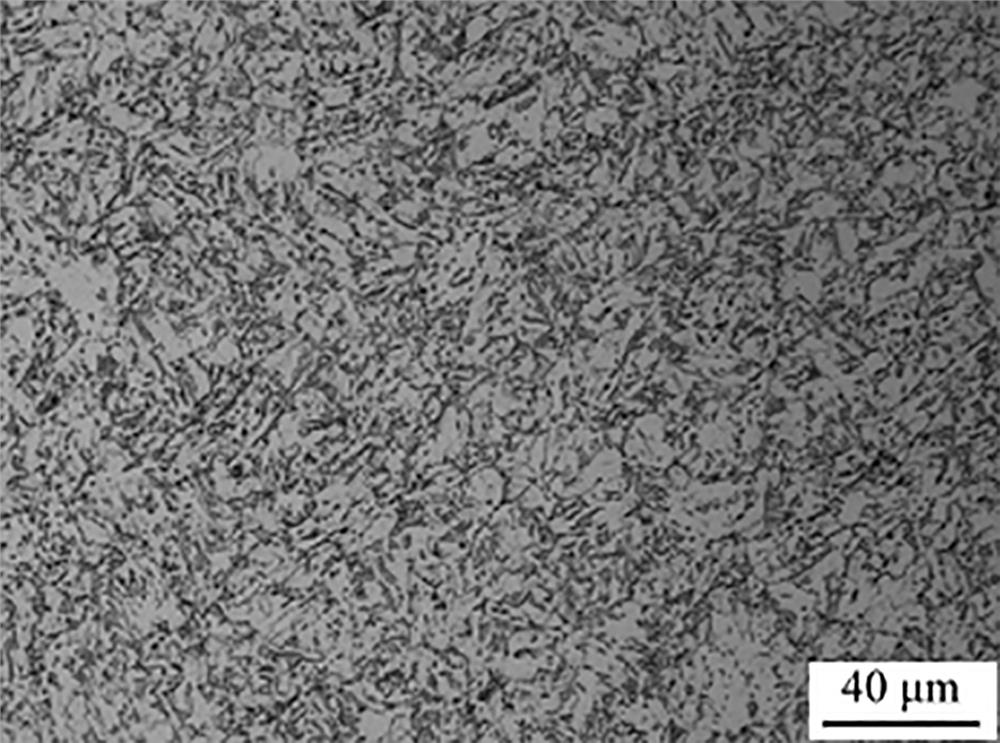

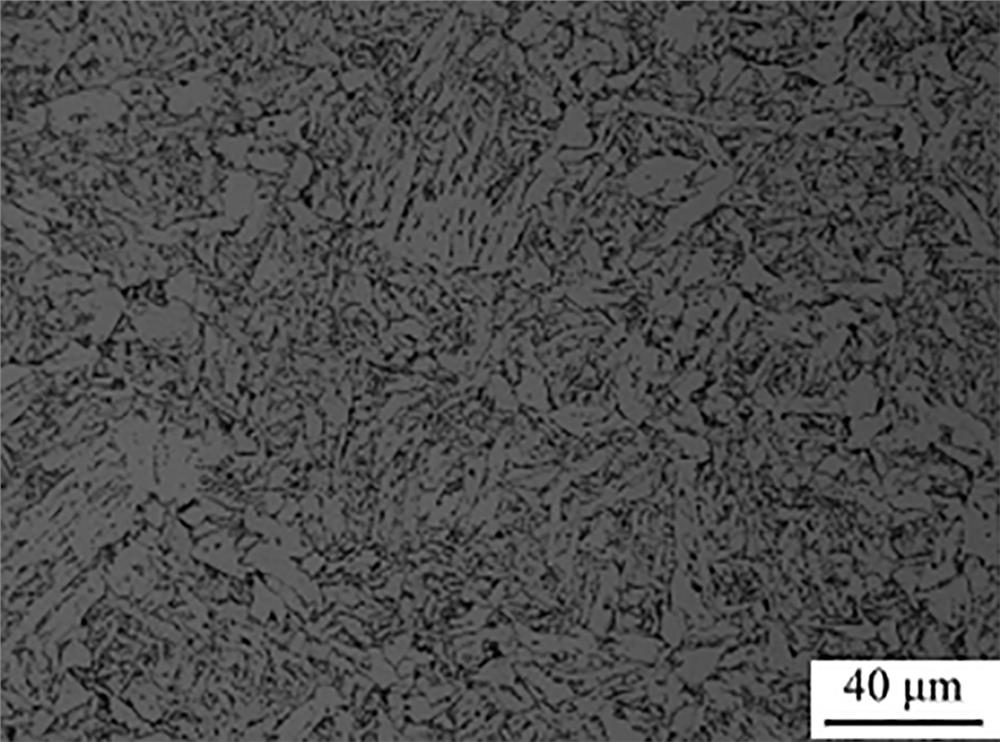

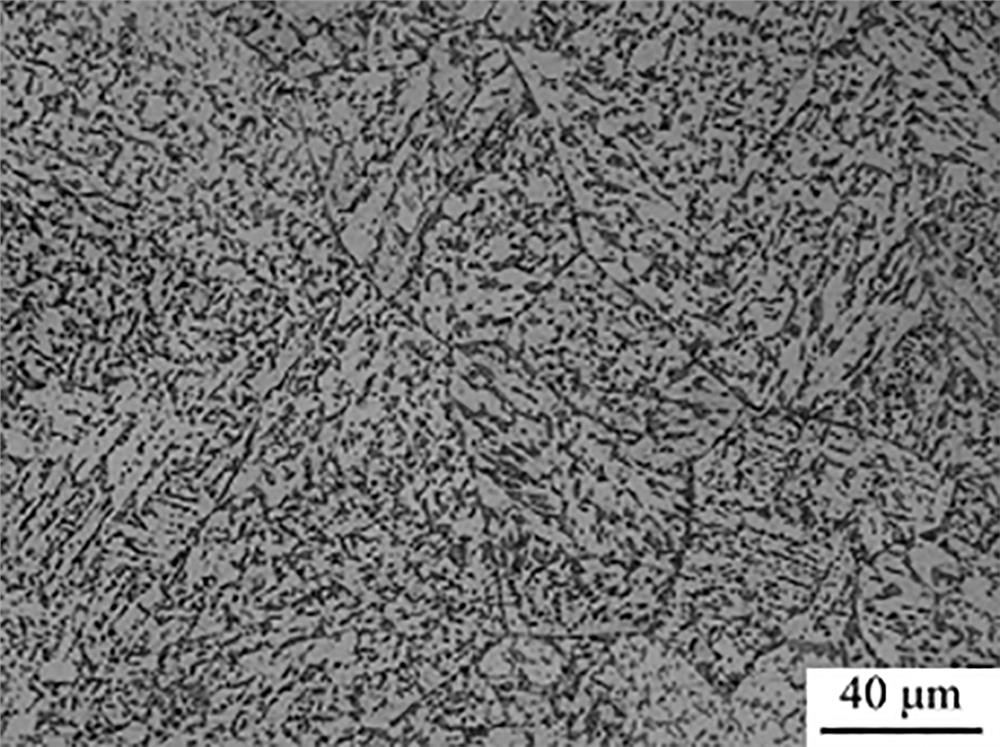

Image

Examples

preparation example Construction

[0063] Based on the above-mentioned weather-resistant bridge steel, the present invention also provides a method for preparing a 500MPa-level weather-resistant bridge steel plate with an impact energy of not less than 54J at -40°C in the welding heat-affected zone, which includes the preparation of steel billets, thermomechanical rolling and recycling Fire treatment in three steps.

[0064] (1) Steel billet preparation. Prepare raw materials according to the design requirements of weather-resistant bridge steel, put pure iron into the vacuum furnace, evacuate to 1 Pascal, heat the molten steel until it melts, refine the molten steel at high temperature and high vacuum for 15 minutes, fill the protective gas with argon, add alloy, adjust temperature, poured into steel ingots.

[0065] Among them, the chemical composition of the steel billet is controlled according to the following requirements in terms of weight percentage: C: 0.04-0.08, Si: 0.20-0.40, Mn: 1.35-1.70, Cr: 0.40-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com