Preparation method of alicyclic binary secondary amine

A technology of alicyclic diamine and cyclohexanediamine, which is applied in the fields of special chemicals and fine chemicals, can solve the problem of high reaction temperature, and achieve the effect of prolonging the operation time and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: A kind of preparation method of alicyclic divalent secondary amine

[0025] The invention discloses a method for preparing an alicyclic secondary secondary amine with high product yield, high purity, convenient operation, environmental friendliness, non-toxicity and pollution, and low reactivity.

[0026] This secondary amino group has a substituted alkyl group on the α-position carbon of the amino group, that is, the substituent on the N atom belongs to a secondary carbon-substituted alkyl group, and the steric hindrance effect is enhanced, effectively reducing the reactivity of the secondary amino group.

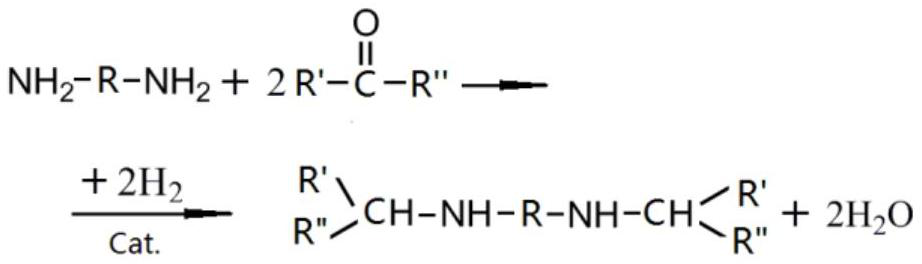

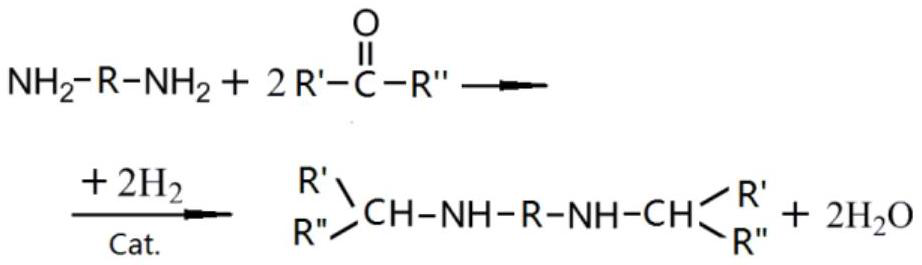

[0027] The reaction formula is as follows:

[0028]

[0029] The present invention adopts the ketone compound with the total carbon number above 4 as the raw material instead of the aldehyde compound, and its advantage is that the substituted alkyl group connected to the secondary amino group in the hydrogenation target product has a greater steric ...

Embodiment 2

[0044] Embodiment 2: A kind of preparation method of alicyclic divalent secondary amine

[0045] Put 147.5g (0.7mol) of 4,4'-diaminodicyclohexylmethane, 161.5g of methyl ethyl ketone (2.24mol) and 4.5g of palladium carbon catalyst into a stainless steel high-pressure reaction vessel, close the feeding port, and replace the reaction vessel with nitrogen The air in the medium is 3 times and the nitrogen is replaced with hydrogen for 3 times. The temperature is raised to control the temperature at 60°C, and the hydrogen is continuously introduced to control the hydrogen pressure at 4.0-4.5MPa. As the reaction progresses, the temperature can be increased appropriately, and the maximum reaction temperature is controlled at 95°C. Within the range, the hydrogen pressure is not greater than 6MPa. After 25 hours of reaction, cool down to room temperature and replace the residual hydrogen with nitrogen, release the pressure and return to normal pressure, and the reaction is over. The re...

Embodiment 3

[0046] Embodiment 3: A kind of preparation method of alicyclic divalent secondary amine

[0047] Put 147.5g (0.7mol) of 4,4'-diaminodicyclohexylmethane, 260.5g of methyl isobutyl ketone (2.6mol) and 4.5g of palladium carbon catalyst into a stainless steel high-pressure reaction vessel, close the feeding port, Replace the air in the reaction vessel with nitrogen for 3 times and replace the nitrogen with hydrogen for 3 times. Increase the temperature and control the temperature to 60°C. Continue to feed hydrogen and control the pressure of hydrogen to 4.0-4.3 MPa. As the reaction progresses, the temperature can be increased appropriately. The highest reaction The temperature is controlled within 95°C, and the hydrogen pressure is not greater than 6MPa. After 25 hours of reaction, cool down to room temperature and replace the residual hydrogen with nitrogen, release the pressure and return to normal pressure, and the reaction ends. The reaction product is filtered, and the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com