A kind of preparation method of hydrophobic and antibacterial decorative veneer

A thin wood and water-repellent technology, which is applied in the jointing of wooden veneers, wood heating, and manufacturing tools, etc., can solve the problems of poor hydrophobic and antibacterial properties, and achieve the effects of enhancing flexibility, not being easily damaged and deformed, and protecting human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

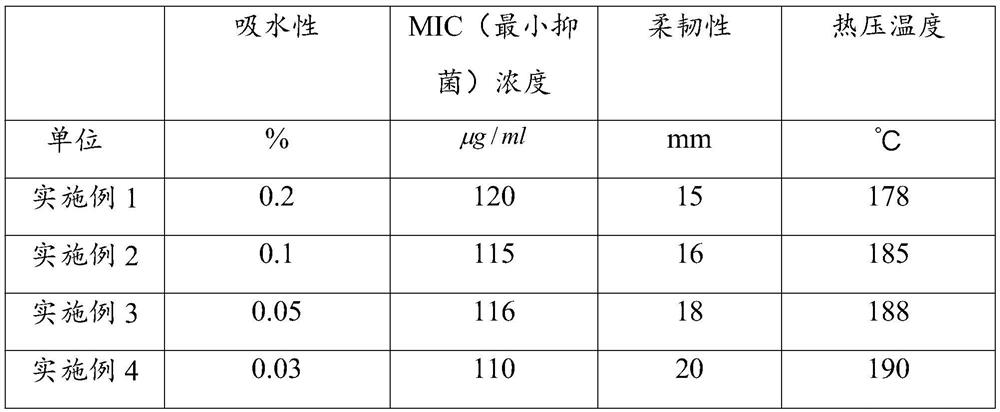

Examples

Embodiment 1

[0023] The invention provides a method for preparing a hydrophobic and antibacterial decorative veneer, which specifically comprises the following steps:

[0024] Step 1: First, select 1 piece of particleboard with a thickness of 0.8mm, 1 piece of MDF with a thickness of 0.8mm, and 1 piece of plywood with a thickness of 0.8mm, and put them all into the dryer , dried at 60°C for 10 minutes, dried to a moisture content of 8%, then completely removed from the dryer, and set aside for later use when cooled to 35°C;

[0025] Step 2: Add 40 parts of cotton fiber, 10 parts of hemicellulose, 20 parts of lignin, and 10 parts of polyester resin into the heating and stirring device at a heating temperature of 300°C and stir for 5 minutes at a speed of 100 rpm , after it is stirred evenly, add 3 parts of oxalic acid, 2 parts of silane coupling agent, and 2 parts of polyoxyethylene, then raise the internal temperature of the heating and stirring device to 400 ° C, and stir at a speed of 50...

Embodiment 2

[0032] The invention provides a method for preparing a hydrophobic and antibacterial decorative veneer, which specifically comprises the following steps:

[0033]Step 1: First, select 1 piece of particleboard with a thickness of 0.8mm, 1 piece of MDF with a thickness of 0.8mm, and 1 piece of plywood with a thickness of 0.8mm, and put them all into the dryer , dried at 60°C for 10 minutes, dried to a moisture content of 8%, then completely removed from the dryer, and set aside for later use when cooled to 35°C;

[0034] Step 2: Add 45 parts of cotton fiber, 15 parts of hemicellulose, 25 parts of lignin, and 15 parts of polyester resin into the heating and stirring device at a heating temperature of 300°C and stir for 5 minutes at a speed of 100 rpm , after it is stirred evenly, add 4 parts of oxalic acid, 2 parts of silane coupling agent, and 2 parts of polyoxyethylene, then raise the internal temperature of the heating and stirring device to 400 ° C, and stir at a speed of 50 ...

Embodiment 3

[0041] The invention provides a method for preparing a hydrophobic and antibacterial decorative veneer, which specifically comprises the following steps:

[0042] Step 1: First, select 1 piece of particleboard with a thickness of 0.8mm, 1 piece of MDF with a thickness of 0.8mm, and 1 piece of plywood with a thickness of 0.8mm, and put them all into the dryer , dried at 60°C for 10 minutes, dried to a moisture content of 8%, then completely removed from the dryer, and set aside for later use when cooled to 35°C;

[0043] Step 2: Add 50 parts of cotton fiber, 15 parts of hemicellulose, 30 parts of lignin, and 20 parts of polyester resin into the heating and stirring device at a heating temperature of 300°C and stir for 5 minutes at a speed of 100 rpm , after it is stirred evenly, add 4 parts of oxalic acid, 2 parts of silane coupling agent, and 2 parts of polyoxyethylene, then raise the internal temperature of the heating and stirring device to 400 ° C, and stir at a speed of 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com