Casting method for vermicular graphite cast iron cylinder cover of diesel engine and cold iron core support for casting

A diesel engine and vermicular graphite cast iron technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problems of high scrap rate and achieve the effects of eliminating shrinkage porosity, shrinkage porosity defects, and oxidation slag defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] as above and figure 1 As shown in , the fuel injector hole of the vermicular graphite cast iron cylinder head of a diesel engine has a large thermal joint. When the molten iron solidifies, the volume shrinks when the molten iron transforms from liquid phase to solid phase. Porosity defects, and shrinkage mostly occurs in the core. Based on this, the casting method of the diesel engine vermicular graphite cast iron cylinder head and the cold iron support for casting of the present invention can effectively eliminate the fuel injection of the diesel engine vermicular graphite cast iron cylinder head by improving the casting structure and method at the hot joint. Shrinkage at the hole, improve the pass rate.

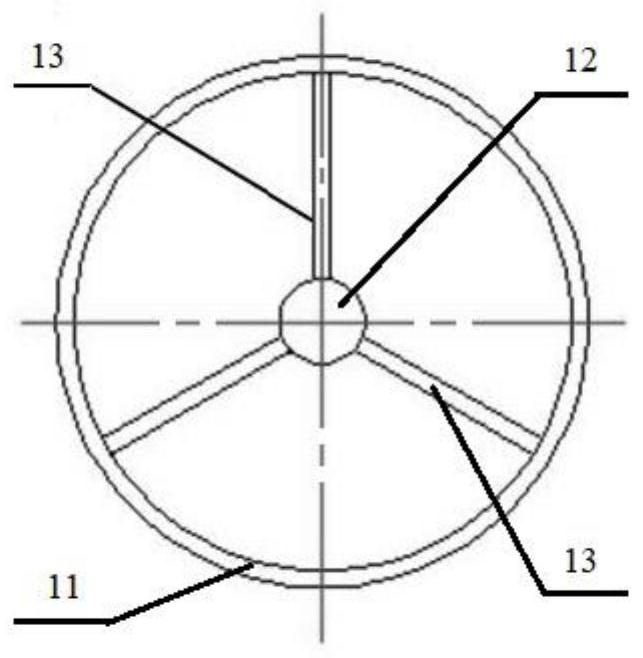

[0033] see figure 2 , image 3 and Figure 4 , the diesel engine vermicular graphite cast iron cylinder head casting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com