Method for casting vermicular graphite cast iron cylinder cover of diesel engine

A technology of vermicular graphite cast iron and cylinder head, which is applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of easy formation of shrinkage porosity or shrinkage cavity, pressure leakage of guide rod holes, and low pass rate, etc., to achieve Reduce the scrap rate, reduce the economic loss of the enterprise, and have strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] 18 mm diameter cylinder head guide rod holes in the cylinder head of the cast four-cylinder:

[0035] Order density greater than 1.7g / cm 3 A graphite rod with a length of 140mm and a diameter of 18mm.

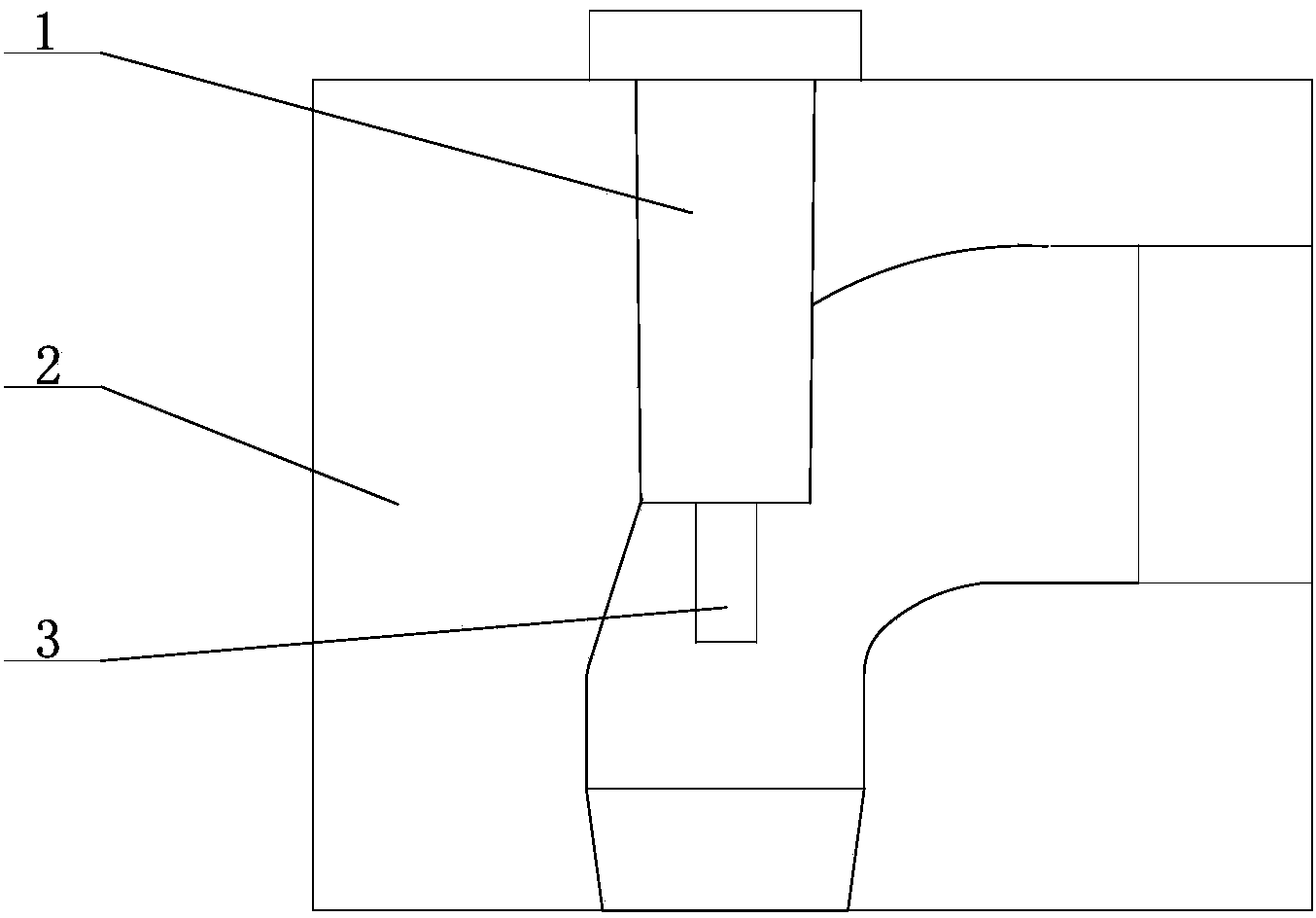

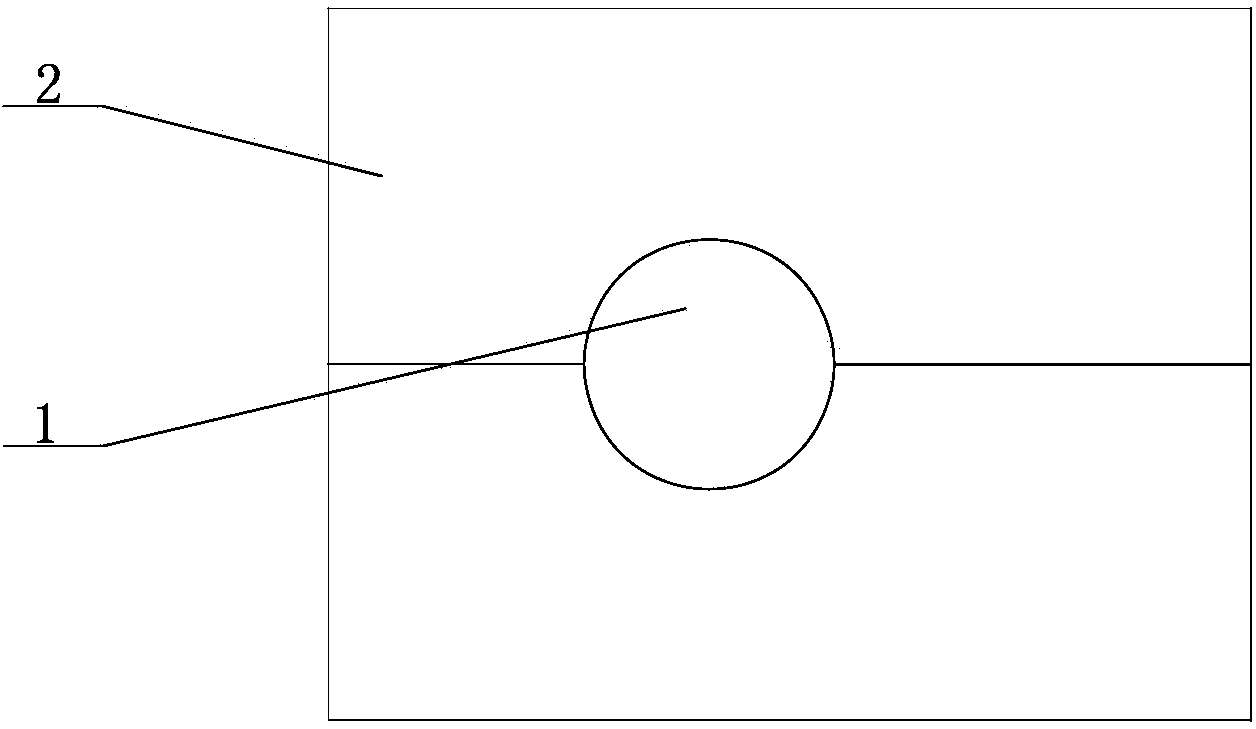

[0036] Drill a hole with a diameter of 18 mm in the center of the guide rod hole of the airway core box (to ensure accuracy and verticality), and use it to fix the positioning section 3 of the graphite rod with a diameter of 18 mm and a length of 40 mm.

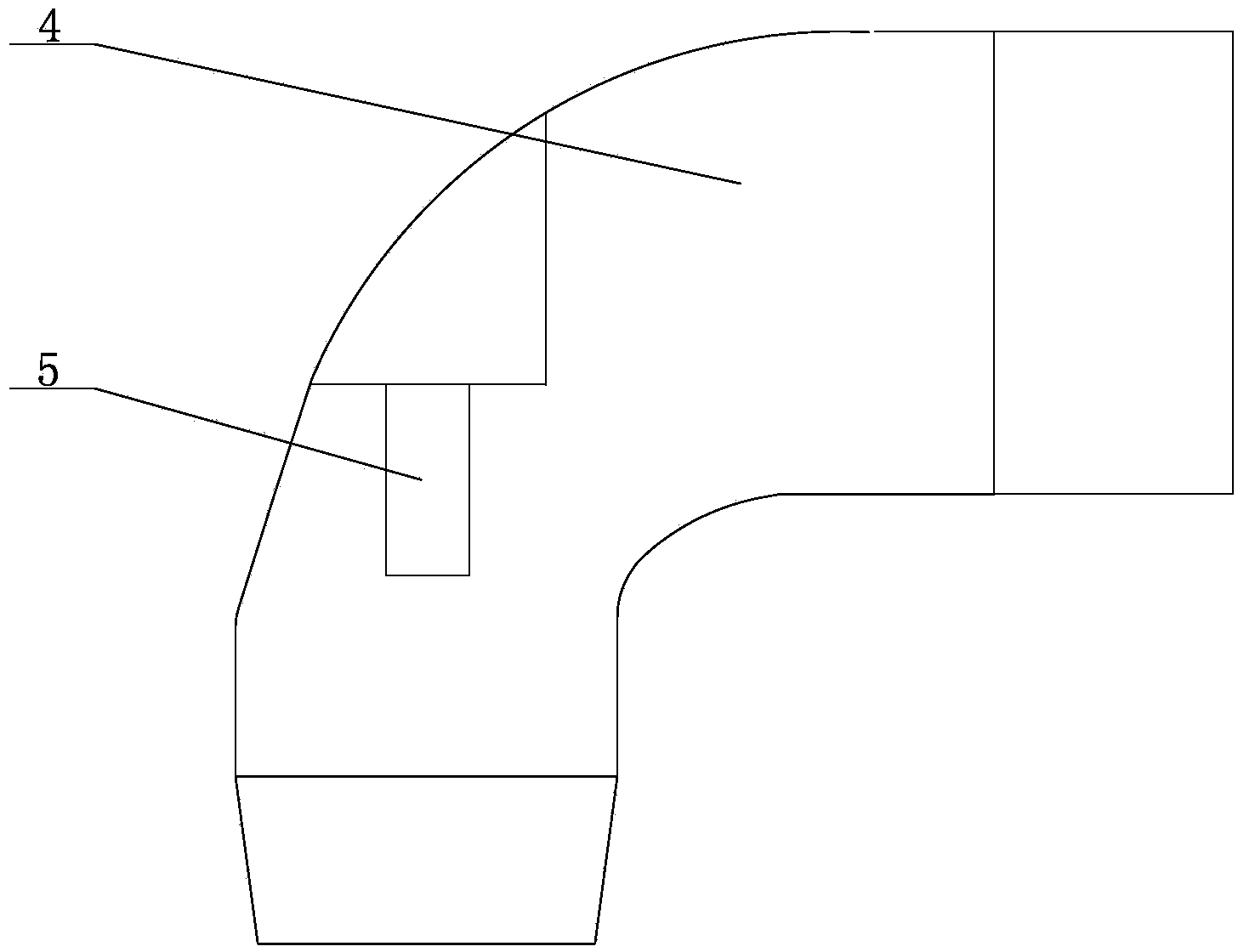

[0037] After the graphite cold iron and the airway core box are manufactured, a total of 4 airway sand cores are made, the positioning hole 5 of the graphite rod is sealed with newspaper, the paint is soaked twice, and dried to make the remaining sand cores and the upper and lower shapes of the cylinder head. Insert the graphite rod into the 4 graphite rod positioning holes 5 before the core is lowered. This method of placing the graphite inner cooling iron can prevent the graphite rod from breaking, difficult to clea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com