A kind of fluorine-free superhydrophobic surface and preparation method thereof

A super-hydrophobic surface and substrate surface technology, applied to special surfaces, devices for coating liquids on surfaces, coatings, etc., can solve the problems of complex operation and unenvironmental protection, achieve simple operation, improve hydrophobicity, and overcome complex operation. and not environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

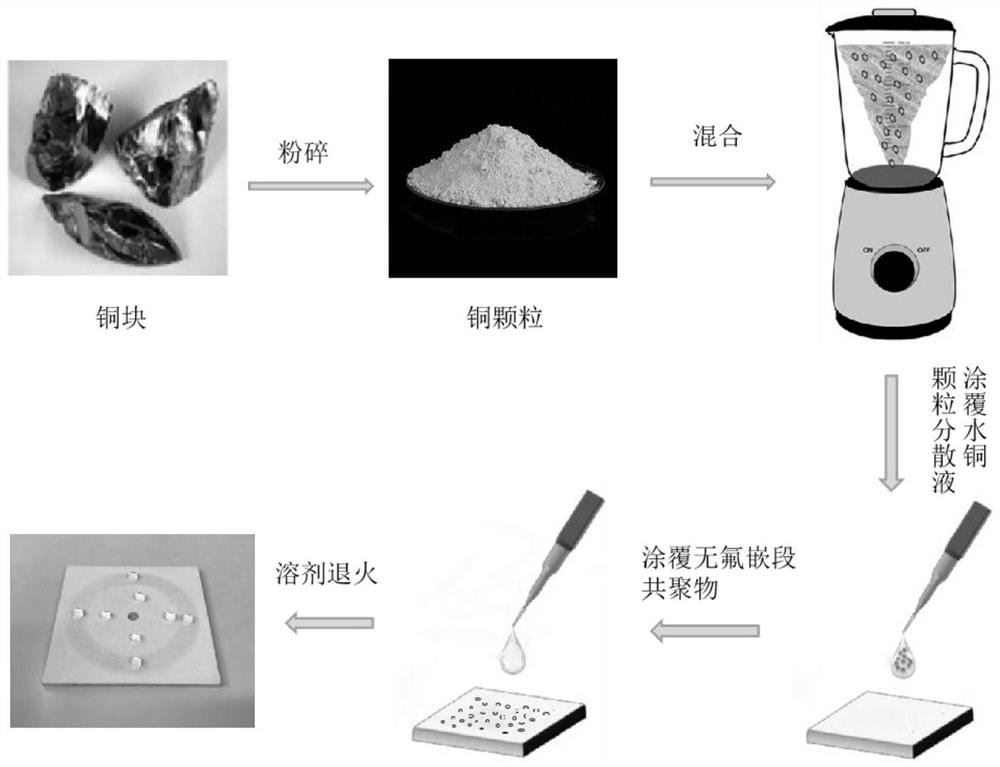

[0027] The invention provides a method for preparing a fluorine-free superhydrophobic surface, comprising the following steps:

[0028] (1) mixing the solid particles with a solvent to obtain a dispersion of the solid particles; the concentration of the solid particles in the dispersion is 0.3 to 0.5 g / mL; the particle size distribution of the solid particles in the dispersion is 200 nm to 10 μm; The solid particles include metal particles or inorganic oxide particles;

[0029] (2) Coating the dispersion in the step (1) on the surface of the substrate and drying to obtain a surface containing solid particles; the distribution density of the solid particles in the surface containing solid particles is 10000 to 20000 / mm 2 ;

[0030] (3) Coating the fluorine-free block copolymer solution on the surface containing solid particles obtained in the step (2), and then annealing to obtain a fluorine-free super-hydrophobic surface.

[0031] The invention mixes solid particles with a s...

Embodiment 1

[0071] (1) Use the MQW series jet mill (setting speed: 10000r / min, crushing time: 0.5h) to crush the copper block into copper particles with a particle size of 200nm-20μm, then put 5g of copper particles and 1000mL of deionized water into the Mixer, adjust the speed of the mixer to 1000r / min, stir for 0.5h, then stand still for 5s, take the upper suspension and add deionized water, and then repeat the above operation several times, so that the upper suspension only contains copper particles with a particle size of 200nm to 1μm. Add deionized water to the obtained upper layer suspension containing copper particles to adjust the concentration to 0.3 g / mL to obtain an aqueous dispersion of copper particles.

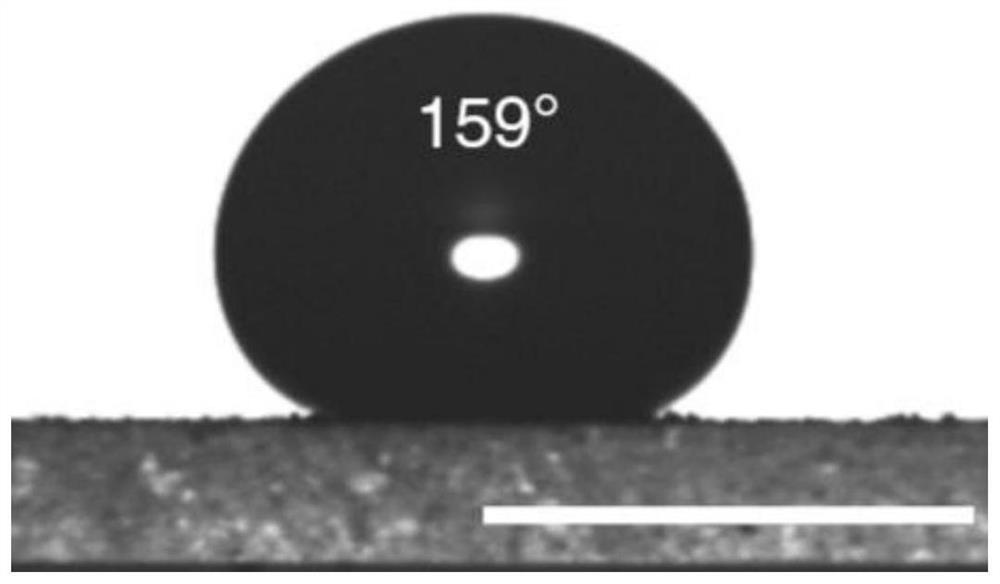

[0072] (2) Spin-coat the aqueous dispersion of copper particles obtained in step (1) onto the surface of the glass substrate (the rotating speed of the spin-coating is set to be 2000r / min, and the time of the spin-coating is 30s), then process at 150°C for 2h and dry, Form a...

Embodiment 2

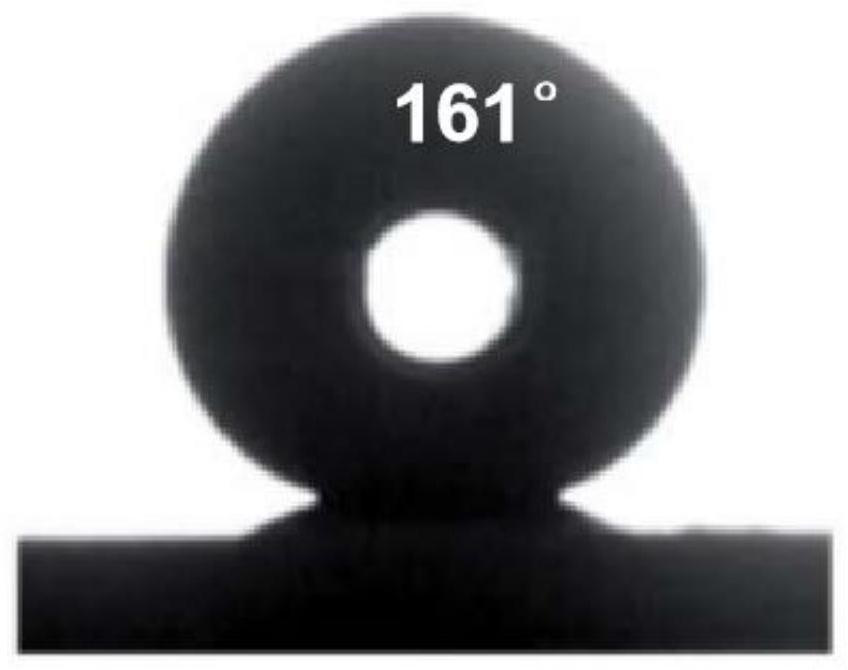

[0080] (1) Mix 3g of 200nm-10um aluminum particles with 100mL of deionized water, put them into a mixer, adjust the speed of the mixer to 1000r / min, and stir for 0.5h to obtain an aqueous dispersion of aluminum particles with a concentration of 0.3g / mL.

[0081] (2) Spin-coat the aqueous dispersion of aluminum particles obtained in step (1) onto the surface of the glass substrate (set the spin-coating speed to be 2000r / min, and the spin-coating time to be 30s), then treat and dry at 150°C for 2h, Form the surface containing aluminum particles, wherein the distribution density of aluminum particles on the surface containing aluminum particles is 11000-16000 / mm 2 .

[0082] (3) The surface of the aluminum-containing particles obtained in step (2) is spin-coated with MH-b-PS with a thickness of 40 μm (the speed of spin coating is 1500r / min, and the time of spin coating is 30s), and then using tetrahydrofuran at 25°C , annealed in solvent for 10h to obtain a superhydrophobic surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com