Alkylation reaction system and its supporting alkylation reaction process

A technology of alkylation reaction and alkylation reactor, which is applied in the field of alkylation reaction system device, high-efficiency alkylation reaction process method and alkylation reaction system. Equal issues to achieve the effect of avoiding adverse effects, improving product quality, and reducing the proportion of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

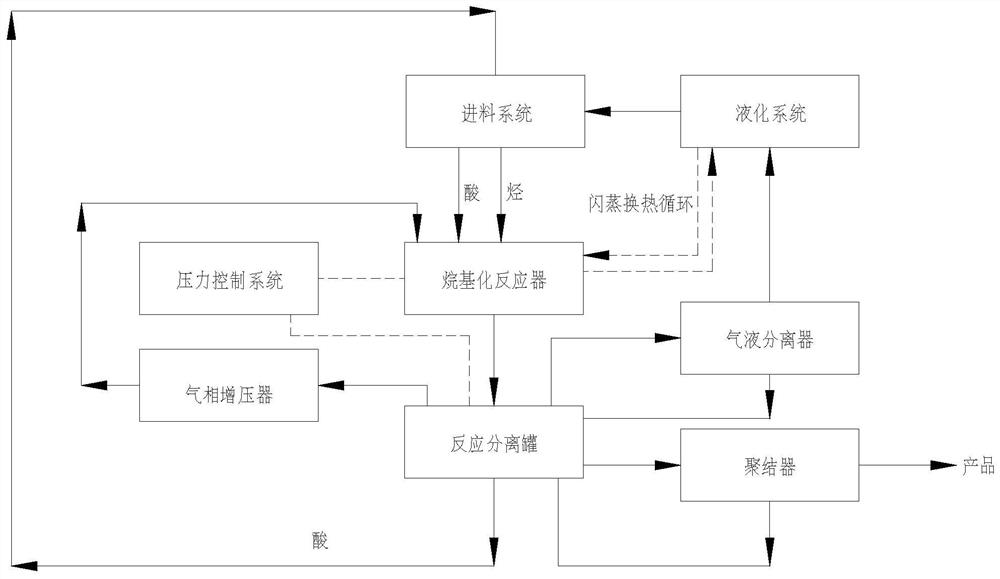

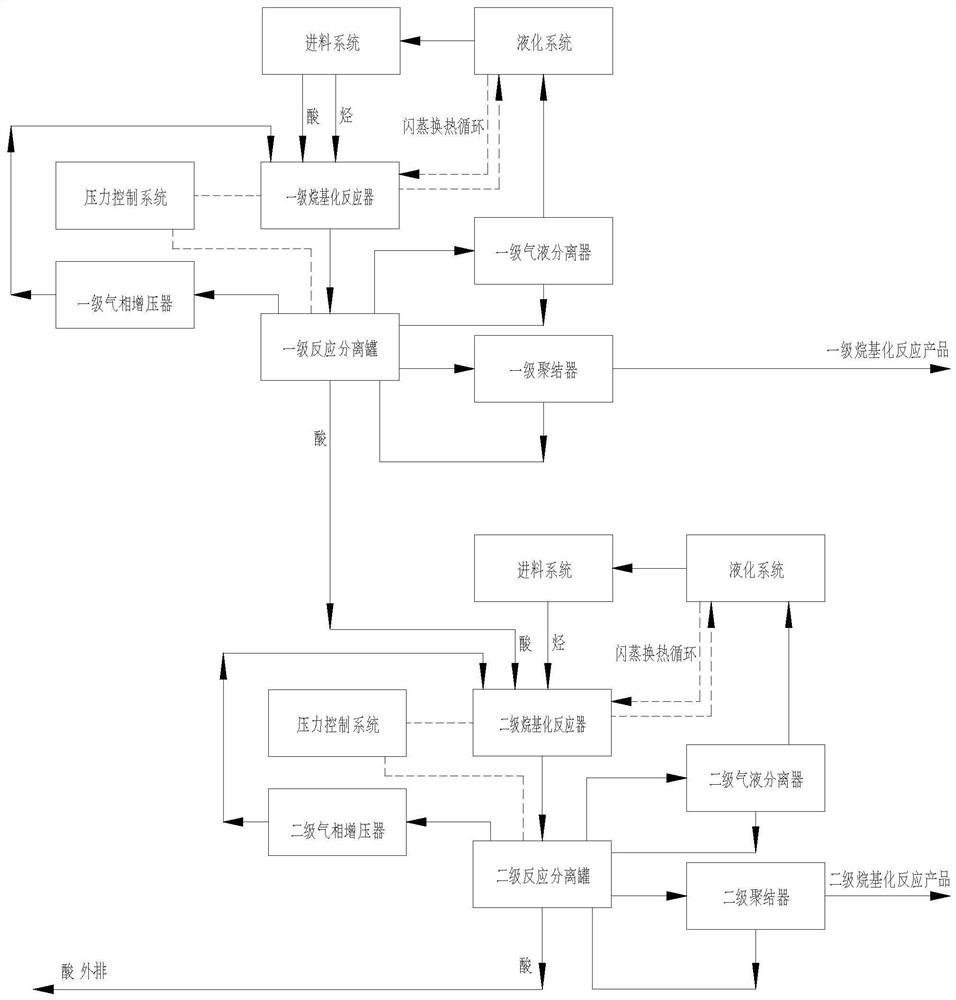

Method used

Image

Examples

Embodiment 1

The mixture of hydrocarbons, the composition of C3-C5 olefins is shown in Table 1 below:

Table 1

[0109]

[0110]

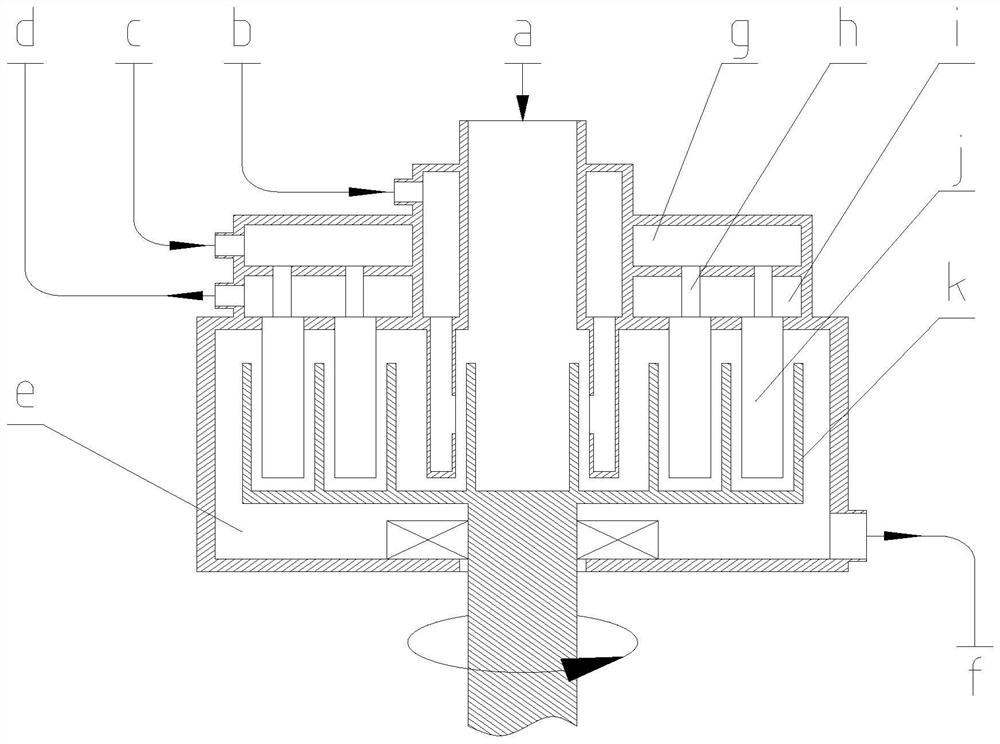

[0111] The feed ratio of maintaining the acid-hydrocarbon ratio of 0.9:1 is passed through the feed port of the alkylation reactor with 95 wt% sulfuric acid, respectively,

It is sprayed into the cavity of the alkylation reactor, mixed at a high speed under the action of the high-speed rotating rotor, and sent to the shell under the action of centrifugal force.

body movement. During this process, the mixed material is affected by the centrifugal force field and is disturbed by the high-speed shearing of the stator and rotor layer by layer.

Mixing and redistribution occur many times, and the dispersed form is very small droplets or very thin liquid films. When the reaction temperature of the system is 0 °C, the reaction

When the pressure system is controlled at 0.37MPa, part of the hydrocarbons in the droplets or liquid film flashes, taking away the heat of ...

Embodiment 2

[0123] The feed system adopts a volume concentration of 30.77% propane, 61.53% isobutane and 7.70% C3-C5 olefins

[0128] The RON value of the alkylation reaction product obtained by this process is 100.6.

Embodiment 3

[0131] The feed system adopts a volume concentration of 30.77% propane, 61.53% isobutane and 7.70% C3-C5 olefins

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com