A method and device for preparing monoglyceride based on hydrodynamic cavitation enhancement

A technology of hydrodynamic cavitation and monoglyceride, applied in chemical instruments and methods, transportation and packaging, chemical/physical/physicochemical processes, etc., can solve problems such as high viscosity and surface tension, decreased operational safety, and increased processing difficulty problem, to achieve the effect of avoiding high temperature oxidation, improving cavitation strength and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

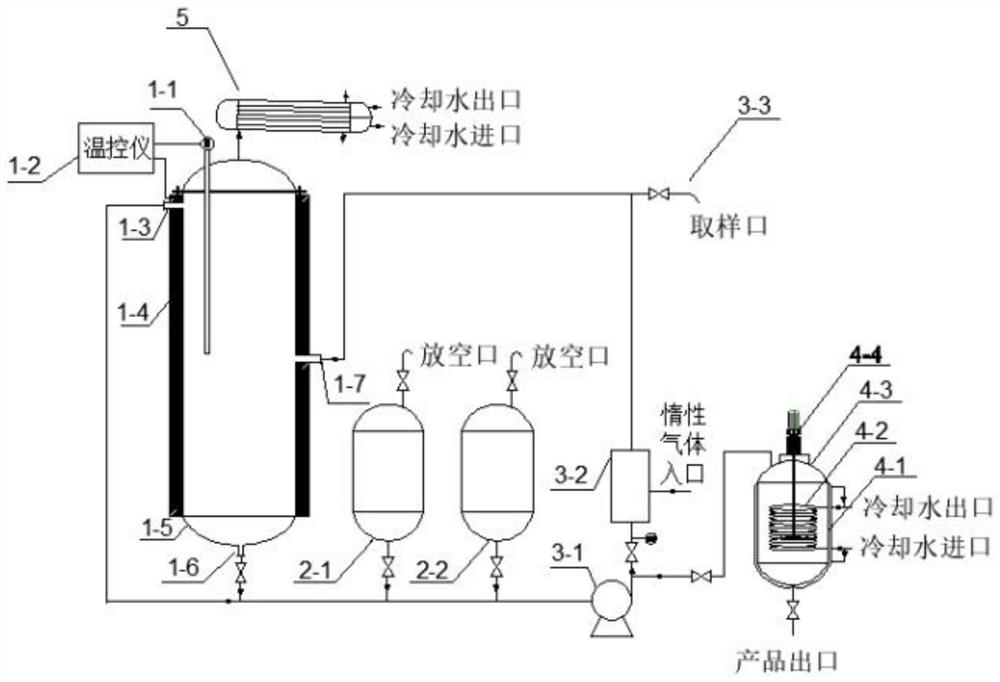

[0036] Example: Control Figure 1-3

[0037] A device for preparing monoglyceride based on hydrodynamic cavitation strengthening comprises a reaction kettle 1-5, a cavitation part, a raw material oil storage tank 2-1, a glycerol storage tank 2-2 and a quenching system. The tops of the raw oil storage tank 2-1 and the glycerin storage tank 2-2 are provided with vents and corresponding venting valves, and the bottoms of the raw oil storage tank 2-1 and the glycerin storage tank 2-2 are provided with outlets and corresponding discharges valve.

[0038] The outer side of the reaction kettle 1-5 is covered with an electric heating jacket 1-4, a thermometer 1-1 is inserted in the reaction kettle 1-5, and the temperature measurement point of the thermometer 1-1 is located in the inner part of the reaction kettle 1-5. The middle part of the interior; the thermometer 1-1 is connected to the temperature controller 1-2, the temperature controller 1-2 is connected to the electric heatin...

Embodiment 1

[0064] Monoglycerides were prepared by conventional mechanical stirring:

[0065] Soybean oil and glycerol were added to the reaction kettle, and the molar ratio of glycerol and soybean oil was 5:1, and the reaction was carried out under stirring, the stirring speed was 300r / min, and the reaction temperature was 250°C. During the reaction process, the content of monoglycerides generated by the reaction in the reaction mixture was monitored in real time, and the results were as follows Figure 4 shown.

Embodiment 2

[0067] Monoglycerides were prepared by conventional mechanical stirring:

[0068] Add soybean oil, glycerol and MgO powder catalyst (the mesh number of MgO powder is more than 200 meshes) in the reactor, the molar ratio of glycerol and soybean oil is 5:1, and the quality of MgO powder catalyst is the quality of soybean oil. 1.0wt%, the reaction is carried out under stirring, the stirring speed is 300r / min, and the reaction temperature is 250°C. During the reaction process, the content of monoglycerides generated by the reaction in the reaction mixture was monitored in real time, and the results were as follows Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com