Enteric coating material and its preparation method and enteric products

An enteric coating material and coating material technology are applied in the coating of sugar-coated pills, pharmaceutical formulas, and food, and can solve the problems of high weight gain rate, low production efficiency, and increased production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

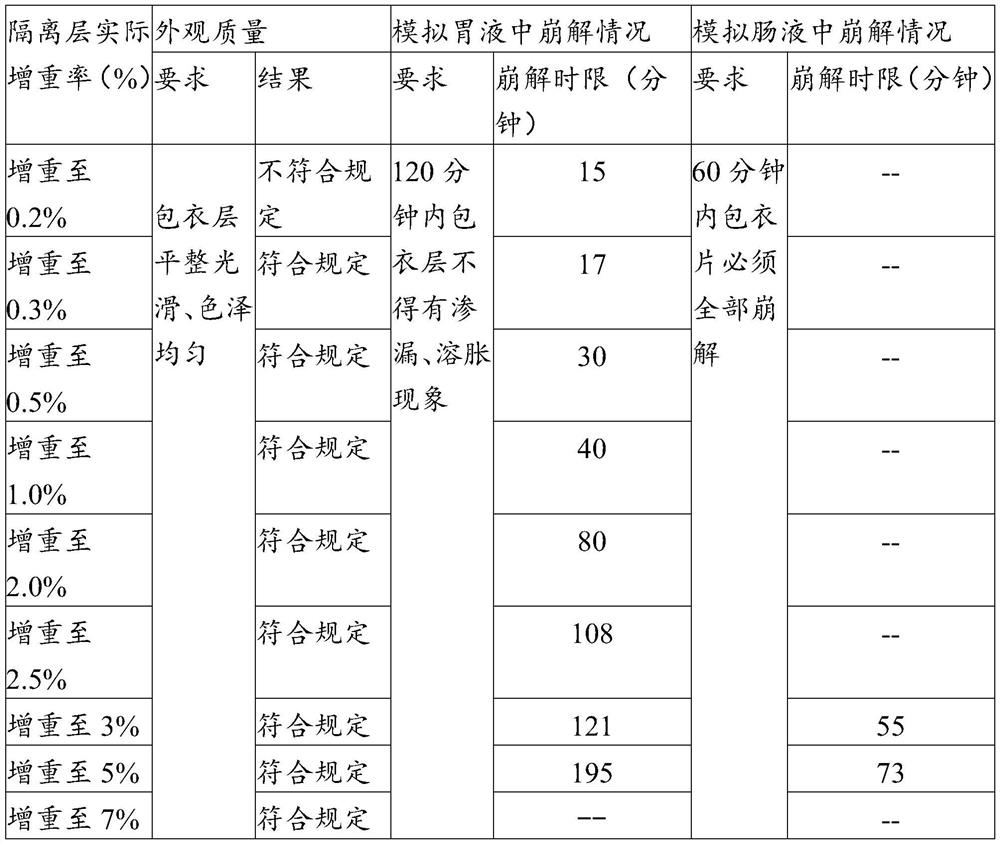

[0026] Embodiment 1: Selection experiment of coating material of isolation layer

[0027] 1. Prepare five kinds of isolation layer coating materials according to the following prescriptions:

[0028] Prescription 1: 1.5 parts by weight of hydroxypropyl methylcellulose, 3 parts by weight of polyacrylic resin II, 2 parts by weight of polyacrylic resin III, 0.5 parts by weight of talcum powder, and 3 parts by weight of polyethylene glycol, dissolved in 80v / v% ethanol solution 90 parts by weight, standby.

[0029] Prescription 2: 4 parts by weight of shellac, 0.5 parts by weight of hydroxypropyl methylcellulose, 2 parts by weight of magnesium stearate, 7 parts by weight of polyethylene glycol, dissolved in 120 parts by weight of 80v / v% ethanol solution, and set aside.

[0030] Prescription 3: 4 parts by weight of corn protein, 0.5 parts by weight of hydroxypropyl methylcellulose, 2 parts by weight of magnesium stearate, 7 parts by weight of polyethylene glycol, dissolved in 120...

Embodiment 2

[0053] Example 2: Experiment on selection of enteric outer coating material

[0054] 1. Formula composition and dosage of coated vegetarian tablet (pueraria tuckahoe pressed tablet candy): 0.5kg kudzu root powder, 0.5kg poria cocos powder, 0.2kg medlar powder, 5kg sodium bicarbonate, Potassium citrate 1kg, xylitol 1.6kg, corn starch 1.1kg, magnesium stearate 0.1kg. Accurately weigh the above-mentioned ingredients in the formula, and go through processes such as granulation, drying, granulation and general blending, and tabletting to obtain a plain tablet with a specification of 0.5 g for future use.

[0055] 2. Prepare the coating material of the isolation layer according to the following formula: 4 parts by weight of shellac, 0.5 parts by weight of hydroxypropyl methylcellulose, 2 parts by weight of magnesium stearate, 7 parts by weight of polyethylene glycol, dissolved in 80v / 120 parts by weight of v% ethanol, for subsequent use.

[0056] 3. Prepare three kinds of enter...

Embodiment 3

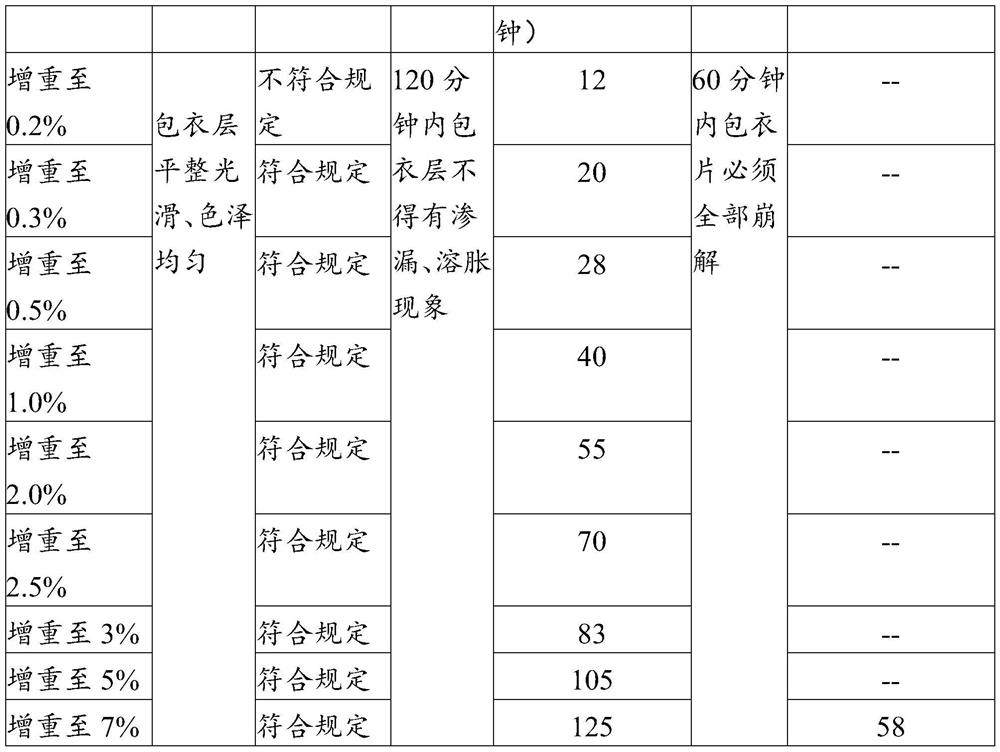

[0110] Embodiment 3: the selection experiment of the consumption of parameter in the coating material of isolation layer

[0111] 1. Formula composition and dosage of coated vegetarian tablet (pueraria tuckahoe pressed tablet candy): 0.5kg kudzu root powder, 0.5kg poria cocos powder, 0.2kg medlar powder, 5kg sodium bicarbonate, Potassium citrate 1kg, xylitol 1.6kg, corn starch 1.1kg, magnesium stearate 0.1kg. Accurately weigh the above-mentioned ingredients in the formula, and go through processes such as granulation, drying, granulation and general blending, and tabletting to obtain a plain tablet with a specification of 0.5 g for future use.

[0112] 2. Prepare three kinds of isolation layer coating materials according to the following formula:

[0113] Formula 1: 2 parts by weight of shellac, 0.3 parts by weight of hydroxypropyl methylcellulose, 0.2 parts by weight of magnesium stearate, 4 parts by weight of polyethylene glycol, and 60 parts by weight of 80v / v% ethanol s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com