Optical film, polarizing plate, and liquid crystal display device

A technology of optical film and organic particles, which is applied in the direction of optics, polarizing elements, optical elements, etc., can solve problems such as insufficient improvement of adhesion, difficulty in adhesion resistance, and increased haze of optical films, achieving excellent adhesion resistance, Excellent effect of transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0270] "The Production of Optical Film 1"

[0271] [Production of Organic Microparticles 1]

[0272] 200 mass parts of deionized water and 0.6 mass parts of sodium lauryl sulfate (SLS) are charged into a glass reactor equipped with a thermometer, a reflux condenser, a nitrogen inlet pipe, and agitator, and heated to 0.8 parts by mass of ammonium persulfate was added to the obtained aqueous solution at 80 to 85° C. while stirring.

[0273] Into the obtained aqueous solution, 10 parts by mass of styrene (St), 50 parts by mass of methyl methacrylate (MMA), and 20 parts by mass of divinylbenzene (DVB) were further added dropwise over 1 hour, and then, the obtained mixed The solution was stirred for 1 hour to obtain an emulsion. The obtained emulsion was dried by spray drying to obtain organic fine particles 1 .

[0274] [Preparation of Microparticle Dispersion 1]

[0275] After stirring and mixing 3 parts by mass of organic fine particles 1 and 97 parts by mass of methylene ch...

Embodiment 2

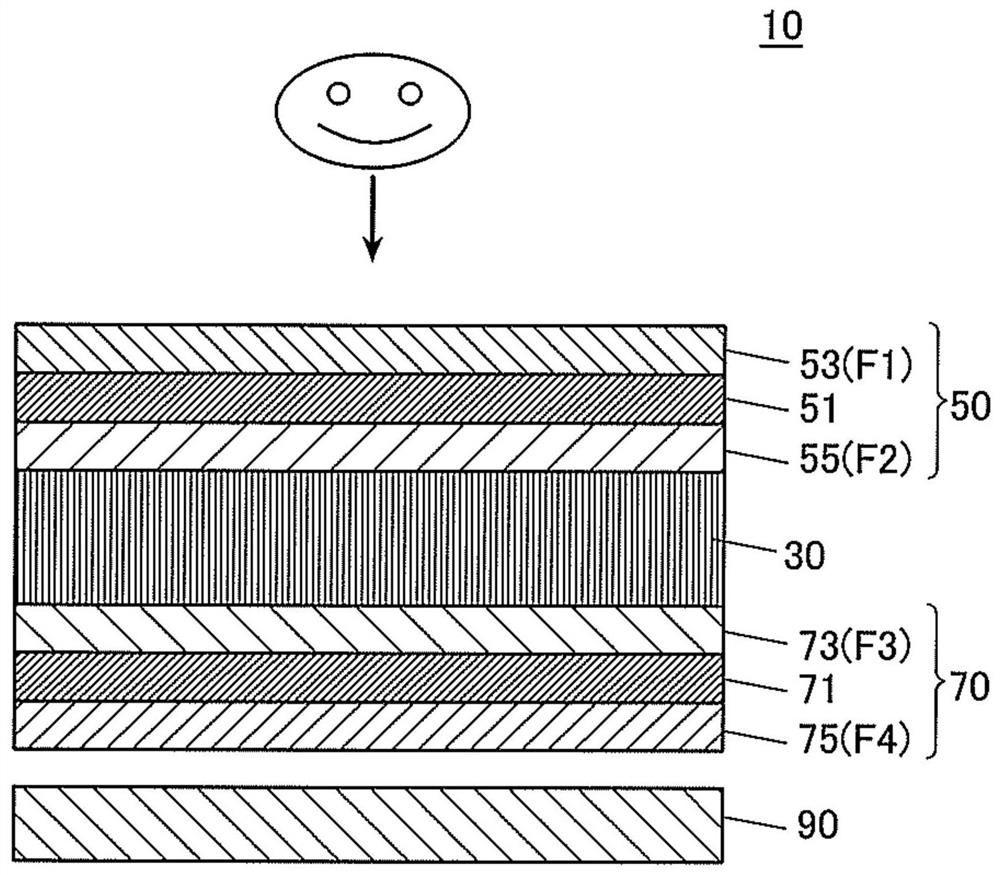

[0327] 3. Fabrication of Polarizers

[0328]

[0329] A polyvinyl alcohol film having a thickness of 70 µm was swelled with water at 35°C. The obtained film was immersed for 60 seconds in an aqueous solution consisting of 0.075 g of iodine, 5 g of potassium iodide, and 100 g of water, and further immersed in a 45° C. aqueous solution of 3 g of potassium iodide, 7.5 g of boric acid, and 100 g of water. The obtained film was uniaxially stretched under conditions of a stretching temperature of 55° C. and a stretching ratio of 5 times. This uniaxially stretched film was washed with water and then dried to obtain a 20 μm thick polarizer.

[0330]

[0331] (Preparation of active energy ray curable adhesive)

[0332] After mixing the following components, defoaming was performed to prepare an active energy ray-curable adhesive. In addition, triarylsulfonium hexafluorophosphate was mixed as 50% propylene carbonate solution, and the solid content amount of triarylsulfonium hexaf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average primary particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com