A method for staged fracturing with cryogenic fluid in horizontal wells

A low-temperature fluid, horizontal well technology, applied in the fields of fluid extraction, drilling equipment and methods, directional drilling, etc., can solve the problems of water waste, high energy consumption, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below.

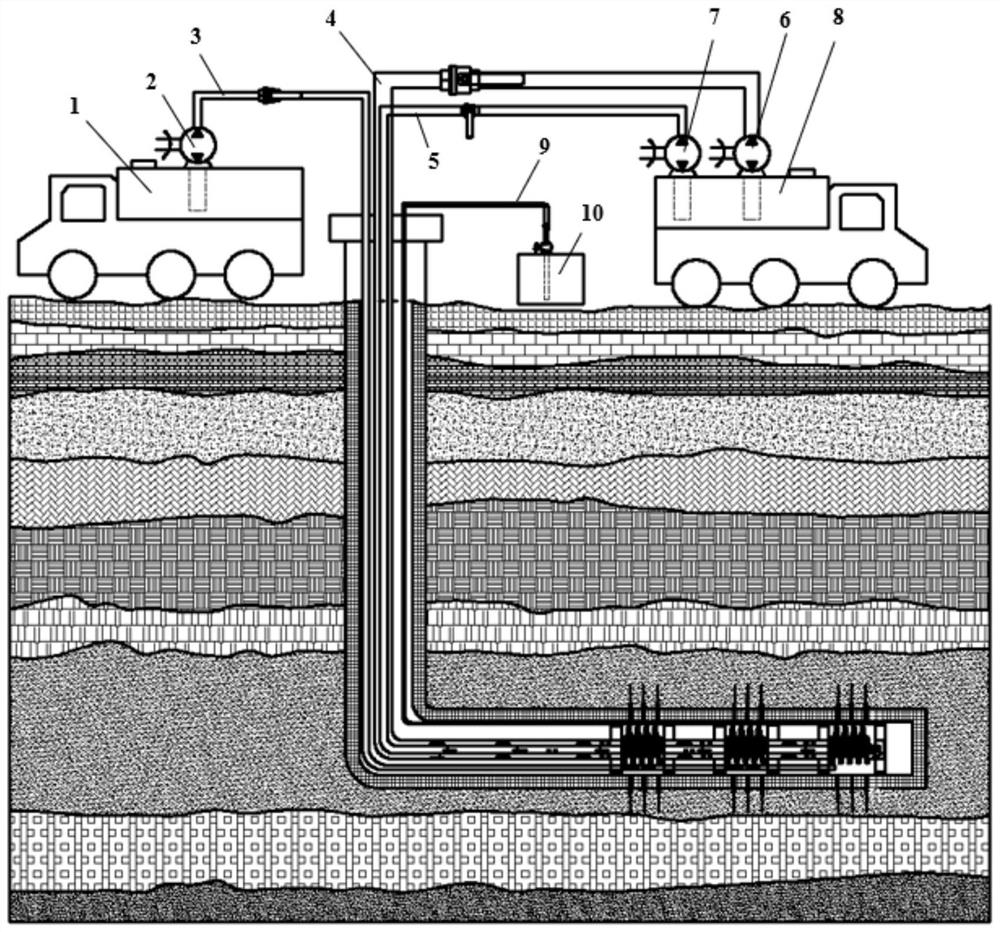

[0020] Such as Figure 1 to Figure 2 Shown, the concrete steps of the present invention are:

[0021] A. Drilling from the ground first, extend the perforating gun into the horizontal drilling, and prefabricate three fractured areas at equal intervals along the direction perpendicular to the horizontal drilling with the axis of the horizontal drilling as the center, namely the first fractured area and the second fractured area. fracture zone and third fracture zone;

[0022] B, supercooled water pipe 3 is set, and supercooled water pipe 3 is divided into horizontal section and vertical section, and three groups of rubber sealing devices are housed in the horizontal section of supercooled water pipe 3, are respectively the first rubber sealing device 20, the second rubber sealing device Blocking device and the third rubber blocking device, each group of rubber blocking devices is composed of two uncharged water pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com