Fabricated wall mounting plate structure

A mounting plate and assembly technology, applied in building construction, covering/lining, construction, etc., can solve the problems of waste of materials, troublesome replacement of soft bags, complicated assembly of wall mounting plates, etc., so that it is not easy to fall off and easy to assemble. , The effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

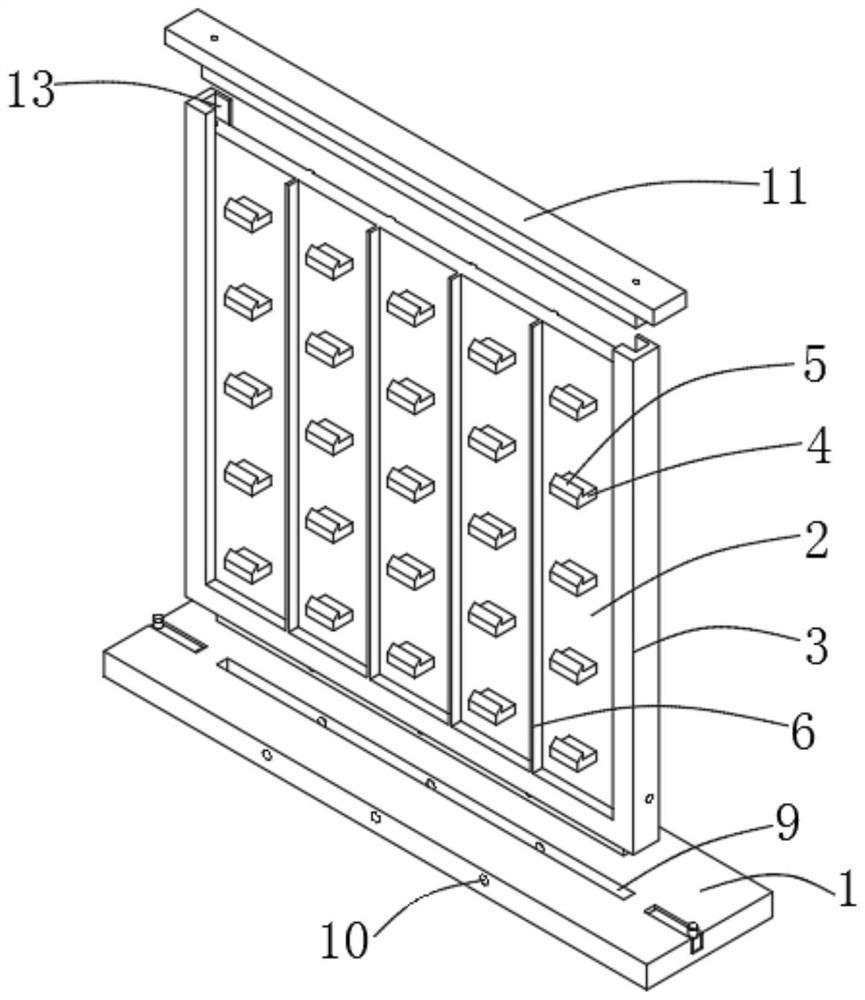

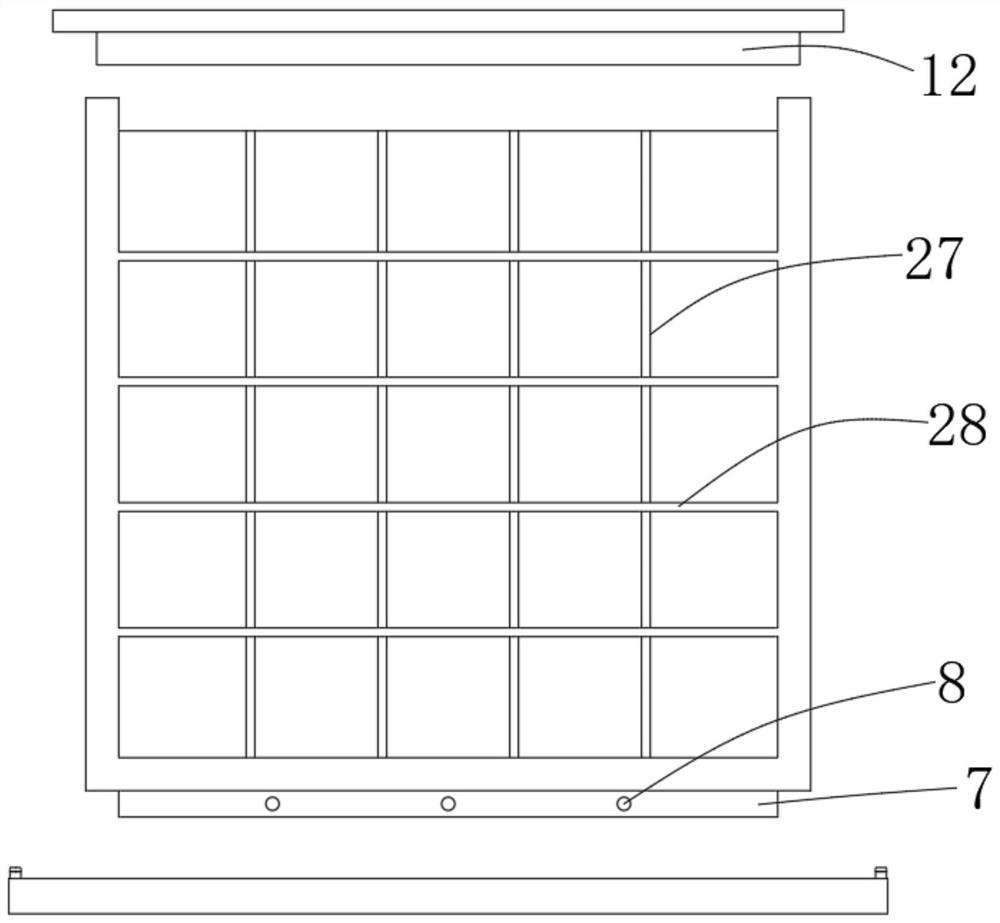

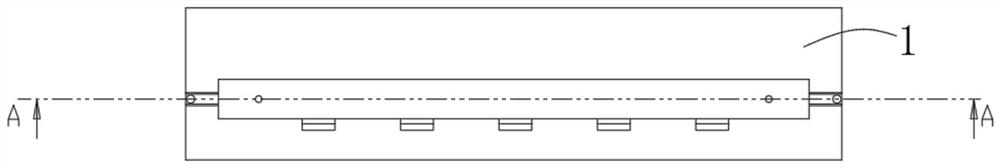

[0039] Embodiment one: if Figure 1-7 The present embodiment shown is a method of using a prefabricated wall mounting plate structure: insert the first inserting plate 7 into the first plate groove 9, and fix it with bolts between the first adapting hole 10 and the first screw hole 8 , rotate the rotating column 18, insert the fixed column 19 into the fixing groove 21, the first magnet 20 and the second magnet 22 attract each other; install the soft bag 23, insert the card column 4 into the card slot 24, and then insert the protrusion 5 into the groove 25 , the soft bag 23 is covered with the wallboard 2, and the partition plate 6 separates the soft bag 23 to enhance the stability of the soft bag 23; then insert the second board 12 into the second plate groove 13, and connect the second screw hole through the bolt 14 is fixed with the second adapting hole 15; the vertical bar 27 and the cross bar 28 play the role of strengthening structure; when the soft bag 23 is damaged, rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com