SnOx/BiVO4 electrode, preparation method thereof and application of SnOx/BiVO4 electrode to photoelectrocatalytic hydrogen peroxide synthesis

An electrode, stannous chloride technology, applied in electrodes, electrolysis components, electrolysis processes, etc., can solve the problems of low hydrogen peroxide yield and low Faradaic efficiency, and achieve the effects of increasing production, improving effective separation, and inhibiting recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

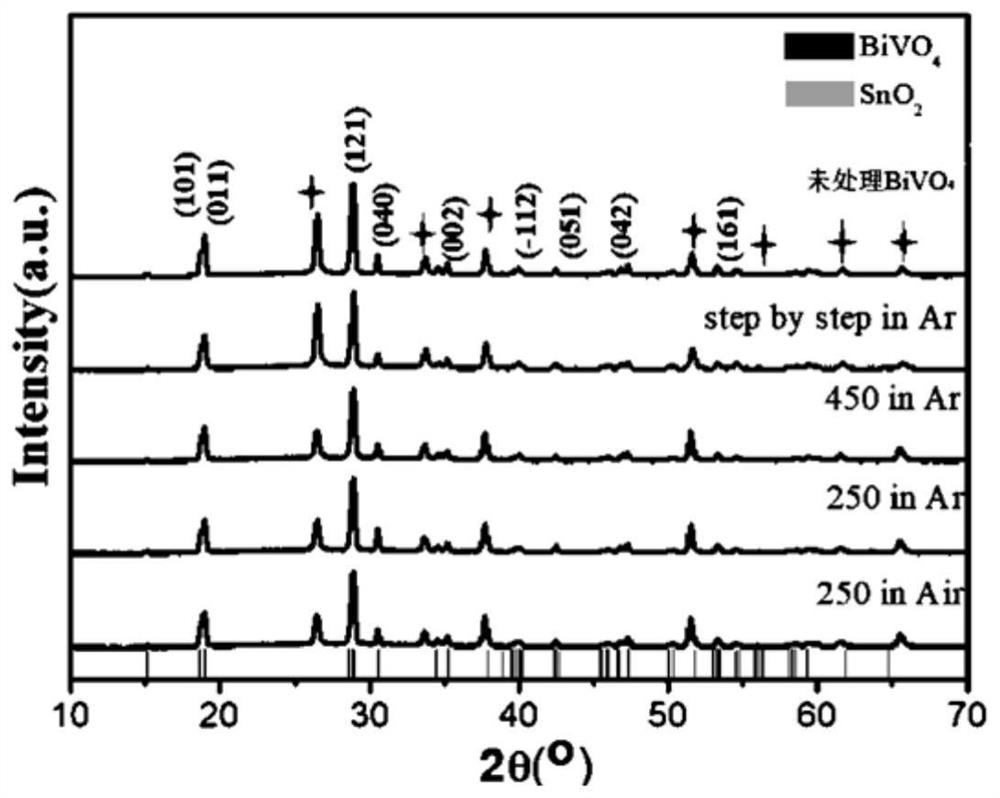

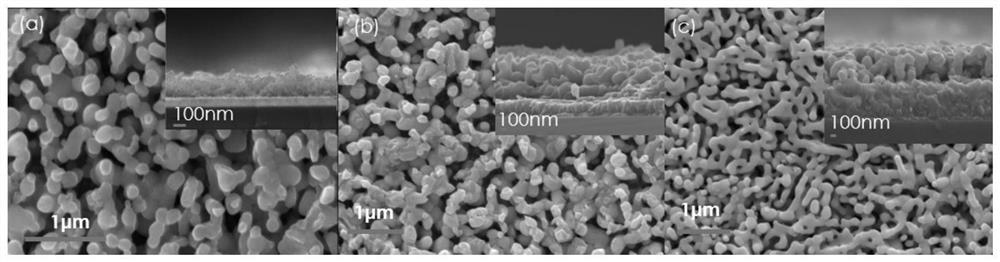

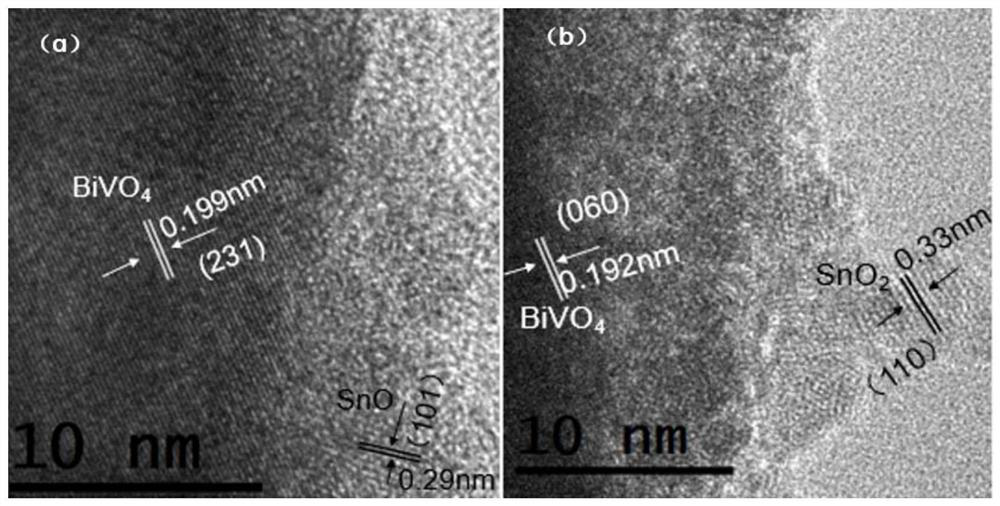

[0029] Weigh 0.1932g of stannous chloride and dissolve it in a mixed solution of 10ml ethylene glycol methyl ether and 0.2ml acetylacetone, and ultrasonicate for 30min after dissolving. The solution was left to stand for 12 h after sonication. Spin-coat the standing solution at a speed of 500r.p.m for 5s first, then spin-coat at a speed of 2000r.p.m for 35s, and then spin-coat the bismuth vanadate surface step by step. The prepared sample is placed in a tube furnace and annealed under an argon atmosphere. The annealing temperature is 250°C, and the annealing time is 30 minutes. After natural cooling, the SnO can be obtained by taking it out. x / BiVO 4 electrode. In the photoelectrochemical test, the CHI660E electrochemical workstation was used, the Ag / AgCl electrode was used as the reference electrode, and the Pt was used as the counter electrode to prepare the SnO x / BiVO 4 The electrode is the working electrode, in 1M NaHCO 3 The photoelectrocatalytic synthesis of hydro...

Embodiment 2

[0035] Weigh 0.1932g of stannous chloride and dissolve it in a mixed solution of 10ml ethylene glycol methyl ether and 0.2ml acetylacetone, and ultrasonicate for 30min after dissolving. The solution was left to stand for 12 h after sonication. Spin-coat the standing solution at a speed of 500r.p.m for 5s first, then spin-coat at a speed of 2000r.p.m for 35s, and then spin-coat the bismuth vanadate surface step by step. The prepared sample is placed in a tube furnace and annealed under an argon atmosphere. The annealing temperature is 450°C, and the annealing time is 30 minutes. After natural cooling, the SnO can be obtained by taking it out. x / BiVO 4 catalyst of light. In the photoelectrochemical test, the CHI660E electrochemical workstation was used, the Ag / AgCl electrode was used as the reference electrode, and the Pt was used as the counter electrode to prepare the SnO x / BiVO 4 The electrode is the working electrode, in 1M NaHCO 3 The photoelectrocatalytic synthesis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com