Ferrite low-temperature steel forging and low-temperature cryogenic preparation method thereof

A low-temperature steel and ferrite technology, applied in the field of alloy processing, can solve the problems of high energy consumption of liquid nitrogen cryogenic, low cryogenic temperature of liquid nitrogen, and increased production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

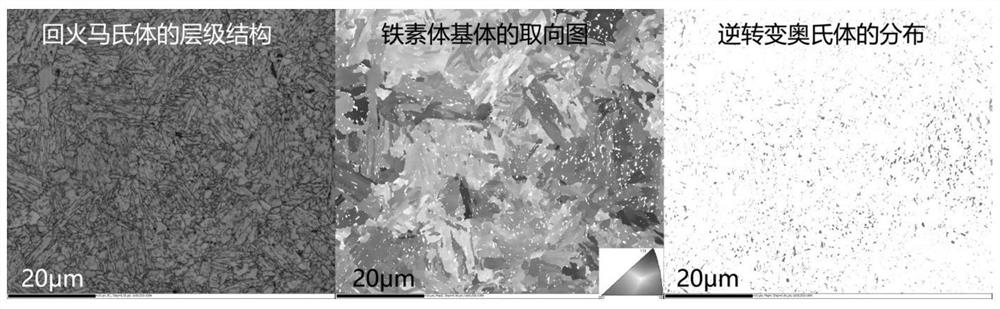

[0024] The invention provides a ferritic low-temperature steel forging and a low-temperature cryogenic preparation method thereof, comprising the following steps:

[0025] (1) performing homogenization annealing after forging the billet to obtain an annealed forging;

[0026] (2) performing quenching and tempering treatment for the first time on the annealed forging obtained in the step (1) successively to obtain a tempered forging;

[0027] (3) subjecting the tempered forgings obtained in the step (2) to sequentially sub-stage cryogenic treatment at -70 to -85°C, -95 to -105°C and -115 to -130°C to obtain cryogenic forgings;

[0028] (4) The cryogenic forging obtained in step (3) is subjected to a second tempering treatment to obtain a ferritic low-temperature steel forging.

[0029] The invention performs homogenization annealing after forging and molding the billet to obtain an annealed forging.

[0030] In the present invention, the starting temperature of the forging is...

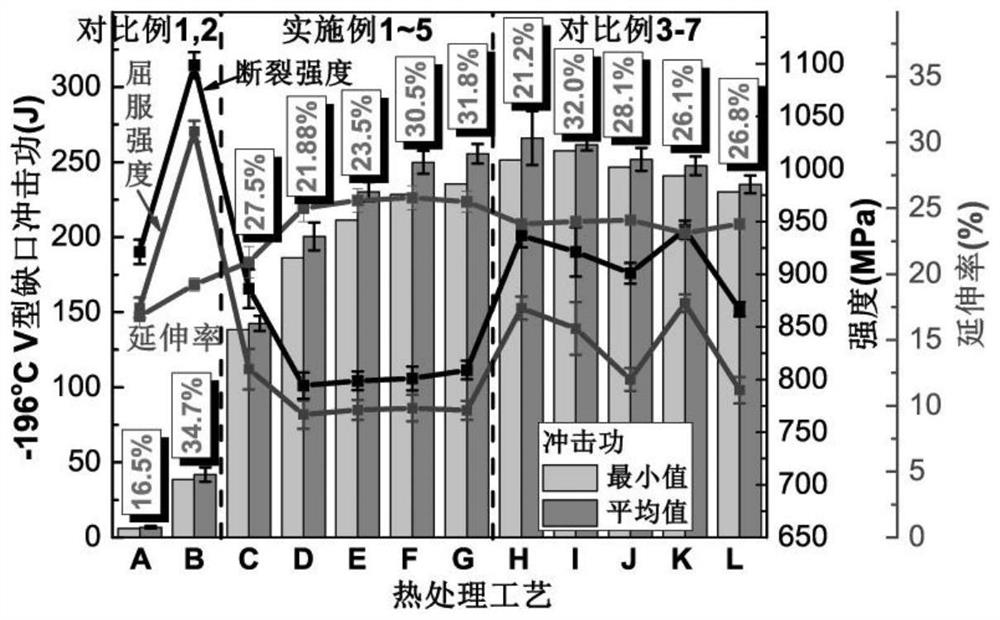

Embodiment 1

[0054] In terms of weight percentage, the composition of ferritic low-temperature steel forgings is: 0.03% C, 0.71% Mn, 0.11% Si, 9.35% Ni, 0.80% Cu and the balance iron.

[0055] The preparation method of the ferritic low-temperature steel forging is as follows:

[0056] (1) After soaking the billet at 1110°C, it is forged and formed. The final forging temperature is 750°C, the cumulative compression ratio is 6, air-cooled to room temperature, then heated to 1110°C and kept for 24 hours, homogenized annealed, and air-cooled to room temperature to obtain Annealed forgings;

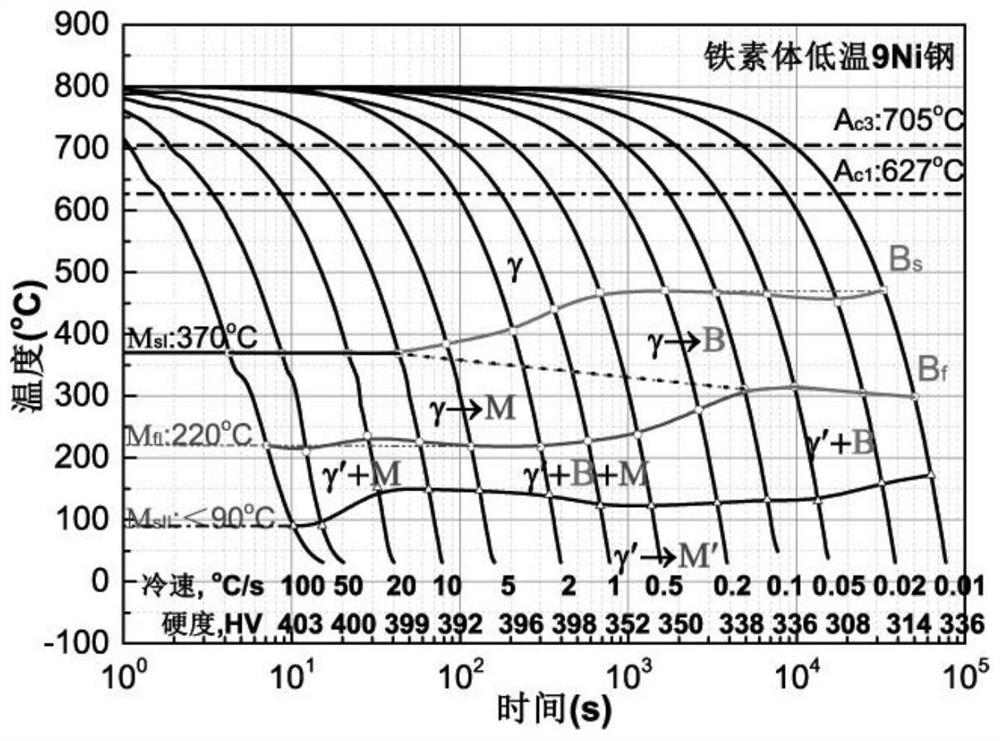

[0057] (2) Process the annealed forging obtained in the step (1), then raise the temperature to 830°C for heat preservation, and then perform quenching, and control the cooling rate of the core of the largest section of the forging to >0.05°C / s (or simulated by furnace cooling) , cooled to room temperature;

[0058] (3) The tempered forging obtained in the step (2) is subjected to cryogenic treatment at ...

Embodiment 2

[0063] In terms of weight percentage, the composition of ferritic low-temperature steel forgings is: 0.03% C, 0.71% Mn, 0.11% Si, 9.35% Ni, 0.80% Cu and the balance iron.

[0064] The preparation method of the ferritic low-temperature steel forging is as follows:

[0065] (1) After soaking the billet at 1110°C, it is forged and formed. The final forging temperature is 750°C, the cumulative compression ratio is 6, air-cooled to room temperature, then heated to 1110°C and kept for 24 hours, homogenized annealed, and air-cooled to room temperature to obtain Annealed forgings;

[0066] (2) Process the annealed forging obtained in the step (1), then raise the temperature to 830°C for heat preservation, and then perform quenching, and control the cooling rate of the core of the largest section of the forging to >0.05°C / s (or simulated by furnace cooling) , cooled to room temperature, then heated to 625°C for 4 hours for the first tempering, water cooled to room temperature;

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com