Water-coal-slurry prepared by using benzene extraction residual liquid and preparation method of water-coal-slurry

A technology for extracting raffinate and coal-water slurry, which is applied in the field of petrochemical industry, can solve the problems of low gasification reaction temperature and large waste water discharge, achieve high carbon conversion rate, reduce discharge, and avoid high oxygen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

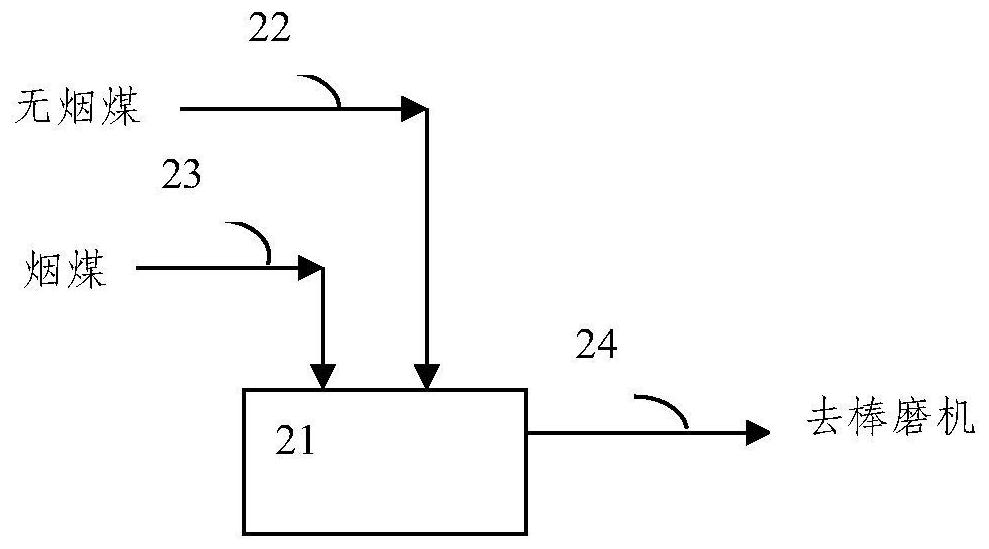

[0059] Such as Figure 1 to Figure 2 Shown, for the present invention utilizes the concrete embodiment that the coal-water slurry prepared by benzene extraction raffinate is applied to the gasification process, comprises the following steps:

[0060] 1) Preparation of mixed coal

[0061] The first flat belt 22 for anthracite and the second flat belt 23 for bituminous coal are sent to the coal blending device 21 according to a certain ratio to prepare mixed coal, and then sent to the rod mill 2 by the third flat belt 24 . The coal blending device is equipped with a belt scale, PLC control system, and an impeller-type coal feeder with adjustable speed. The weight mixing ratio between bituminous coal and anthracite is adjusted by PLC, and the mixed coal with ash content Aad8-20%, ash melting point 1300-1450 DEG C and internal water Mad less than 6% is prepared.

[0062] The bituminous coal is selected to use Shenyou 2# bituminous coal produced by Shenhua Company with low ash co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com