APET composite material and preparation method thereof, keyboard cover, electronic component tray and preparation method thereof

A technology of electronic components and composite materials, applied in the field of materials, can solve the problems of restricting applications and low transparency of APET keyboard covers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

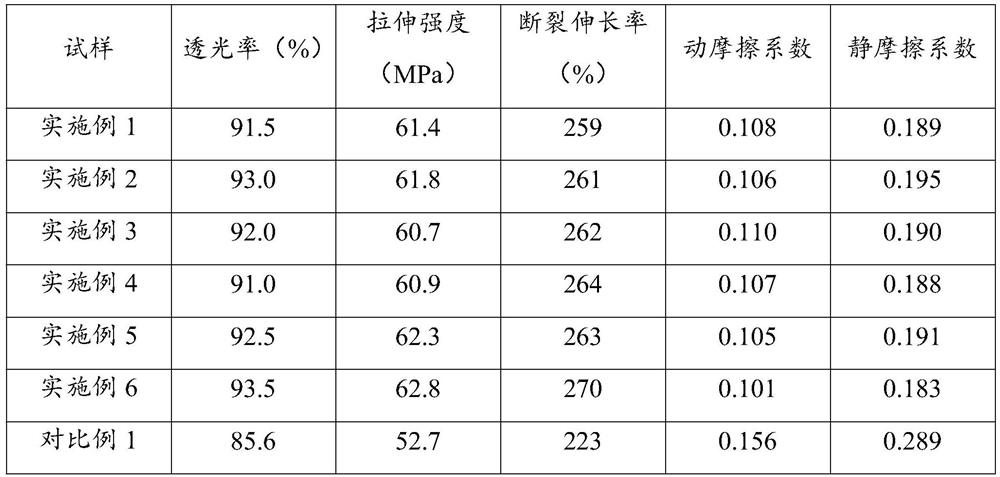

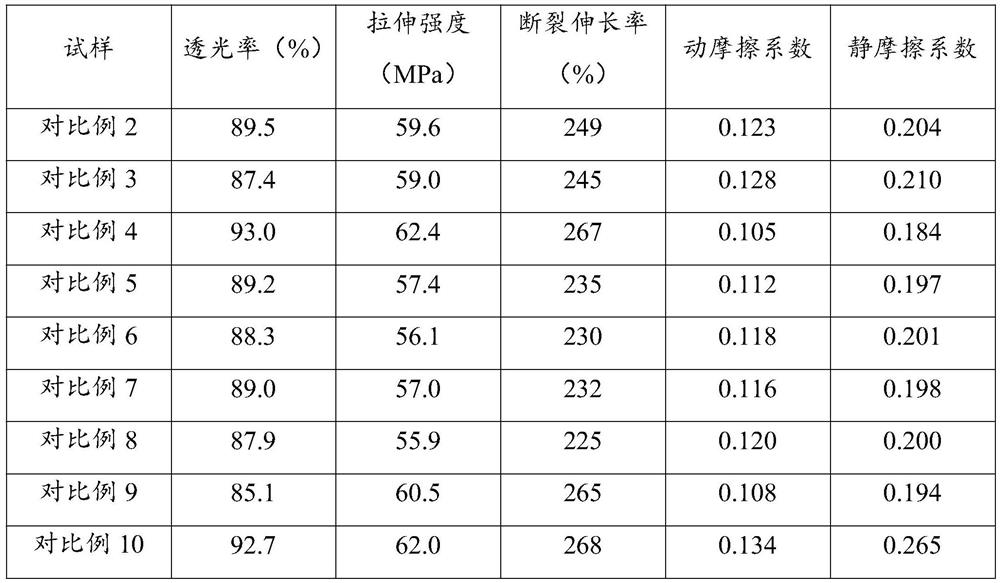

Examples

preparation example Construction

[0022] The embodiment of the present invention provides a method for preparing an APET composite material, comprising the following steps:

[0023] Step 101, weighing each component according to the following formula for later use: 100-150 parts of APET, 2-10 parts of PETG, 5-8 parts of modified loess, 2-7 parts of whitening agent and 1-3 parts of smoothing agent.

[0024] In a preferred embodiment of the present invention, the whitening agent is a mixture of titanium dioxide-coated calcium carbonate and vinyltriethylsilane. The slip agent is a mixture of any two of bio-based slip agent, erucamide slip agent or polyethylene wax.

[0025] The transparency of APET composites can be improved by adding the above-mentioned brightener; adding the above-mentioned smooth agent can not only assist the mixture to be extruded smoothly through the extruder, avoid clogging the die, improve production efficiency, and can give the product Excellent slip properties.

[0026] Step 102, ball ...

Embodiment 1

[0063] The preparation process of the APET composite material in the present embodiment is as follows:

[0064] Weigh each component according to the following formula for later use: 100 parts of APET, 2 parts of PETG, 5 parts of modified loess, 7 parts of whitening agent and slip agent (a mixture of bio-based slip agent and erucamide slip agent) 1 serving.

[0065] The APET is dried at 170° C. for 4 hours, so that the moisture content after drying is lower than 0.005%, and the dried APET is obtained.

[0066] The dried APET was ball milled and blended with PETG, modified loess, whitening agent and smooth agent to form a ball milled blend.

[0067] The temperature of the ball-milled blend was raised to 300° C. at a heating rate of 23° C. / min, and stirred for 60 min at a stirring rate of 1000 r / min to obtain a mixture.

[0068] The mixture is extruded through an extruder and flowed into a three-roll machine through a die for roll forming and cooling to obtain the APET composi...

Embodiment 2

[0070] The preparation process of the APET composite material in the present embodiment is as follows:

[0071] The components were weighed according to the following formula for later use: 120 parts of APET, 8 parts of PETG, 6 parts of modified loess, 5 parts of whitening agent and 3 parts of slip agent (a mixture of bio-based slip agent and polyethylene wax).

[0072] The APET is dried at 180° C. for 4 hours, so that the moisture content after drying is lower than 0.005%, and the dried APET is obtained.

[0073] The dried APET was ball milled and blended with PETG, modified loess, whitening agent and smooth agent to form a ball milled blend.

[0074] The temperature of the ball-milled blend was raised to 350° C. at a heating rate of 25° C. / min, and stirred for 30 min at a stirring rate of 1500 r / min to obtain a mixture.

[0075] The mixture is extruded through an extruder and flowed into a three-roll machine through a die for roll forming and cooling to obtain the APET comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com