Integrally poured building construction method

A construction method and house technology, which is applied in the direction of construction and building construction, can solve the problems of pouring formwork deformation and insufficient strength, and reduce the quality of house construction, so as to achieve the effects of reducing construction cost, reducing construction time, and reducing self-shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

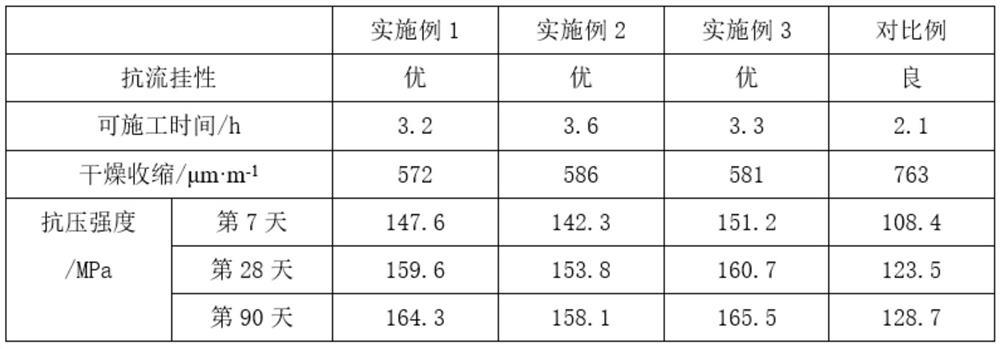

Embodiment 1

[0066] An integrated pouring building construction method, comprising the following steps:

[0067] S1. Clean up the construction site: According to the design of the construction drawings, circle the scope of the land to be constructed, and clean up the debris on the land to be constructed;

[0068] S2. Build the foundation: Determine the specific location and area of the building to be constructed, and mark it, first use excavators and loaders to mechanically excavate and level, and then use a road roller to compact the land at this location;

[0069] S3. Set up drainage: set up multiple drainage grooves near the foundation, and ensure smooth drainage to avoid rainwater soaking the foundation;

[0070] S4. Foundation construction: according to the design of the construction drawings, build a frame model of the building at the foundation;

[0071] S5. Building formwork: building a building formwork outside the frame model, and fixing the building formwork on the outside of...

Embodiment 2

[0122] An integrated pouring building construction method, comprising the following steps:

[0123] S1. Clean up the construction site: According to the design of the construction drawings, circle the scope of the land to be constructed, and clean up the debris on the land to be constructed;

[0124] S2. Build the foundation: Determine the specific location and area of the building to be constructed, and mark it, first use excavators and loaders to mechanically excavate and level, and then use a road roller to compact the land at this location;

[0125] S3. Set up drainage: set up multiple drainage grooves near the foundation, and ensure smooth drainage to avoid rainwater soaking the foundation;

[0126] S4. Foundation construction: according to the design of the construction drawings, build a frame model of the building at the foundation;

[0127] S5. Building formwork: building a building formwork outside the frame model, and fixing the building formwork on the outside of...

Embodiment 3

[0178] An integrated pouring building construction method, comprising the following steps:

[0179] S1. Clean up the construction site: According to the design of the construction drawings, circle the scope of the land to be constructed, and clean up the debris on the land to be constructed;

[0180] S2. Build the foundation: Determine the specific location and area of the building to be constructed, and mark it, first use excavators and loaders to mechanically excavate and level, and then use a road roller to compact the land at this location;

[0181] S3. Set up drainage: set up multiple drainage grooves near the foundation, and ensure smooth drainage to avoid rainwater soaking the foundation;

[0182] S4. Foundation construction: according to the design of the construction drawings, build a frame model of the building at the foundation;

[0183] S5. Building formwork: building a building formwork outside the frame model, and fixing the building formwork on the outside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com