Preparation method of fireproof glass

A fireproof glass and glass technology, which is applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve the problems of troublesome preparation of fireproof insulating glass, lack of transparency, lack of fireproof performance of fireproof glass, etc., and achieve good heat insulation effect and diffusion The effect of high speed and low thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

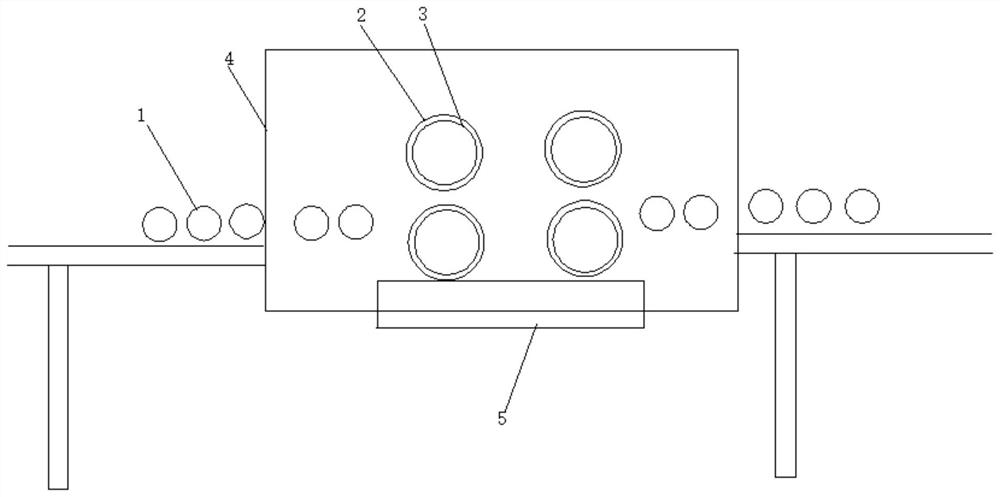

Image

Examples

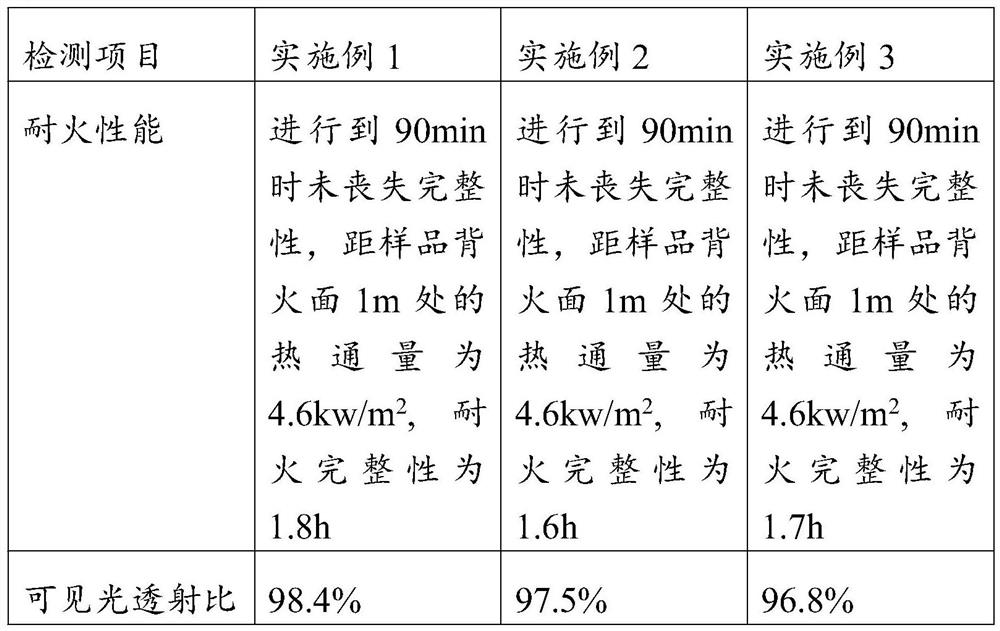

Embodiment 1

[0030] (1) Preparation of glass flakes: after first preparing the thin glass, take two thin slices of glass and clamp a transparent organic film in the middle to form a glass flake after bonding and fixing; the thickness of the thin glass is 2mm, and the organic film is smooth and transparent The film is clamped in the thin glass to discharge the air bubbles inside, and the two pieces of thin glass are bonded and reinforced with an inorganic adhesive around it; the inorganic adhesive is made of the following components in parts by weight: N-methylol 48 parts of acrylamide, 23 parts of aluminum oxide, 42 parts of sodium chloride, 12 parts of alum, 2 parts of absolute ethanol, and 1 part of ammonium persulfate. The inorganic adhesive is a silicate adhesive.

[0031] (2) Insulating glass molding: Take the two glass sheets prepared in step (1), use glass glue to seal the edges around the glass sheets to form a sealed insulating glass, and reserve an air outlet on the side, the edge...

Embodiment 2

[0036] (1) Preparation of glass flakes: after first preparing the thin glass, take two thin slices of glass and clamp a transparent organic film in the middle to bond and fix it to form a glass flake; the thickness of the thin glass is 4mm, and the organic film is smooth and transparent The film is clamped in the thin glass to discharge the air bubbles inside, and the two pieces of thin glass are bonded and reinforced with an inorganic adhesive around it; the inorganic adhesive is made of the following components in parts by weight: N-methylol 53 parts of acrylamide, 40 parts of aluminum oxide, 50 parts of sodium chloride, 20 parts of alum, 8 parts of absolute ethanol, and 3 parts of ammonium persulfate. The inorganic adhesive is a silicate adhesive.

[0037](2) Insulating glass molding: Take the two glass sheets prepared in step (1), use glass glue to seal the edges around the glass sheets to form a sealed insulating glass, and reserve an air outlet on the side, the edge seali...

Embodiment 3

[0042] (1) Preparation of glass flakes: after first preparing the thin glass, take two thin slices of glass and clamp a transparent organic film in the middle to bond and fix it to form a glass flake; the thickness of the thin glass is 3mm, and the organic film is smooth and transparent Film, which is clamped in the thin glass to discharge the air bubbles inside, and the two pieces of thin glass are bonded and strengthened with an inorganic adhesive around; the inorganic adhesive is made of the following components in parts by weight: N-methylol 50 parts of acrylamide, 30 parts of aluminum oxide, 45 parts of sodium chloride, 16 parts of alum, 6 parts of absolute ethanol, and 2 parts of ammonium persulfate. The inorganic adhesive is a silicate adhesive.

[0043] (2) Insulating glass molding: Take the two glass sheets prepared in step (1), use glass glue to seal the edges around the glass sheets to form a sealed insulating glass, and reserve an air outlet on the side, the edge se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com