Hybrid power vehicle driving system capable of governing speed by using motors during gear shifting

A hybrid vehicle and drive system technology, which is applied to the layout of multiple different prime movers of hybrid vehicles, motor vehicles, and general power plants, and can solve problems that affect driving comfort, fuel economy, and component damage. , to achieve the effect of simplifying the structure, reducing wear and smooth shifting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

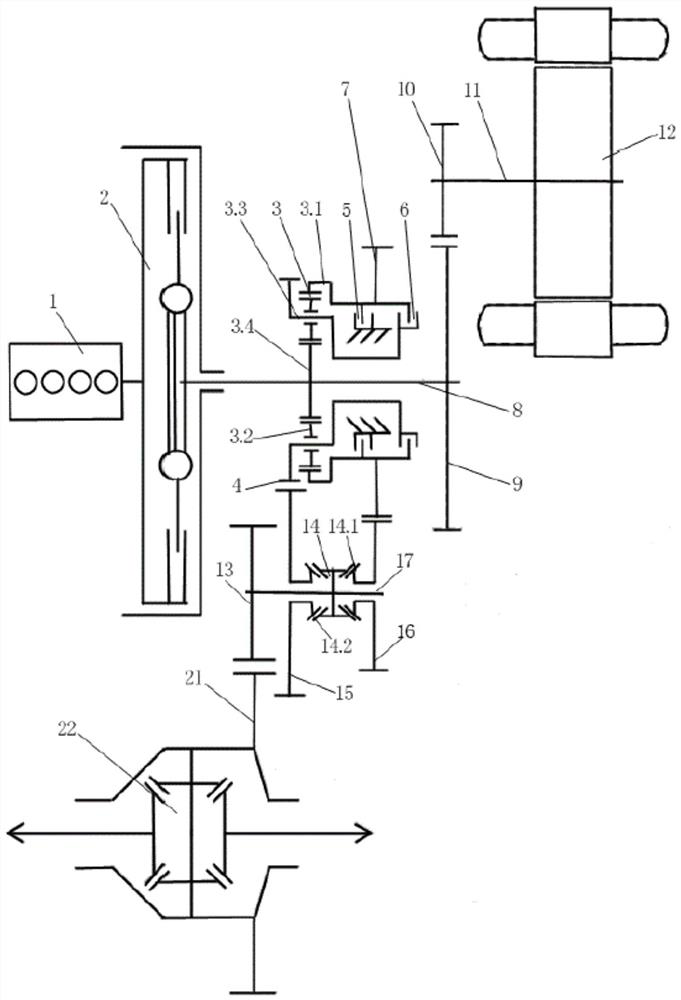

[0025] Such as figure 1 As shown, a hybrid vehicle drive system that utilizes motor speed regulation when shifting gears includes an engine 1, a motor one 12, a planetary gear mechanism 3 and a synchronizer 14, and the engine 1 is connected to the transmission shaft 8 of the engine through a torsional shock absorber 2 The planetary gear mechanism 3 includes a sun gear 3.4 fixedly connected to the drive shaft 8 of the engine, an outer ring gear 3.1 connected to the gearbox housing through a brake 5, a planetary carrier 3.3 connected to the outer ring gear 3.1 through a clutch 6, and is located at The planetary gear 3.2 on the planet carrier 3.3 and meshed with the sun gear 3.4 and the outer ring gear 3.1 respectively, the synchronizer 14 is fixedly connected to the intermediate shaft 17, and the left joint end 14.2 of the synchronizer and the right joint end 14.1 of the synchronizer can respectively be connected with the Gear 1 15 and gear 2 16, which are vacantly sleeved on th...

Embodiment 2

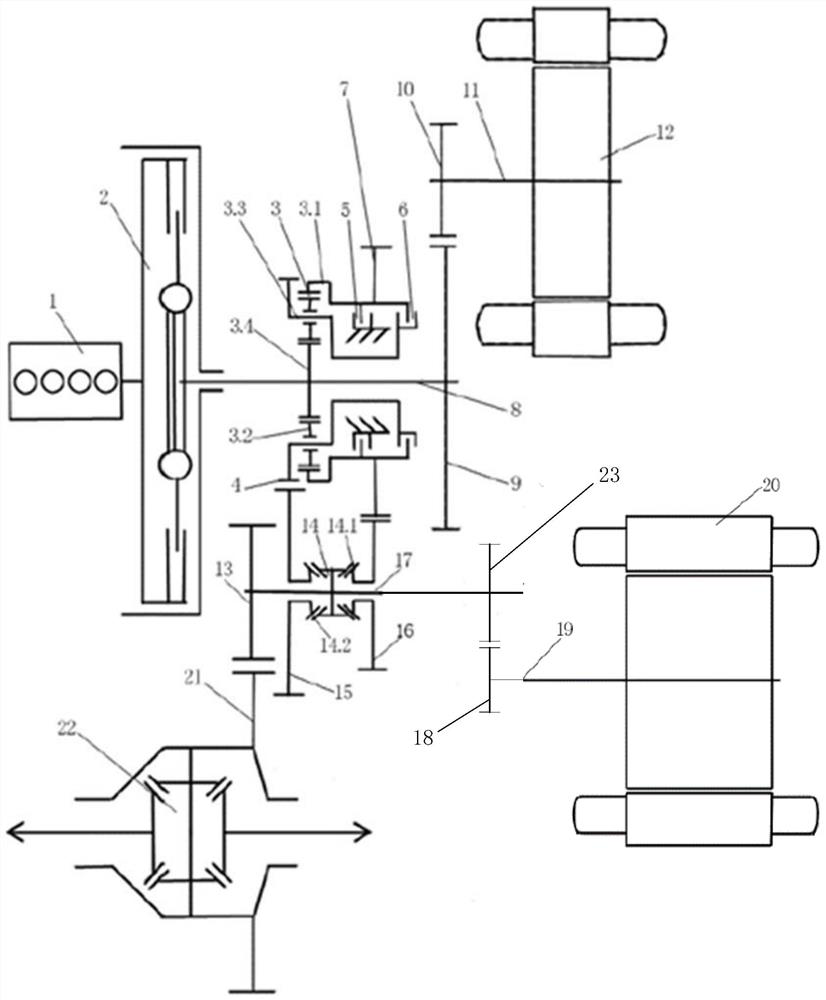

[0040] Such as figure 1 As shown, a hybrid vehicle drive system that utilizes motor speed regulation when shifting gears includes an engine 1, a motor one 12, a motor two 20, a planetary gear mechanism 3 and a synchronizer 14, and the engine 1 communicates with the engine through a torsional shock absorber 2. The transmission shaft 8 is connected, and the planetary gear mechanism 3 includes a sun gear 3.4 fixedly connected to the transmission shaft 8 of the engine, an outer ring gear 3.1 connected to the gearbox housing through a brake 5, and a planetary carrier connected to the outer ring gear 3.1 through a clutch 6 3.3. The planetary gear 3.2, which is set on the planet carrier 3.3 and meshes with the sun gear 3.4 and the outer ring gear 3.1 respectively, the synchronizer 14 is fixedly connected to the intermediate shaft 17, and the left joint end 14.2 of the synchronizer and the right joint end of the synchronizer 14.1 can be respectively engaged with gear one 15 and gear t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com