Enhancing porous tantalum implant selective laser preparation method and implant

A technology of laser selection and laser selection melting, applied in the field of material manufacturing, can solve the problem of increased oxygen content in powder, and achieve the effects of strong adhesion, improved cell adhesion, and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

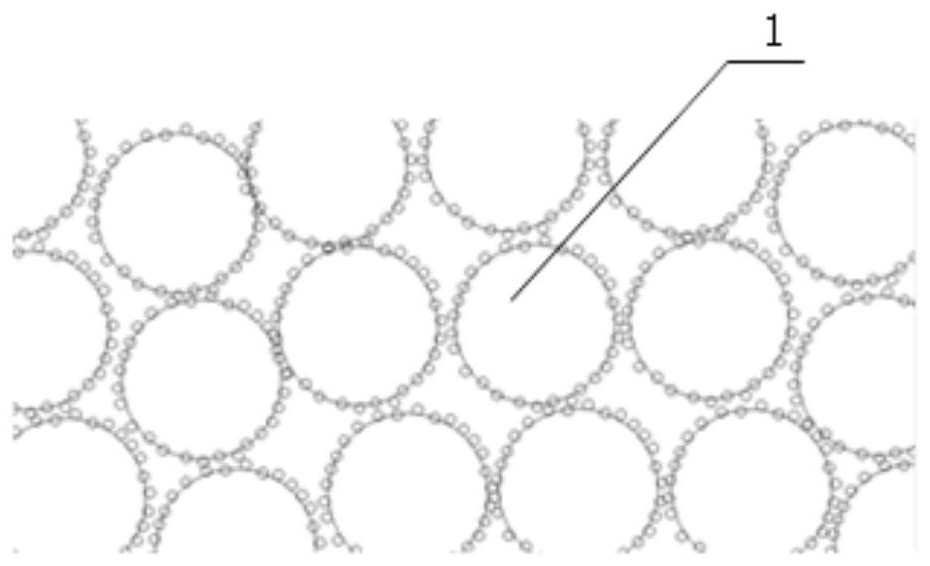

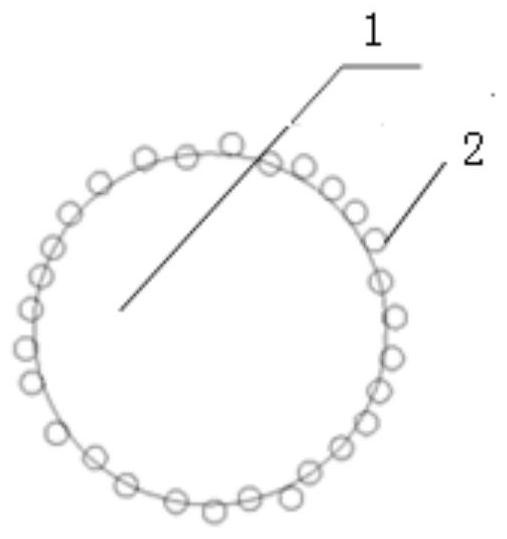

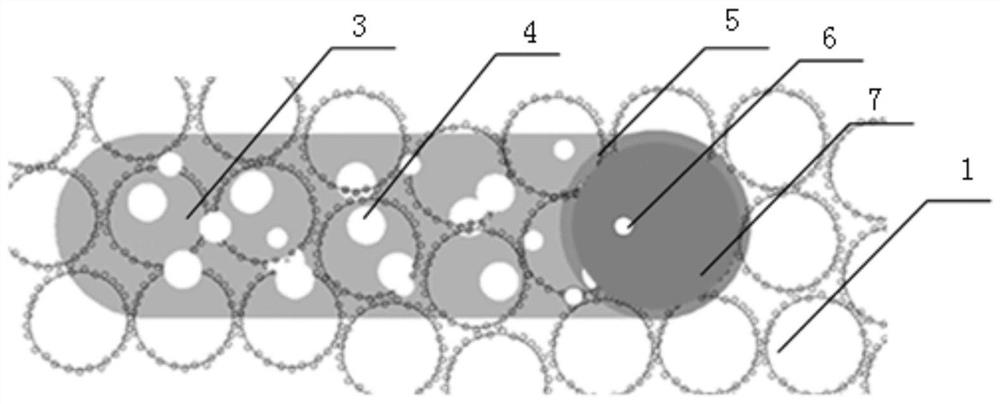

[0037] The invention forms multi-level porous tantalum under the action of laser selective melting and forming, so that the structure of the implant conforms to the personalized customization, and expands the extremely small ability of SLM forming by decomposing the augmented structure generated by hydrogen explosion overflow, and enhances the The main principle of the forming ability of laser selective melting forming porous tantalum is as follows:

[0038] Put the tantalum powder attached with nano-tantalum hydride into the selective laser melting equipment, spread the powder evenly, and then shape it with appropriate laser process parameters, where the laser process parameters include laser power, scanning speed, layer thickness, overlapping rate, etc.;

[0039] When the laser scans the tantalum powder attached with nano-tantalum hydride, the energy of the focused point melts the tantalum powder, and at the same time, the nano-tantalum hydride decomposes at high temperature,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com