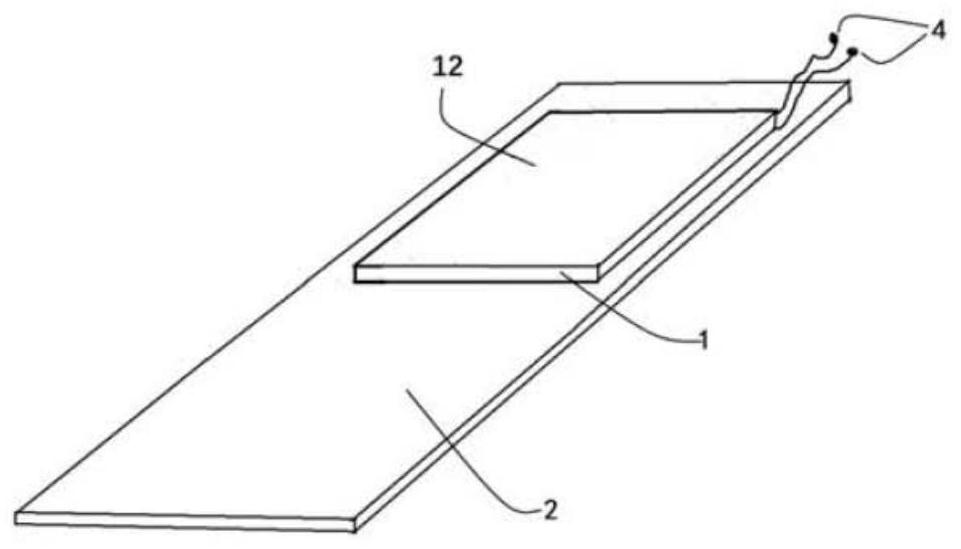

Ultrasonic atomization sheet and ultrasonic atomizer

A technology of ultrasonic atomizing sheet and one side, which is applied in the direction of spraying devices, liquid spraying devices, tobacco, etc., and can solve problems such as weak vibration, low atomization efficiency of ultrasonic atomizing sheets or ultrasonic atomizers, and easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0096] Other specific examples are: one-component systems such as BaTiO3, PbTiO3, KxWO3, PbNb2O6, etc.; two-component systems such as PbTiO3-PbZrO3, PbTiO3-Pb(Mg1 / 3Nb2 / 3)O3, etc.; -Pb(Mg1 / 3Nb2 / 3)O3, PbTiO3-PbZrO3-Pb(Co1 / 3Nb2 / 3)O3, K1-x-zNaxLizNO3 (such as {LiX(K1-YNaY)1-X}(Nb1-Z-WTaZSbW) O3, etc.) etc. Specific examples of composite oxides and compounds that can be used in the present invention can be found in CN1206700A. Derivatives of the substances shown in Table 1 obtained by partially substituting any of Ba, Sr, Ca, etc. for Pb, or partially substituting Sn, Hf, etc. for Ti, can also be used.

[0097] The above-mentioned piezoelectric ceramic plate material can also be mixed with a polymer material to form a piezoelectric sheet. Examples of the above polymer materials are fluoroplastics (such as polyvinylidene fluoride, polytetrafluoroethylene), polylactic acid, silica gel and the like.

[0098] The piezoelectric ceramic preferably contains 0.1% by mass or less of carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com