A kind of oil-water separation filter screen and preparation method thereof

A technology of oil-water separation and filter screen, which is applied in the direction of separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of complex preparation process, low separation recovery rate, secondary pollution, etc. High, good effect and well tolerated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing an oil-water separation filter screen, comprising the following steps:

[0027] a) N,N-diethylacrylamide, [2-(methacryloyloxy)ethyl]dimethyl-(3-sulfonic acid propyl)ammonium hydroxide, crosslinking agent and initiator in Mix well in water, pass nitrogen gas to remove oxygen, and place at 1°C to 5°C to obtain gel prepolymerization liquid;

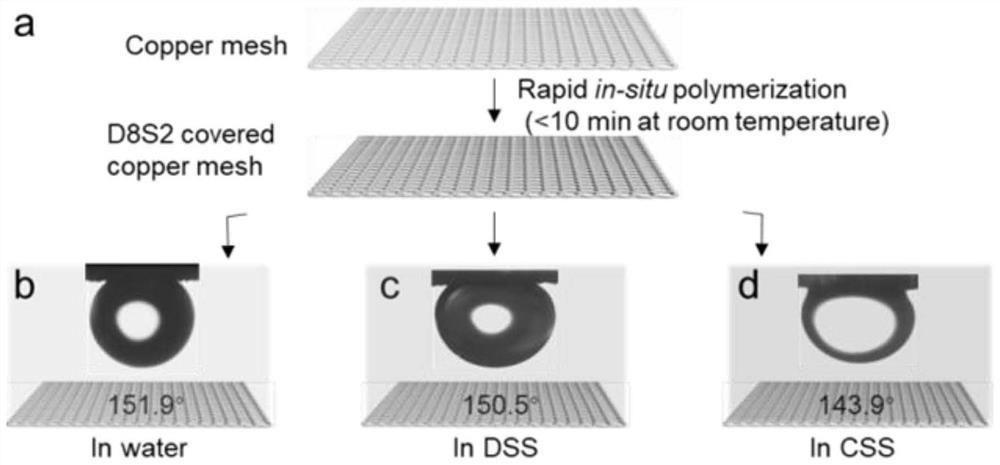

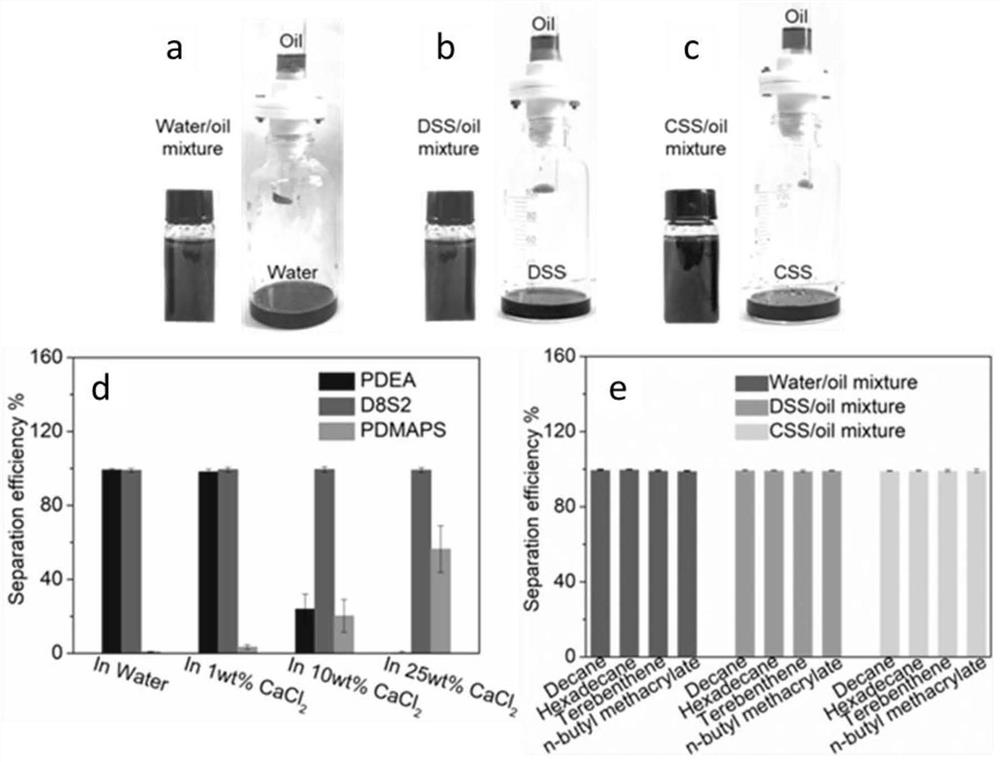

[0028] b) immersing the copper mesh in the gel pre-polymerization solution obtained in step a), and performing in-situ polymerization to obtain an oil-water separation filter.

[0029] In the present invention, N,N-diethylacrylamide, [2-(methacryloyloxy)ethyl]dimethyl-(3-sulfonic acid propyl) ammonium hydroxide, crosslinking agent and initiator Mix evenly in water, pass nitrogen gas to remove oxygen, and place at 1°C to 5°C to obtain gel prepolymerization liquid. In the present invention, the N,N-diethylacrylamide (DEA) and [2-(methacryloyloxy)ethyl]dimethyl-(3-sulfonic acid propyl)ammon...

Embodiment 1

[0054] (1) Mix N,N-diethylacrylamide (DEA) (35.34g) and [2-(methacryloyloxy)ethyl]dimethyl-(3-sulfonic acid) in a molar ratio of 4:1 Acid propyl) ammonium hydroxide (DMAPS) (64.42g), with 0.3g methylene bisacrylamide (BIS), 0.9g ammonium persulfate, dissolved in 300mL deionized water, stirred at room temperature (about 25°C) until fully dissolved , and then purged with nitrogen to remove oxygen, and stored at 4°C to obtain a gel prepolymer solution.

[0055] (2) Soak the copper mesh in 1wt% dilute hydrochloric acid for 2min to remove surface oxides, then clean it with deionized water and dry it naturally to obtain the pretreated copper mesh; then the pretreated copper mesh Immerse in the gel pre-polymerization solution obtained in step (1), and in-situ polymerize at room temperature (about 25°C) for 5 minutes to obtain a hydrogel (D8S2 for short) modified hydrophilic filter, that is, an oil-water separation filter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com