Selenium-enriched buckwheat noodles and preparation method thereof

A selenium-enriched buckwheat and selenium-enriched technology, applied in food preservation, food ingredients as antimicrobial preservation, food science, etc., can solve the problem that buckwheat noodles cannot be eaten at one time, buckwheat noodles cannot be eaten normally, mold on the surface of buckwheat noodles, etc. problem, to achieve good anti-mildew effect, non-toxic irritation, good biodegradable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A selenium-enriched buckwheat noodle is made from the following raw materials in parts by weight: 30 parts of buckwheat flour, 10 parts of selenium-enriched wheat flour, 0.03 parts of antifungal agent, 5 parts of black beans, and 5 parts of black sesame;

[0044] The selenium-enriched buckwheat noodles are made by the following steps:

[0045] Step S1: After cleaning and drying the black beans and black sesame, crush them through a 100-mesh sieve to obtain a mixed powder;

[0046] Step S2: Add buckwheat flour, selenium-enriched wheat flour, antifungal agent, and the mixed powder prepared in step S1 into a stirring tank, and stir for 20 minutes at a rotating speed of 800 r / min to prepare selenium-enriched buckwheat noodles.

[0047] Described fungicide is made by following steps:

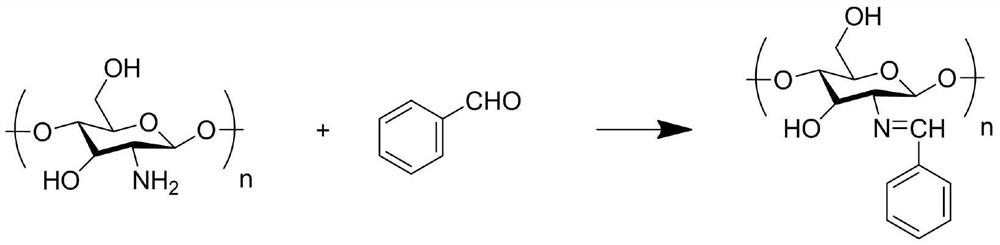

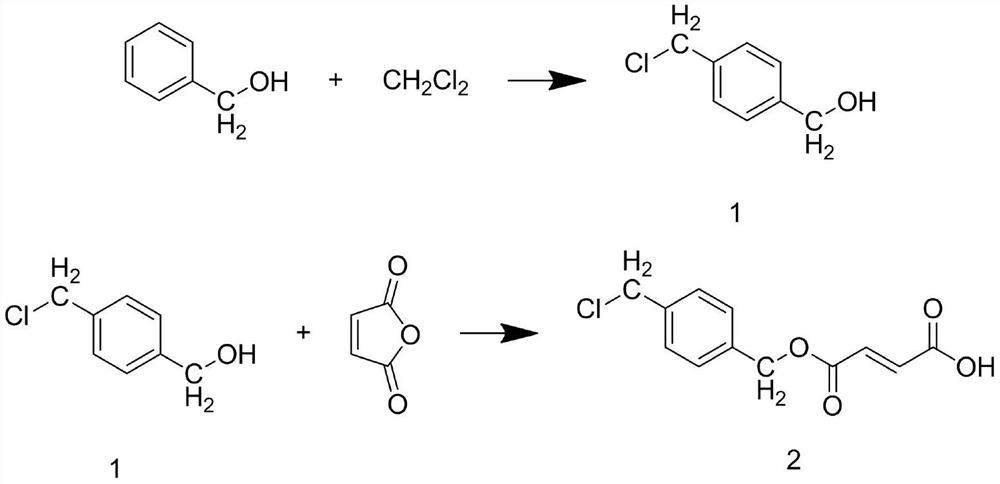

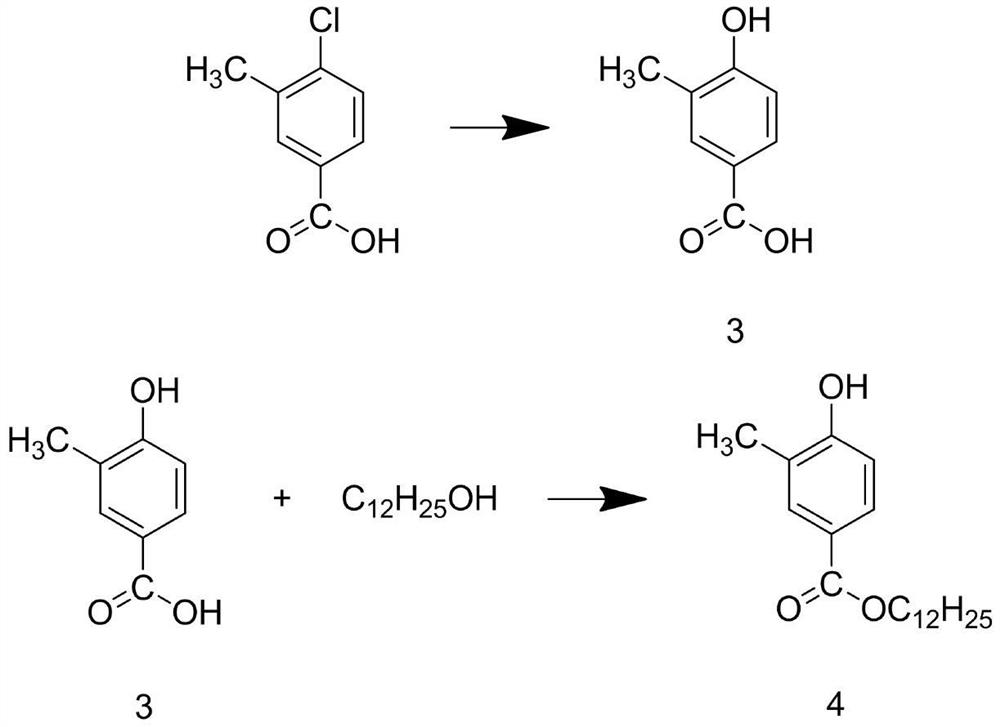

[0048] Step A1: Add chitosan, acetic acid solution, and methanol into the reaction kettle, stir until uniform at a rotation speed of 200r / min, and add benzaldehyde solution at a temperature o...

Embodiment 2

[0055] A selenium-enriched buckwheat noodle is made from the following raw materials in parts by weight: 40 parts of buckwheat flour, 13 parts of selenium-enriched wheat flour, 0.04 parts of antifungal agent, 6 parts of black beans, and 6 parts of black sesame;

[0056] The selenium-enriched buckwheat noodles are made by the following steps:

[0057] Step S1: After cleaning and drying the black beans and black sesame, they are crushed and passed through a 110-mesh sieve to obtain a mixed powder;

[0058] Step S2: Add buckwheat flour, selenium-enriched wheat flour, antifungal agent, and the mixed powder prepared in step S1 into a stirring tank, and stir for 25 minutes at a rotating speed of 900 r / min to prepare selenium-enriched buckwheat noodles.

[0059] Described fungicide is made by following steps:

[0060] Step A1: Add chitosan, acetic acid solution, and methanol into the reaction kettle, stir until uniform at a speed of 250r / min, and then add benzaldehyde solution at a ...

Embodiment 3

[0067]A selenium-enriched buckwheat noodle is made from the following raw materials in parts by weight: 50 parts of buckwheat flour, 15 parts of selenium-enriched wheat flour, 0.05 parts of antifungal agent, 8 parts of black beans, and 8 parts of black sesame;

[0068] The selenium-enriched buckwheat noodles are made by the following steps:

[0069] Step S1: After cleaning and drying the black beans and black sesame, they are crushed and passed through a 120-mesh sieve to obtain a mixed powder;

[0070] Step S2: Add buckwheat flour, selenium-enriched wheat flour, antifungal agent, and the mixed powder prepared in step S1 into a stirring tank, and stir for 30 minutes at a rotating speed of 1000 r / min to prepare selenium-enriched buckwheat noodles.

[0071] Described fungicide is made by following steps:

[0072] Step A1: Add chitosan, acetic acid solution, and methanol into the reaction kettle, stir until uniform at a rotational speed of 300r / min, and add benzaldehyde solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com